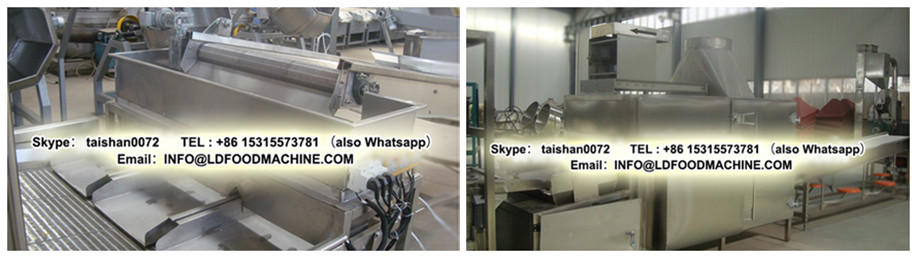

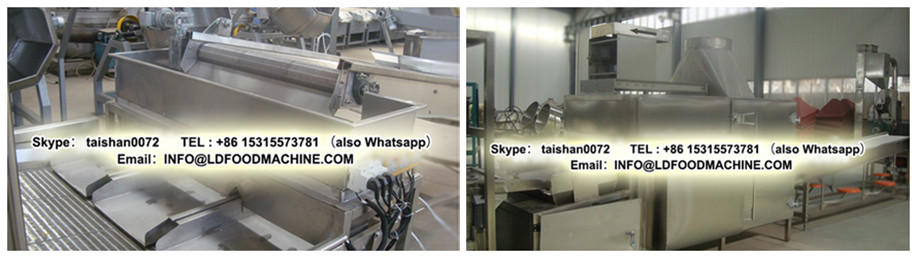

Electrical Peanut Fryer Coated Nuts Frying machinery Production Line

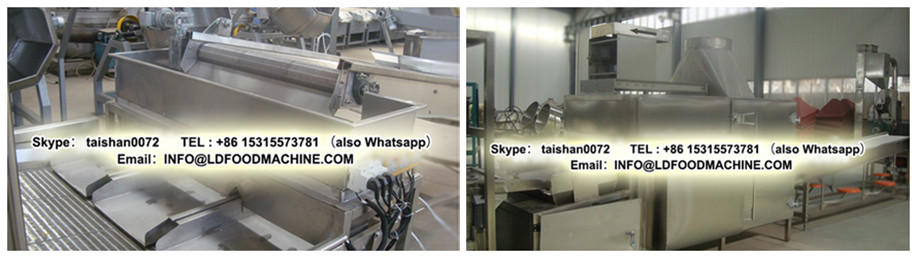

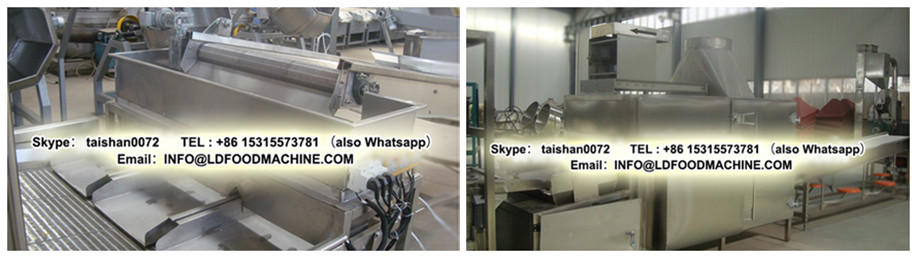

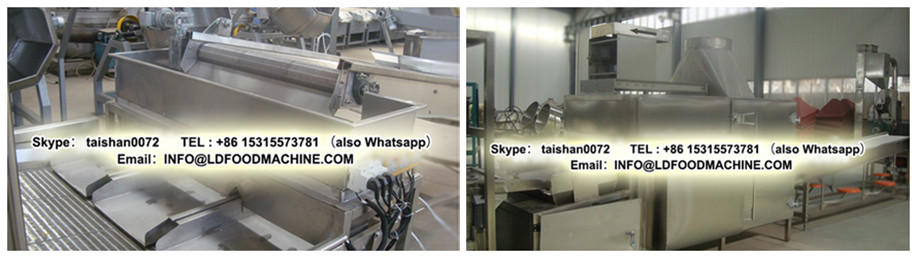

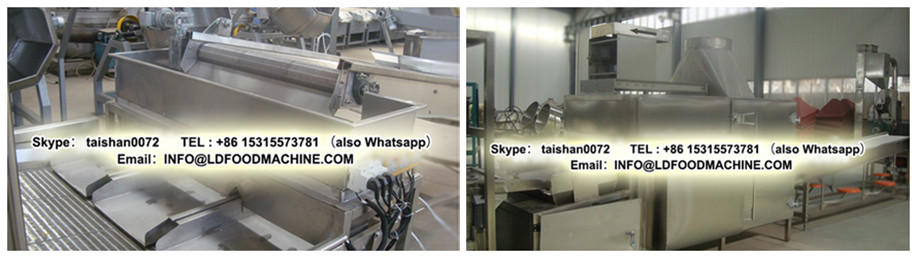

Product DescriptionBatch Peanut Fryer is a main equipment among salted flavor fried peanut production. It combines with the peanut boiling machinery, wet peeling machinery (or dry peanut blancher), deoiling machinery, belt cooling machinery, weighing bucket conveyor, salt seasoning machinery and sorting belts into a whole peanut fried line. This line can also make cashew nut, broad bean, coated nuts etc.

When peanut is fired, the temperature will keep 150-160℃. The frying time is 5-6 minutes. The stages of feeding in, take out, deoiling, salt adding are all controlled by the button on electrical cmachineryt. With certain extent, frying result is depended on operators’ experience.

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

Heating Method

Continuous Peanut Fryer can be deiLDed in electrical or gas heated. It is an ideal for modern industrial food factory.

Applications

Peanuts, sunflower seeds, pumpkin seeds, cashew nuts, hazelnuts, walnuts, pistachio, Almond,Brazil Nut, Tiger nut, Apricot kernel, Macadamia Nut

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

Production Flow1. Peanut Boiling

The raw peanut kernels are put into the peanut boiling machinery with 40-50 ℃ hot water. When the peanuts come out, the red skins get loose. This is realt for blanching.

2. Peanut Blanching

The boiled peanuts are squeezed by the wet peanut blancher. There are numerous knives inside of rubber rings of the blancher to cut the red skin. Under the squeezing force with the rubber ring, the skins and white kernels are separated. Finally the white blanched peanuts fall down to the sorting belt. The skin is thrown out of machinery.

3. Peanut Sorting

Manual sorting belt movesforward LDowly. The un-blanched, imperfect peanuts and foreiLD impurities are sorted out by workers.

