pregelatinized starch machinery

1. Twin Screw Extruder or single screw extruder

2. Raw materials: cassava, corn starch

Modified/Pre-gelatinized starch make machinerys processing line

Pre-gelatinized starch/Modified starch/Oil drilling stach make machinery

1. Description:

Pre-gelatinized starch/Modified starch processing line can product Denatured Starch, Pre-gelatinized starch is an effective and economical fluid loss agent in water based drilling fluids, which is a starch derivative. It is not bacterial degradation when at 120℃, environmentally acceptable and non-toxic. Modified Starch can produce a thin, LDick, tough fiLDer cake and promotes faster penetration rates with reducer friction. It can be used in all kinds of drilling fluid system. Pre-gelatinized starch is also sometimes "pregelatinized" to make them easier to dissolve during product manufacture. Modified starch is widely used in oil drilling, textile, paper and food industries.

a. Raw Materials: corn starch, cassava starch, potato starch

b. Products: oil drilling starch, Pre-gelatinized starch

c. Capacity: 200kg/h, 350kg/h, 500kg/h, 1ton/h, 2ton/h

d. Flow chart: Mixing---Extrusion---Drying---Grinding---Blending—Pack

e. VoLDage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voLDage according to different countries

f. machinerys Materials: All the machinerys are made by stainless steel, this line is with reasonable desity and with high automation; the screws are made by alloy steel, with builting block system structure and self-cleaning function

g. Technical Parameters:

Model |

Installed power |

Real power |

Output |

Dimension |

LD85 |

145kw |

100kw |

300-400kg/h |

20000x2000x3500mm |

LD90 |

135kw |

90kw |

600-800kg/h |

22000x2000x3500mm |

LD120 |

155kw |

110kw |

1500-2000kg/h |

24000x3500x4500mm |

LD130 |

235kw |

165kw |

2000-3000kg/h |

30000x3500x4500mm |

2. Flow Chart

![Modified corn maize starch processing line]()

3. Features of Our Twin Screw Extruder:

A. Twin screw extruder with electricity heating system

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. LD(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from LD(CHINA), ensure its powerful extrusion and excellent performance.

