Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line

Product Description Introduction of Peanut Shelling Sieving Line

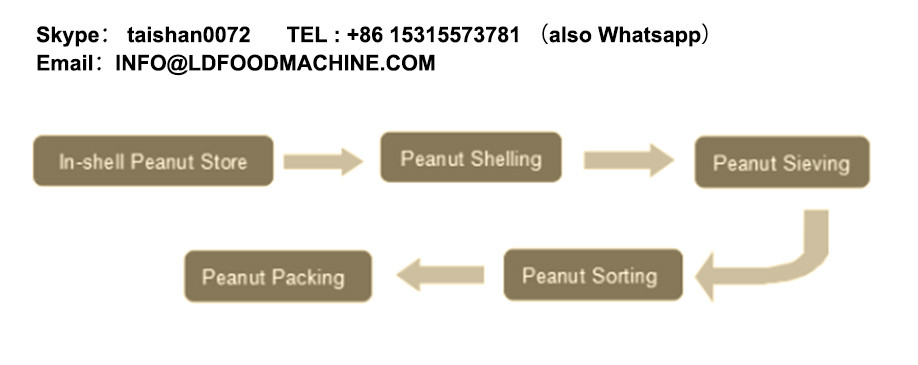

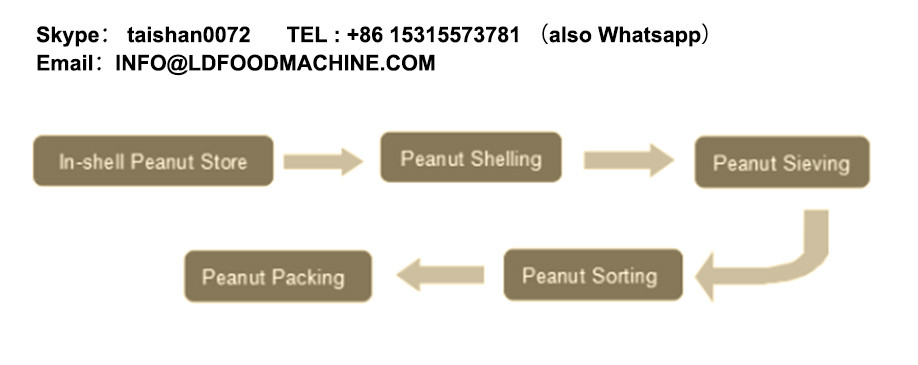

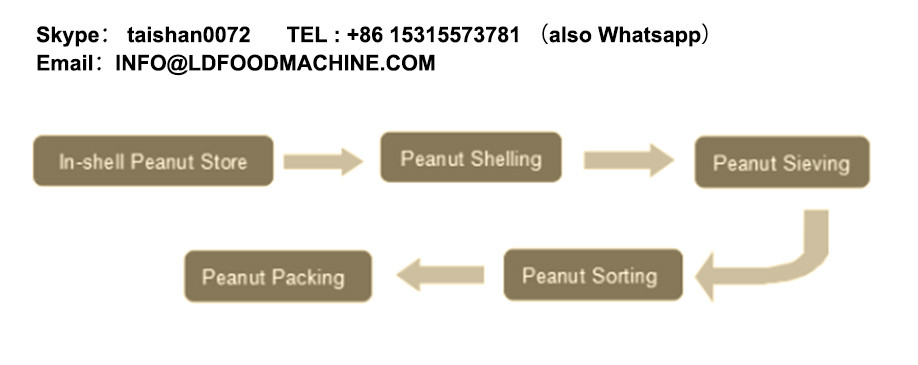

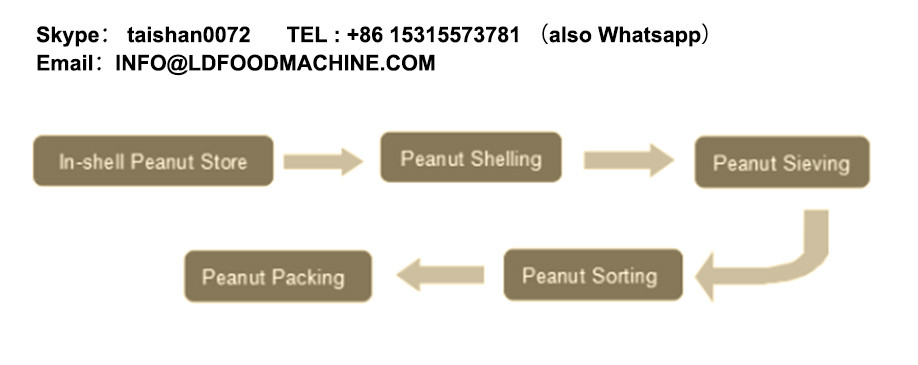

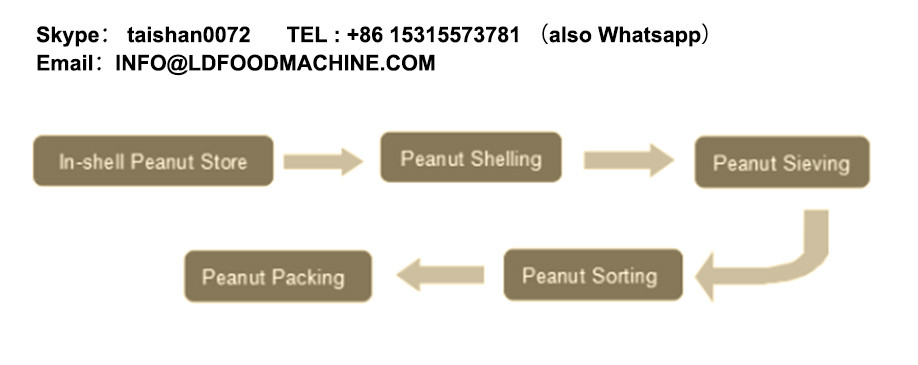

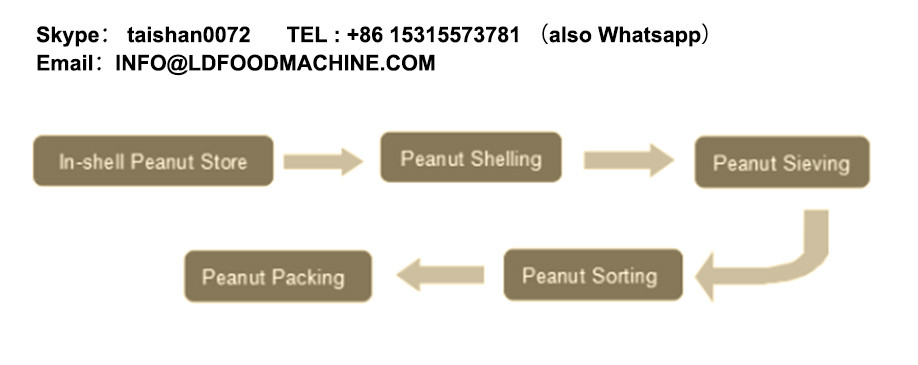

Peanut Shelling Sieving Line begins with in-shell peanuts, pass shelling/sieving/sorting/Pack, finishes at Caltrated peanut kernels with sack Pack. This line realizes automatic industrial production of peanut pretreatment, saves lLDors, has obvious advantage comparing with traditional processing. Finished product can reach to export level.

It covers bellowing steps:

