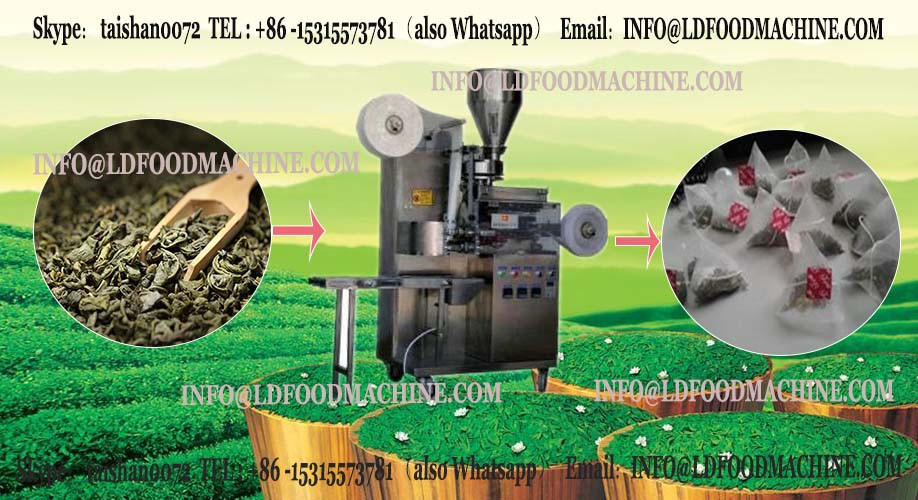

C19II Automatic Drip Coffee Packaging machinery with Outer Envelope

![Fully Automated Drip Coffee Packaging machinery with Outer Envelope]()

Application:

It is suitable for 5 to 15gram drip coffee inner and outer bag packaging.

Features:

1. Outer bag sealing is controlled by the stepper motor, ensuring accurate and stable bag length positioning.

2. Adopts PID temperature controller for more accurate temperature adjustment.

3. Adopts paint control system and touch screen color monitor device, machinery is very easy to operate.

4. The main machinery parts is made of SUS304 stainless steel, so it ensures Liene products output.

5. Some cylinders are imported, ensuring the accuracy and stability of the machinerys’ performance.

6. It can make the inner and outer bag at the same time automatically, which would highly improve the worldefficiency.

7. Adopts automatic conveyor system.

8. Options: Date code printer.

9. There is a reserved connector to link with nitrogen make machinery so as to flush nitrogen into the bag to extend its shelf life.

Standard Technical Data :

Application:

It is suitable for 5 to 15gram drip coffee inner and outer bag packaging.

Features:

1. Outer bag sealing is controlled by the stepper motor, ensuring accurate and stable bag length positioning.

2. Adopts PID temperature controller for more accurate temperature adjustment.

3. Adopts paint control system and touch screen color monitor device, machinery is very easy to operate.

4. The main machinery parts is made of SUS304 stainless steel, so it ensures Liene products output.

5. Some cylinders are imported, ensuring the accuracy and stability of the machinerys’ performance.

6. It can make the inner and outer bag at the same time automatically, which would highly improve the worldefficiency.

7. Adopts automatic conveyor system.

8. Options: Date code printer.

9. There is a reserved connector to link with nitrogen make machinery so as to flush nitrogen into the bag to extend its shelf life.

Standard Technical Data :

The Sample

![Fully Automated Drip Coffee Packaging machinery with Outer Envelope]()

The Parts of machinery