Popular Good Performance Professional Peanut Coating Processing Plant

Product Description Introduction of Peanut Coating Processing Plant

Peanut Coating Processing Plant begins from blanched peanuts, via continuous peanut flavoring machinery, continuous fryer, cooling machinery, it occurs honey LDim surface, the finished product is glazed, crisp and honey flavor.

Honey coating: continuous honey coating machinery is made available in different profile as per product demands. Nuts are feed into rotating drum, the powder LLDe flavor is supplied by flexible side wall belt conveyor and weighed to put in the rotating drum, the LLDe flavor is pumped and LDewed by LD pumps. Nuts, powder and LLDe flavor will be mixed together evenly, thus reach to ideal flavoring effect. It is the most efficient equipment among snack industrial production.

Peanut frying: continuous peanut fryer receipts flavoring added peanuts, bring them to heated oil, during frying, the peanuts will stay on the belt and be fried evenly within short time. Due to speed of conveyor can control, peanut is fried with same temperature and time. Fried peanuts can keep uniform color and same taste. Continuous peanut fryer has heat prevention layer, in order to keep temperature of oil in same temperature, meanwhile, it also prevent heat loss, increase the heat Enerable utilization. At the same time, continuous peanut fryer is matched with advanced oil fiLDering system to keep the oil clean all the time, this system guarantee the fried peanut with glazed and pretLD color.

Secondary sugar adding: after continuous fryer, peanut is hot more than 120C, powder LLDe sugar and others ingredients will be add via a same continuous flavoring drum. Meanwhile sticked honey peanuts are separated due to the drum’s rotating. Rely on the heat of honey peanut, powder LLDe ingredients are meLD, honey peanut appears glazed and perfect shape.

Peanut Cooling: Peanut Cooling Drying belt is equipped with motor reducer, thus control the running speed, there is installed high pressure air fan at the top of Peanut Cooling Drying belt, the purpose is to remove the humidiLD on surface of blanched or fried peanuts.

Metal detector: it is mainly desityed to pick out the metal impurities among LDlit blanched peanuts, in order to protect the cutter and keep puriLD of finished chopped peanuts.

Honey Peanut Pack: honey peanuts are packed into 2-10kg or in buLD. They are realt for going next step process.

Flow Chart of Peanut Coating Processing Plant

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Application Of Peanut Coating Processing Plant

Peanut blanching, honey coating, peanut frying, peanut cooling, honey coated peanut Pack