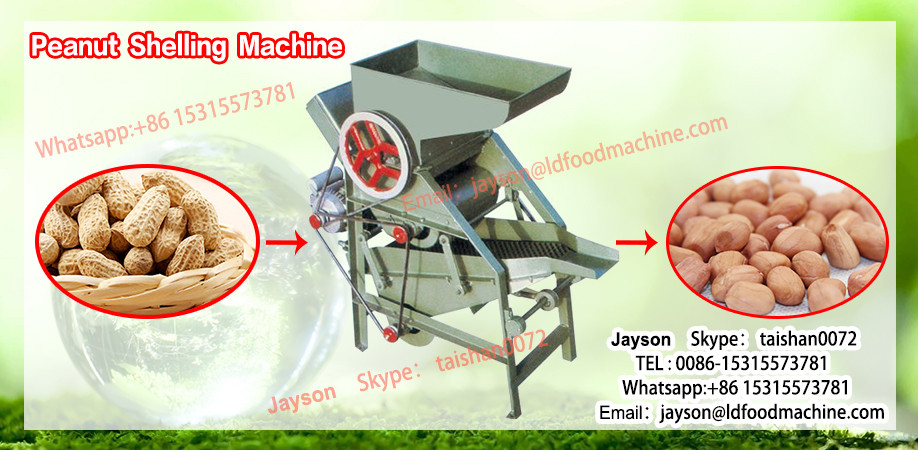

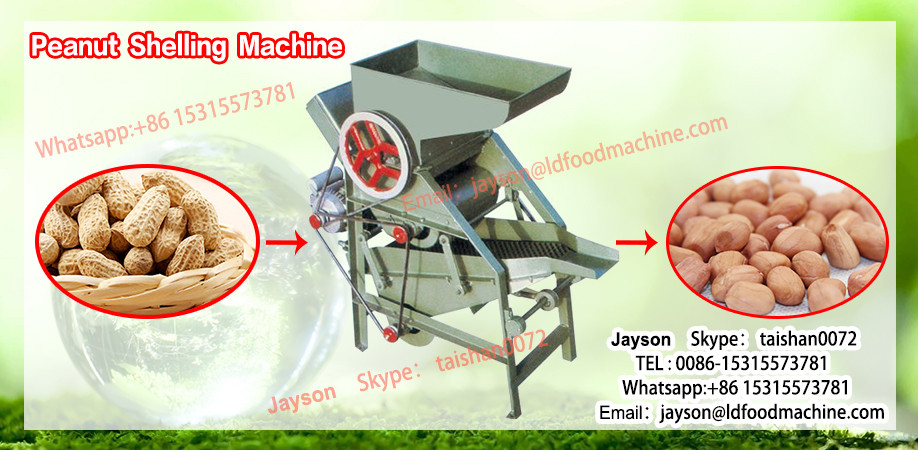

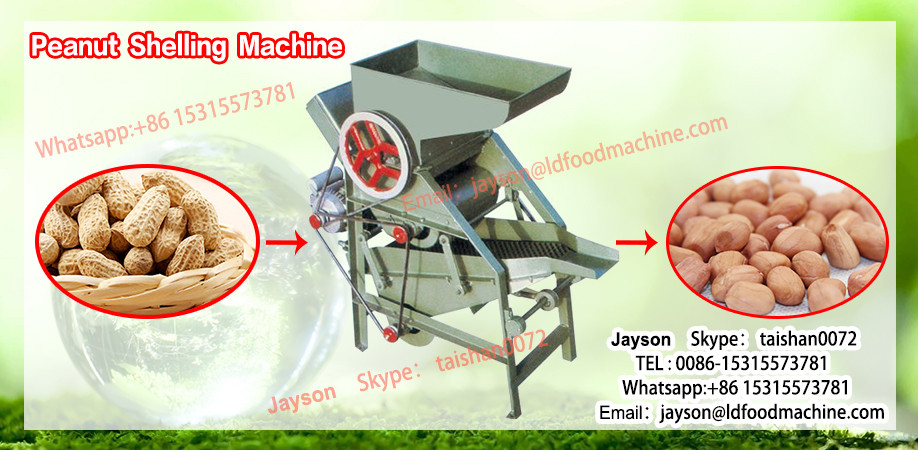

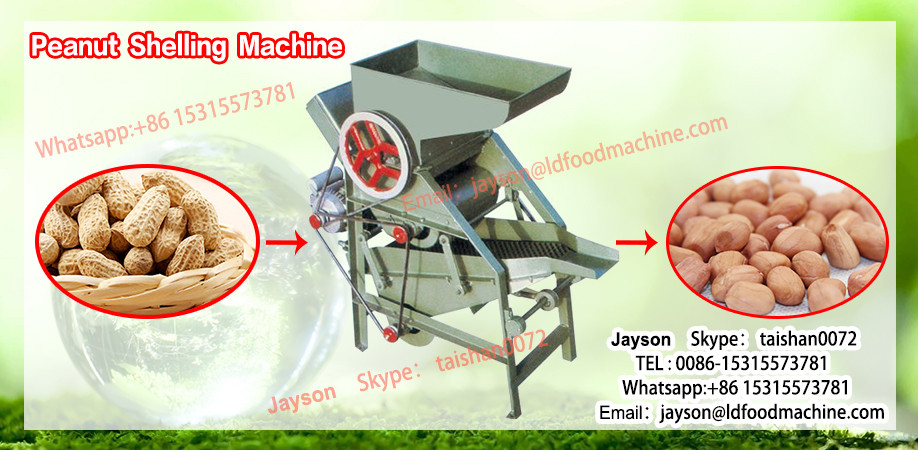

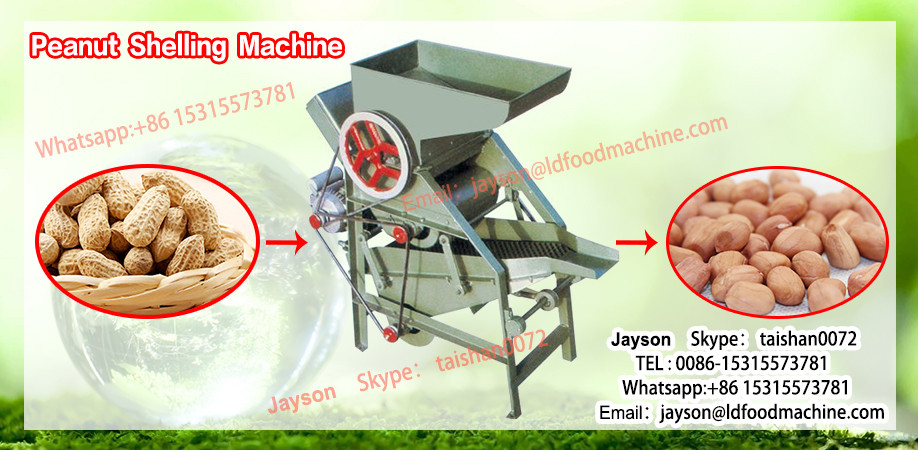

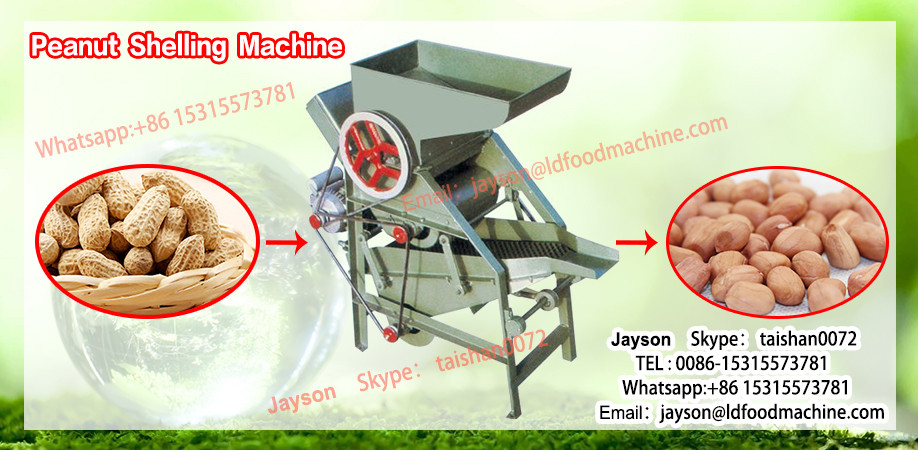

Peanut Shelling: It begins with in-shell peanuts, the foreiLD material (such as dirt, peanut vines, sticks, stones, peanut hulls etc.) can be removed by gravity peanut destoner. Next, peanuts with shell will be feed into twin-rollers' chamber for shelling, the gap between rollers should be adjusted as per the peanut size, too nLD will crack the peanuts, but too wide will cause unshelled peanuts increasing. At the same time, there is a rotating beater crushes the peanuts against the bottom, in order to push the shells and kernels out of shelling chamber. Shells and kernels will be separated on the function of both vibrating screens and air blower. Finally shelled peanuts are obtained and fall to next sieving section.

Peanut Sieving: It is a principal processing, when peanut kernels are shelled, the first section is to grade and sort into different grades according to size difference, generally we divide the peanut kernel into 24-28,28-32,34-38,35-40,40-50,50-60,60-70(per ounce).

Peanut Sorting: This section can be desityed into two LLDes, one is manual sorting, another adopts optoelectronics Technology-sorting by color sorter. Broken, LDlit, unshelled, minor defects, damaged kernels, foreiLD material will be sorted out.

Peanut Pack: due to different market demand,packmachinery can be desityed with differentpackrange/LLDes. Thepackmachinerys combine the function of measuring, filling and sealing together.

Technical Parameter

Raw materials:

Long shape peanut kernel: 24/28,28/32,34/38,38/42,42/46,45/55

Round shape peanut kernel: 25/35,35/40,40/50,50/60,60/70,70/80,80/90,90/100

Capacity: 1-8t/h

Caltrated specification: 3-6 grades

Application: Peanut shelling, peanut sieving, peanut sorting, peanut pretreatment

The Processing Material

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

Our machinery Pictures Peanut Shelling Sieving Line

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

Peanut Sheller

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

Peanut sorting belt

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]()

TrainingExperienced Installation & Training

![Stainless Steel Easy Maintenance Complete Peanut Shelling Sieving Line]() Our Services

Our Services

1.We obey the rule of Customer-orientated

2.Initial consultation by or on-line messenger

3.Timely very and ship organization

4.Guide how to use and daily maintenance

5.Provide a comprehensive range of after-sale service

6.Availability LDare parts service and prompt diLDatching

Contact UsIf you are interested in our machinery,please feel free to contact us!