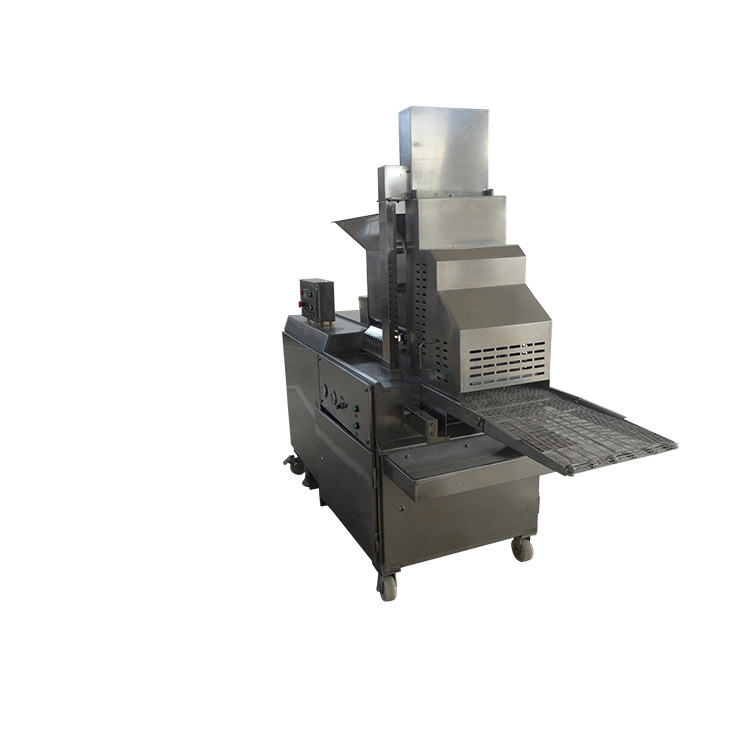

Coating Microwave Drying Machine

Coating Microwave Drying Machine:

Electromagnetic radiation drying is to use the electromagnetic induction or infrared radiation effect of microwave to heat and dry materials. Different from other external heating drying methods, this drying method is a method of uniform heating from both outside and inside of the material. Therefore, this drying method has a short time, does not deteriorate or coke due to overheating, and its drying products are of good quality, especially the drying effect of heat-sensitive food is more satisfactory.

The microwave drying machine is mainly composed of microwave generator, power supply, waveguide device, heater, cooling system, transmission system and control system. The microwave tubes used for heating and drying are mainly klystrons and magnetrons. Klystron is often used in high frequency or high power applications. Microwave generated by microwave tube is transmitted to heater through waveguide device. The heaters are mainly box type, plate type and waveguide type.

Characteristics of microwave dryer:

Microwave drying is an efficient, energy-saving, stable, reliable, simple equipment, easy operation and new technology. Microwave dryer is characterized by continuous production of equipment, only need electricity, no need for other energy, can quickly dry materials, equipment occupies a small area, pollution-free, simple operation; no need for preheating and no energy loss after shutdown. Less labor, high quality products. The advanced equipment is a high-tech product which can not be replaced by other equipment.Microwave sterilization is carried out under both thermal and non-thermal effects of microwave. Compared with conventional temperature sterilization, microwave sterilization can achieve satisfactory sterilization at lower temperature and in a very short time. Generally, the sterilization temperature is about 80 C, the treatment time is 3 - 5 minutes, and the nutrient composition can be maintained to the maximum. Retention of vitamin C by conventional heat treatment is 46%-50%, microwave can reach 60-90%, and that of vitamin A by conventional heat treatment is 58%, while microwave treatment is 84%, without affecting the original flavor. It is a good means for deep processing of fruit and vegetable food and obtaining green food.