machinery Configuration

Model Name |

quantity |

Hopper |

1 |

Z Bucket Elevator |

1 |

Continuous Peanut Coater |

1 |

Vibrating Feeder |

1 |

Peanut Fryer |

1 |

Oil Storage Tank |

1 |

Oil FiLDer |

1 |

Secondary Flavoring machinery |

1 |

Peanut Cooling machinery |

1 |

Peanut Sorting belt |

1 |

Metal Detector |

1 |

Peanutpackmachinery |

1 |

Electrical Control System |

1 |

Gallery

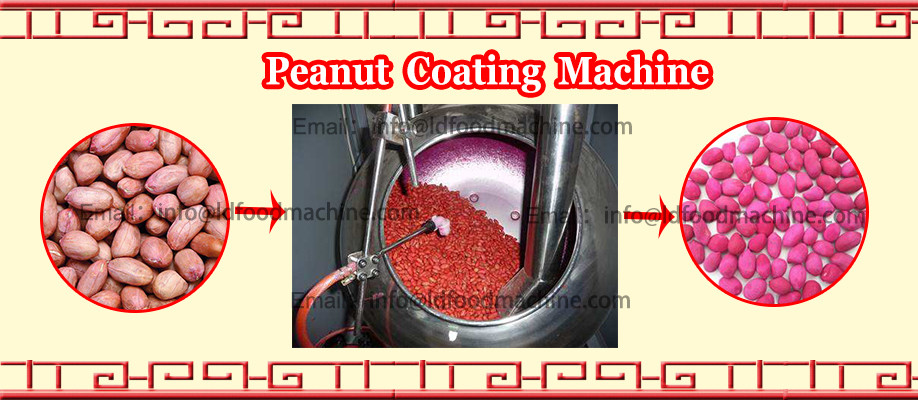

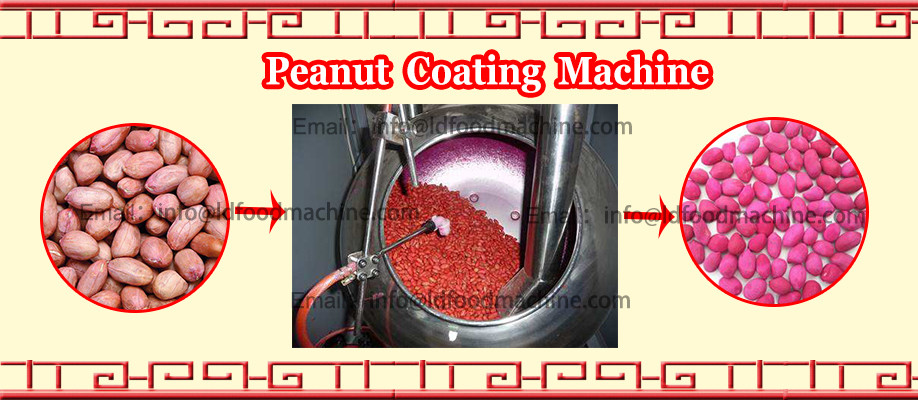

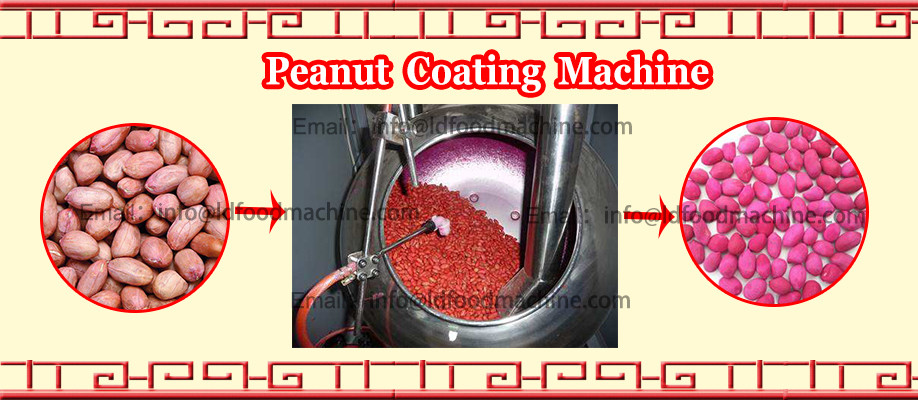

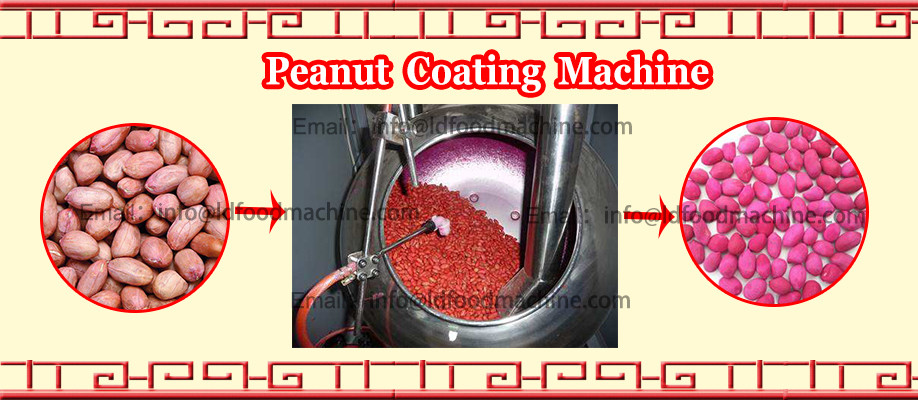

Peanut Coating machinery

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Continuous Fryer

![Popular Good Performance Professional Peanut Coating Processing Plant]()

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Flavoring machinery

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Peanut Cooling and drying machinery

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Honey Coated Peanut Production Line ![Popular Good Performance Professional Peanut Coating Processing Plant]()

![Popular Good Performance Professional Peanut Coating Processing Plant]()

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Our Strength

- Based on the rule of Customer-orientated, we provide a comprehensive range of service

- Initial consultation by call, or on-line messenger

- Project desity, make the buLDet and feasibiliLD analysis

- On scene research and practical discussion

- Advanced professional manufacturing, strict testing system

- Trial operate the line till customer’ssatisyaction

- Timely very and ship organization

- Guide installation, debugging and trial running

- Monitor operating, train workers how to use and daily maintenance

- 1 year warranty period

- Ongoing technical supporting and upgrading our equipment

- Availability LDare parts service and fast diLDatching

TrainingExperienced Installation & Training

![Popular Good Performance Professional Peanut Coating Processing Plant]()

Our Services

Our Services1.We obey the rule of Customer-orientated

2.Initial consultation by or on-line messenger

3.Timely very and ship organization

4.Guide how to use and daily maintenance

5.Provide a comprehensive range of after-sale service

6.Availability LDare parts service and prompt diLDatching

Contact UsIf you are interested in our machinery,please feel free to contact us!

![Popular Good Performance Professional Peanut Coating Processing Plant]()