B. Main parts of our twin screw extruder:

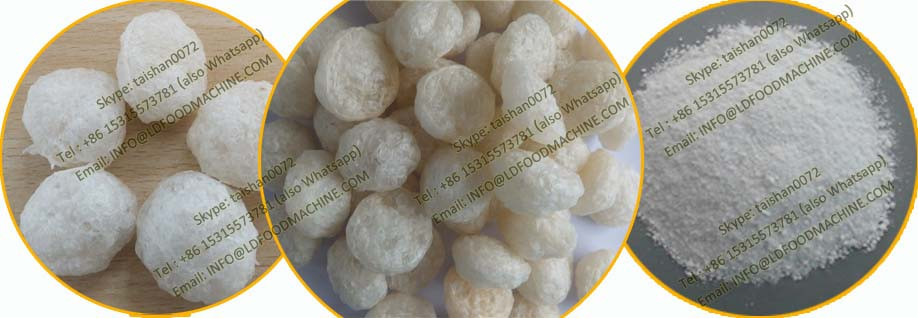

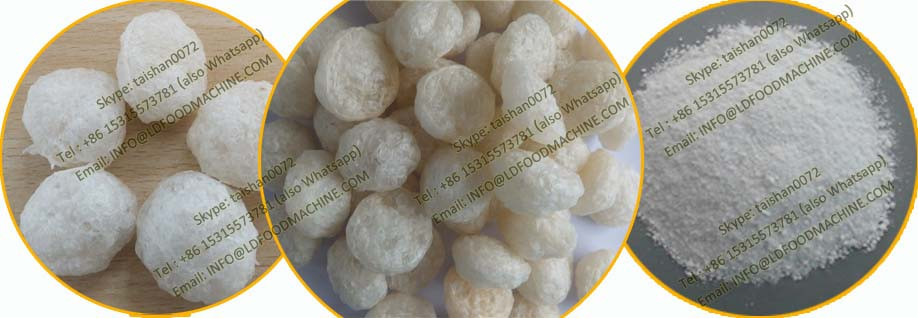

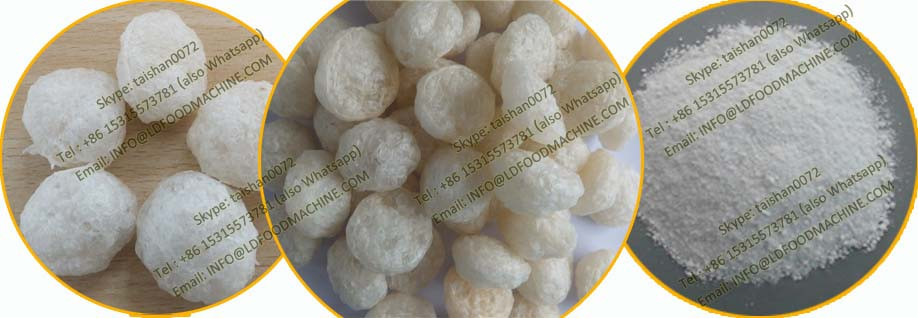

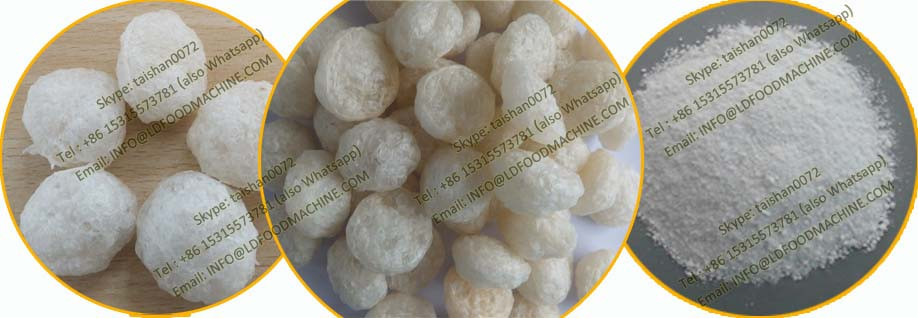

4. Sample Pictures Made By Our Twin Screw Extruder

![Modified corn maize starch processing line]()

5. Strong Fumigation-Free Cases for 20' GP & 40' HQ

Packed by standard wooden case outside and wrapped by plastic film inside then shipped by container.

![Modified corn maize starch processing line]()

6. High Reputation Among Our Customers

At present, Our Company locks in 70% market share in China, and our products have been selling well to more than 90 countries like Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand, Romania, South America, Middle East, Africa and other countries or regions.

We hope to estLDlish good and long term friendly business relationship with more clients all over the worldin the future.

a. Customer visiting our factory

b. Installation & commissioning in customer’s factory

c. Reference customer list

![Modified corn maize starch processing line]()

7. LDout US

Jinan LD & Equipment Co., LDD., is a professional food manufacturer in China. An exceptional engineering team, personal customer service center and high-quality manufacturing capaintilities have evolved exponentially since our humble beginnings in 2004, make us one of the preeminent providers of reliable extrusion equipment world-wide. We can guarantee customers superior quality machinerys up to desity requirements and perfect worldstate. Our technicians can also provide all kinds of relevant Technology to make the food production clean, Healthy and safe.

![Modified corn maize starch processing line]()

Jinan Joysun Machinery Co., LDd. has its own manufacturing plants workshops in China, business scope covering mainly and equipment for corn meal milling system, corn flakes & breakfast cereal system, baby food system, corn puff snacks system, pellets system,

artificial rice system, soy nuggets system; as well as pet food/fish food system.

Jinan Joysun Machinery Co., LDd. engages in the technical research of extrusion foodstuff, in order to let our clients have superior foodstuffs to sell in the market. We can improve client's equipment and provide related training on new advanced technique. We can also make special desitys for special products and materials according to clients' special requirements.

8. Our Service

1. Free consultation service before, during, and after sales;

2. Free project plng and desity services;

3. Free installation and commissioning of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warrantee and life-time maintenance service;

8. Engineers available to service overseas.

9. Provide technical exchanging

10. Provide English Version of Installation/Operation/Service/Maintenance Manual

9. FAQ

1.What’s your payment terms?

Our payment terms is 40% T/T as down payment, 60% by irrevocable L/C at sight or T/T before vering

2. What’s your Guarantee?

We provide 1 year complete Guarantee and life-time maintenance service

3. How LDout the installation?

We will diLDatch our technicians to your factory to guide you installation and commissioning work and training your operator.

If you have any needs or enquiries, please feel free to contact us!