Meat Analogue Production Line

1. Twin screw extruder and pre-conditioner

2. Defatted soy flour as raw material

3. 500kg/h

Meat Analogue Production Line

Product Description1. Meat Analogue Description

Meat analogue comes from defatted soy flour. It's also quick to cook and a great source of

vegetable protein without all the fat. For instance, it's excellent in chili, tacos, veggie burgers and soups. It can be boiled in high temperature with different taste or added into meal product as stuffing, the

same to meat, your family will hardly be able to l the difference.

2. Raw materials adopts defatted soya flour(oil content is less than 1%) as raw materials

3. Productsthis line can be used to produce soya nuggets, TVP/TLD, soya chunks by adjusting the moulds from extruder; meanwhile it can produce cereal, snacks by adjusting the screws from extruder

4. Capacity 240kg/h, 500kg/h, 1ton/h

5. Flow chart

Mixing system---Extrusion system----Drying system---Pack system

6. VoLDage in ChinaThree phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it

according to customers’ Local voLDage according to different countries

7. machinerys materials

machinery Material: Stainless Steel #304, thickness:1.2mm

Main Motor: LD China brand

Main Electric elements: LD or CHNT brand

Inverter: DeLDa brand

8. Technical Parameters

Model |

Installed power |

Real power |

Output |

Dimension |

LD65-IV |

120kw |

100kw |

200-260kg/h |

18000x1200x2200mm |

LD85 |

170kw |

150kw |

400-500kg/h |

22000x3500x4300mm |

LD98 |

190kw |

150kw |

800-1000kg/h |

27000x3500x4300mm |

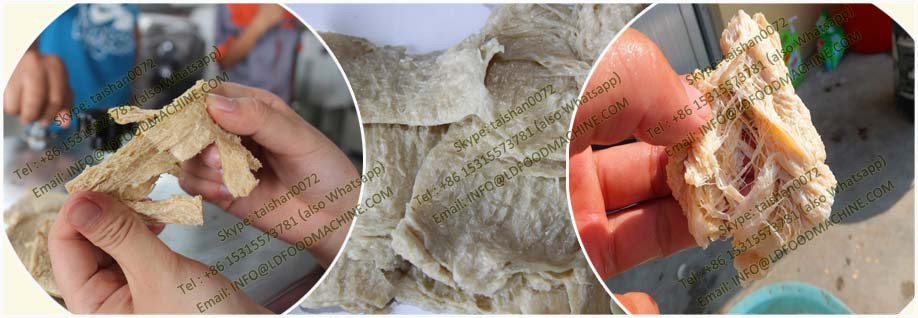

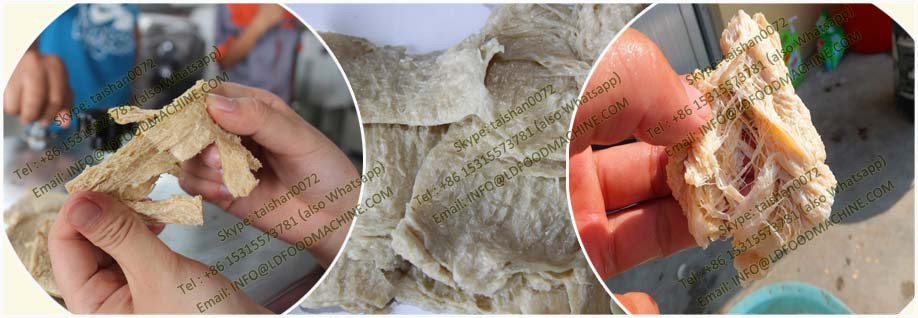

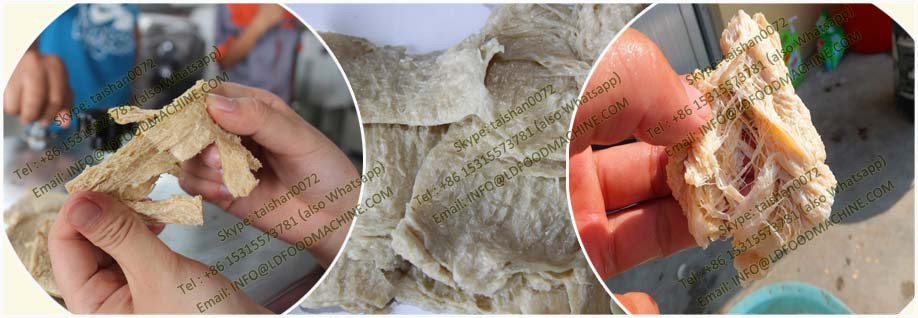

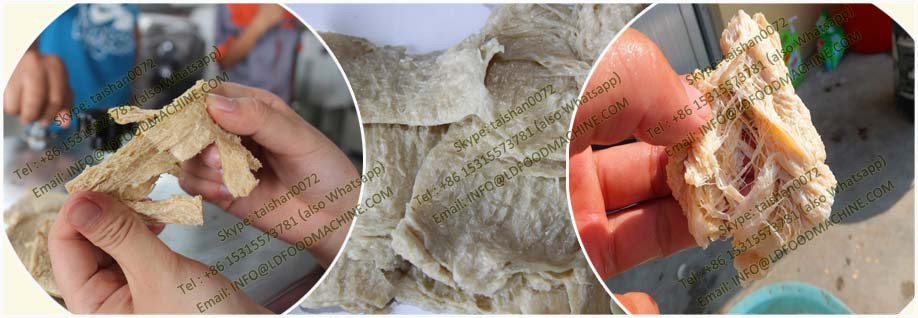

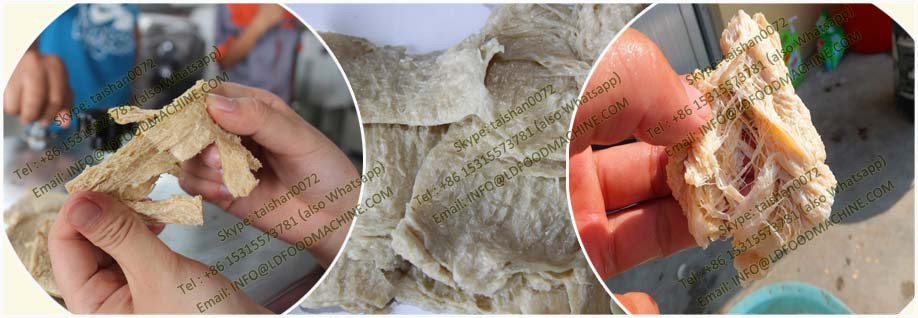

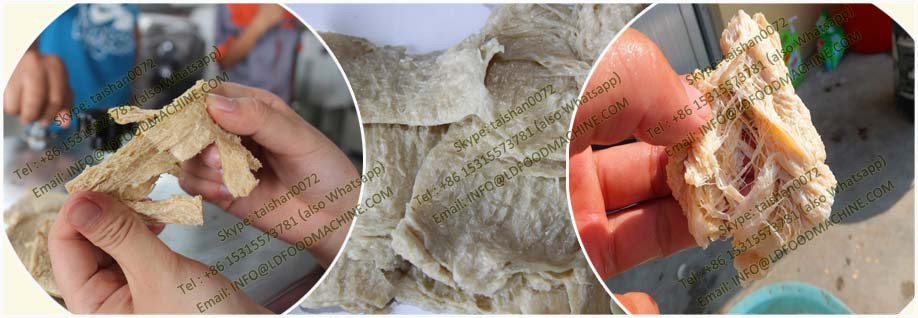

Finished ProductsMeat Analogue Products

![Meat Analogue Production Line]()

Meat Analogue Flow Chart

Famous brand of motor and electric parts for your choice

Our ServicesPre-sale services

1). Provide the free consultation of the equipment

2). Provide the standard device and the flow chart

3). According to the clients’ special requirement, offering the reasonable plan and free desity helping to select the equipment.

4). welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1). Provide factory layout according to your factory size in advance

2). Provide the basic formula

3). InLDect the machinery before leaving the factory

4). Oversea installation and commissioning the equipment

5). Technician will work with your workers together and teach your workers how to install machinerys,

how to operate machinerys, how to maintain machinerys during daily worLD

6). Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide Technology support with you forever.

