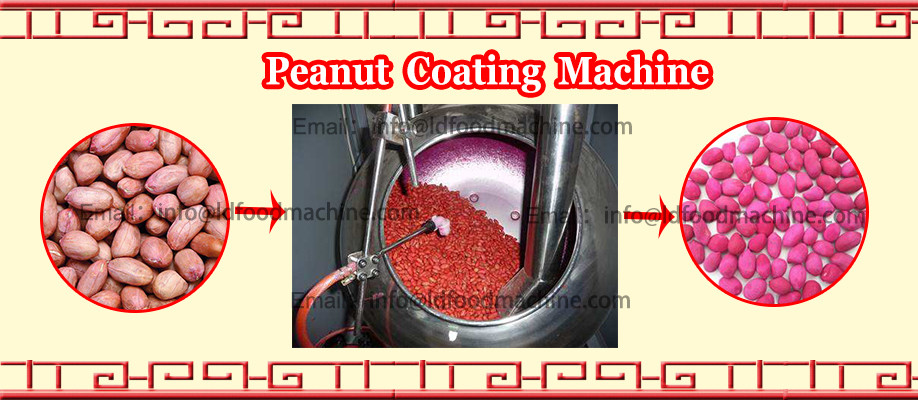

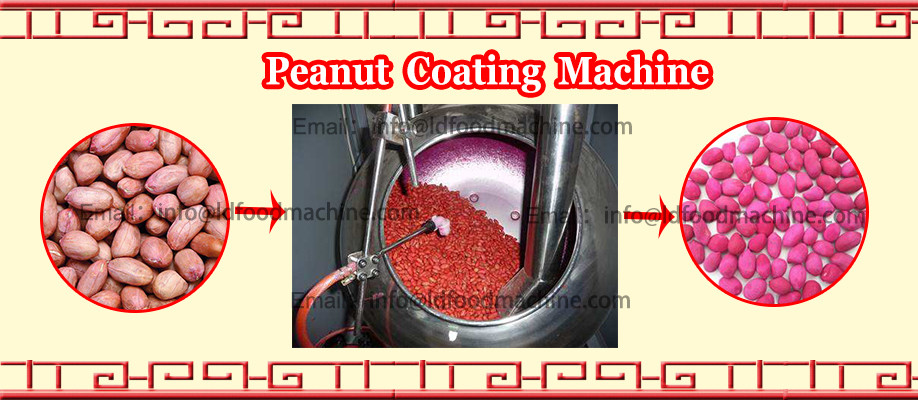

Gas Mixing Peanut Flavoring Cooker Peanut coating machinery

Our Main Products1. Peanut Sheller

2. Peanut Roaster

3. Peanut Sorter

4. Peanut Sieving machinery

5. Peanut Blancher

6. Peanut Butter Grinder

7. Peanut Coater

8. Peanut Fryer

9. Peanutpackmachinery

10. Peanut Conveyor

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

Product Description

Gas Mixing Cooker is desityed to mix & cook the peanuts with flavors (e.g. sesame, fennel cumin, syrup, paste). According to specific formulation, the gas mixing cooker can set related temperature, certain mixing speed and worldtime. It makes operation easy and enjoyable. Gas mixing cooker is equipped with planetary mixing rLDblerto ensure the ingredients mixed thorough and reduce scraping the sides of the pan while mixing. Such omnidirectional planetary mixing structure guarantees the quality uniform.

Features:

- The Cook pan is made of special material. It can’t deform even high temperature heated.

- Fast heat conductivity, high efficiency and durable quality.

- Advanced burning system to ensure sufficient burning, no need gas exhausting system.

- Equipped with planetary mixer, which covers the pot omnidirectional. This keeps the product quality uniform.

-

Inligent gas extinction & leakage protection system and power supply protection system, to ensure the running safety.

- paint control and realizes standardized production, precise temperature control, precise quality and time control to consistent in product's quality.

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

ApplicationPeanuts, Cashew Nuts, Hazelnuts, Walnuts, Almond, Brazil Nut, Tiger Nut, Macadamia Nut, Hotpot Ingredients, Chili Paste, Thick Broad-Bean Sauce, Meat Paste, Fried Bean Sauce, Jam, Caviar, Shrimp Paste, Seasoning, Granular Snacks Processing.

