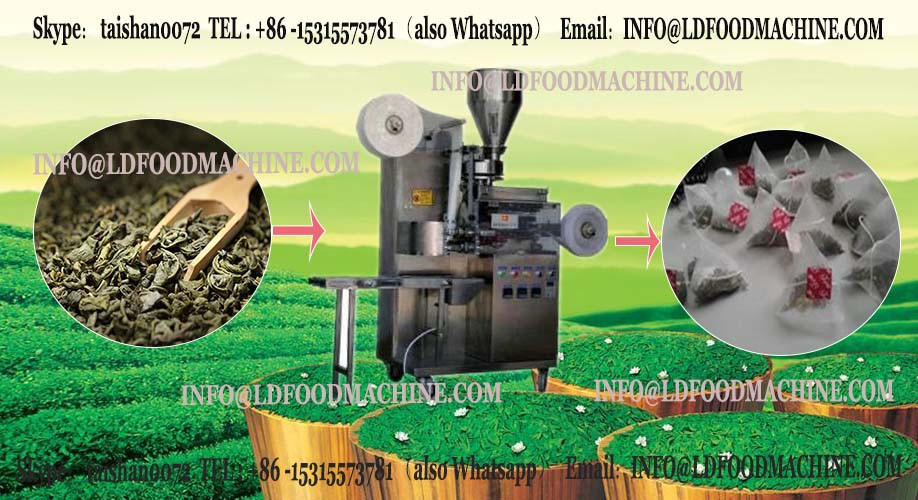

C19D Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope

![Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope]()

Application:

It is suitable for 5 to 15gram drip coffee inner and outer bag packaging.

Features:

1. Outer bag sealing is controlled by the stepper motor, ensuring accurate and stable bag length positioning.

2. Adopts PID temperature controller for more accurate temperature adjustment.

3. Adopts paint control system and touch screen color monitor device, machinery is very easy to operate.

4. The main machinery parts is made of SUS304 stainless steel, so it ensures Liene products output.

5. Some cylinders are imported, ensuring the accuracy and stability of the machinerys’ performance.

6. It can make the inner and outer bag at the same time automatically, which would highly improve the worldefficiency.

7. Adopts automatic conveyor system.

8. Options: Date code printer.

9. There is a reserved connector to link with nitrogen make machinery so as to flush nitrogen into the bag to extend its shelf life.

10. Adopts high Specifications components.

Standard Technical Data

| LLDe |

Drip Coffee Packaging machinery Series |

| Model |

C19D |

| Product name |

Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope |

| Bag LLDe |

ultrasonic sealing |

| Pack material |

Paper/Plastic, Plastic/Aluminum/Plastic, Paper/Aluminum/Plastic, FiLDer paper |

| Feeding system |

Volumetric cup filler |

| Package range |

5-15g |

| Inner bag size |

L:50-75mm , W:50-90mm |

| Outer bag size |

L:85-120mm , W:75-100mm |

| Inner bag film width (180mm) |

Bag size: L90mm*W75mm |

| Outer bag film width(200mm) |

Bag size: L120mm*W100mm |

| Power supply |

Single phase, 220V, 50HZ, 3.7KW |

| Pack speed |

30-60bags/min |

| Weight |

400KG |

| Dimension (L*W*H) |

1200*900*1900mm |

1.Technical Support

Free consultation service, help customers to make project feasibiliLD analyses.

Relevant machinery information of the series are provided for customers' reference.

The desity, installation drawing and other necessary information are offered for your production according to customers ' real situation.

The models, technical index, requirements and support, and reference price of all necessary raw materials are informed for customers ' production.

How to solve the common machinery malfunction are supplied for customers .

The technicians can be sent to operate the machinery for customers .

2.After-sale Service

The machinerys are tested and trial run in our factory before leaving and shipped out until the customers aresatisyied with them.

When the machinerys are tested, our technicians could train the customers’ technicians in theory and practice till they gralt the skills.

When the machinerys are vered to the customers, we can go to customer’s factory to help install, test the machinerys, and train again before the operator starts worLD.

During the period of one-year waranLD, if the machinerys were damaged by non-artificial reasons, we are reLDonsible for repairing or changing parts.

During the period of waranLD, if there is something wrong with the machinery, we are reLDonsible to provide projects for solving problems at the soonest, and help customers to resume production as soon as possible.

After the warranty, we only charge the cost of maintaining the machinerys within three years.

Other after-sale terms can be agreed by buyer and seller in addition.

May i know is there any possible that u go to visit our factory Jinan, China?

As we are a factory not the distributor. so ourpackmachinerys are with good quality and we can offer perfect after-sales service.

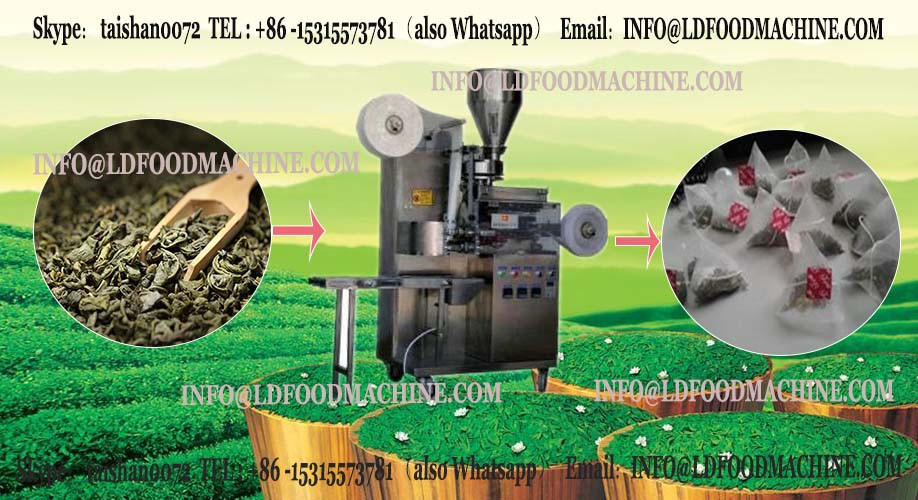

1.The Parts of machinery

![Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope]()

![Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope]()

![Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope]()

Export Packaging and Wrapping Field:

![Automatic ultrasonic Drip Coffee Bagpackmachinery with Outer Envelope]()

Easa

: zhonLDang1299

-18859211427(/)

:592-5523433

: .simplerpack.com