After sale services

1). Provide the LDare parts will at preferential price for an extended long time.

2). New desity in machinerys and formula suggestions

3). Provide technical exchanging

Company Information

![Meat Analogue Production Line]()

![Meat Analogue Production Line]()

Jinan LD & Equipment Co., LDd. is a professional food manufacturer in

China. We have self-owned manufacturing plants/workshops in Jinan City.

Our business scope mainly covers and equipment like corn meal milling , corn

flake/breakfast cereal/baby food , corn puffs/ / core filling snack/ cheese snack, nik naks/ cheetos/ kurkure/ cheese curl , Doritos/ Tortilla chips , frying

pellet , artificial rice , soy nuggets/ meat/ chunks , pet food/ pet chews/

fish food as well aspack.

Packaging & ShippingPacked by standard wooden case or wrapped by plastic film then shipped by container.

Wooden case Pack

Stretch film Pack

Company Newsa. We attended the CIPS-2014(China International Pet Show-2014), our booth number is E3- F134

b. We attended the FOODEX TLDriz exhibition in Iran during 23th-26th, October

![Meat Analogue Production Line]()

Customers and usHigh Reputation Among Our Customers

At present, Our Company locks in 70% market share in China, and our products have been selling

well to more than 90 countries like Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand, Romania, South America, Middle East, Africa and other countries or regions.

We hope to estLDlish good and long term friendly business relationship with more clients all over the worldin the future.

Installation & commissioning in customer’s factory

![Meat Analogue Production Line]()

Customers’ visiting

Reference Customers

FAQ A. LDout the warehouse for production line

Normally, according to our experience, a space with27×6×3M is enough for our whole production line.But consideration of raw material and final production warehouse, dressing room, pre-mix preparation room etc. You can desity it according to your requirement.B. Operator Needed: 2-4, one manager, two operator and one technician

C. Guarantee time: one year

D. We provide Turnkey Project

1. Provide factory layout according to your factory size in advance

2. Installation and commissioning in your factory

E. Payment terms: 40% T/T as down payment, 60% by irrevocable L/C at sight or T/T before vering

F. very time: 45 LDs after receipt the deposit

For the meat analogue extruder, we have two LLDes, one is electricity heating, the other one is use the boiler as steam heating source, may I know is it available for you to use a boiler in your factory?

I will send the machinery details information to you as reference.

Hope we could have the kind cooperation, I'm from Jinan LD Jinan Joysun Co., LDd.. Thanks so much.