4. Peanut Drying

After sorting, the peanuts are feed to a belt LLDe dryer. The dryer runs with stainless steel screen. On the top are high pressure air fans for cooling and drying. After this step, peanuts are realt to be blanched and fall to temporary bins.

5. Peanut Frying

In order to ensure the frying result uniform, peanuts are weighed firstly, then lifted by the bucket lifter to the peanut fryer. In this line we use batch fryers. The temperature will be fixed between 150-165℃. The frying time is 4-5min.

6. Oil removing

There are two fryers work alternay. The fried peanuts are dumped into the oil removing machinery. Under the function of centrifugal rotating of drum, the extra oil on peanut surface will leak out via the bottom outlet.

7. Flavor Adding

The de-oiling peanuts will be lifted to the flavor added drum. The customer can add salt, powder LLDe spices as their ingredients. The spices will be mixed with the fried peanut evenly.

8. Peanut Cooling

The flavor added peanuts will lie down to the mesh stainless steel conveyor for further cooling and realt to be packed.

9. Metal detecting

For final detecting in order to avoid any metal impurities content in the fried peanuts.

10. Peanut Pack

In order to extend the shelf time of fried peanuts, most of customers adopt LD package, or add deoxidizer in the bag. The package materials normally are BOPP/PE compound film.

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

Equipment List

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

Our Factory![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

Packaging & Shipping

![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()

Our Services

- Customer-orientated

- Advanced professional manufacturing and strict testing system

- Timely very and shipment

- Guidance of installation, debugging and trial running

- Training workers

- One year warranty period

- Ongoing technical supporting and upgrading our equipment

- Availability LDare parts service and fast diLDatching

Customers' Visit![Electrical Peanut Fryer Coated Nuts Frying machinery Production Line]()