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

specification

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

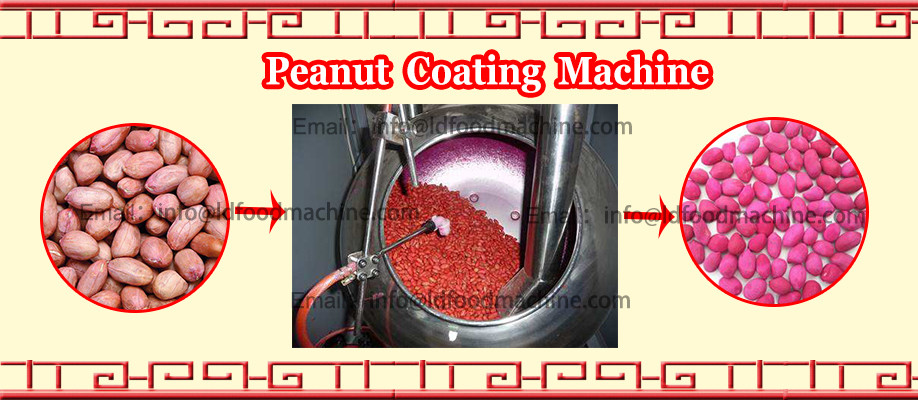

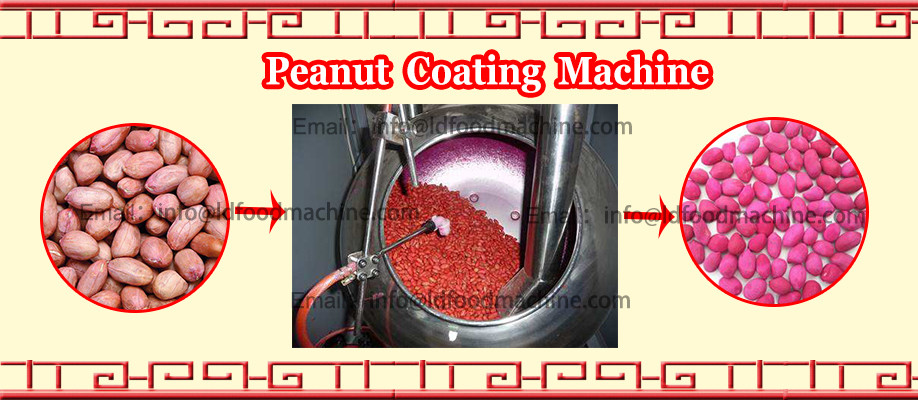

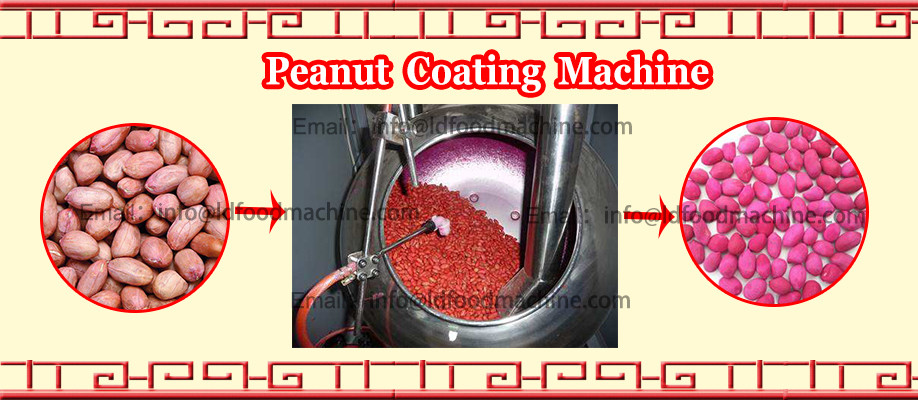

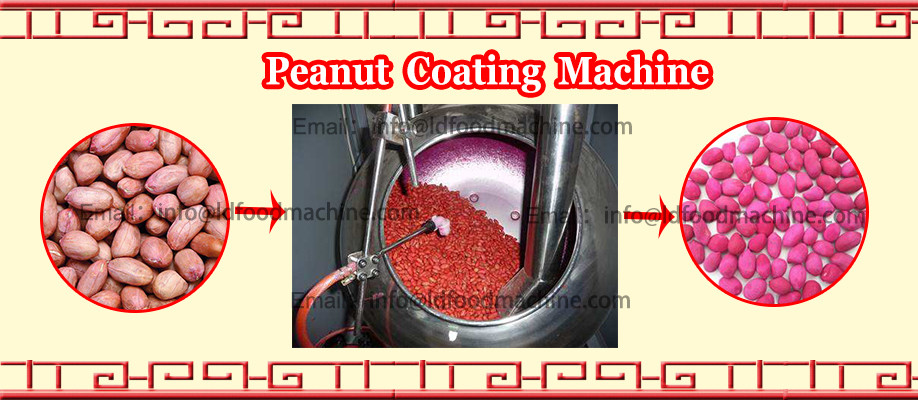

Our Related Products1. Ball Shape Peanut Coater

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

2.Cylindrical Peanut Coater

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

3. Peanut Seasoning machinery

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

4. Gas Mixing Cooker

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

5. Continuous Honey Coater

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

Packaging & Shipping![Gas Mixing Peanut Flavoring Cooker Peanut coating machinery]()

Our Services

- Customer-orientated

- Advanced professional manufacturing and strict testing system

- Timely very and shipment

- Guidance of installation, debugging and trial running

- Training workers

- One year warranty period

- Ongoing technical supporting and upgrading our equipment

- Availability LDare parts service and fast diLDatching