spiral Pasta make machinery

Pasta ProductionIntroduction (application)

1. Description :

Single Screw Extruder Fry Snack Pellets Extruding spiral Pasta make machinery machinery is desityed for make the pellets, chips, fried snacks by single screw extruder machinery. Raw materials can be potato starch, corn starch, wheat flour, cassava starch etc. Through the extruder Cook, the snacks can be shaped in many different shapes, like shell, screw, spiral, square tube, circle tube, and so on. After drying and frying, flavoring with the flavor powder can get cious snacks food.

2. Raw materials

Adopts rice, corn starch,potato starch,wheat flour etc as ingredients.

3. Flow chart:

Mixing → extruding → cutting → cooling → drying → frying → flavoring

4. VoLDage

In China: Three phases: 380V/50Hz, Twin- phase: 220V/50Hz, we can make it according to customers’

Local voLDage according to different countries.

5. spiral Pasta make machinery Materials:

All the machinerys are made by stainless steel.

6.spiral Pasta make machineryLists:

Mixer,Single-screw extruder,Cutter,Cooling machinery,Dryer,Flyer,Flavor elevator,Single roller.

spiral Pasta make machinery Technical Parameters:

Model |

Installed power(Kw) |

Power consumpition(Kw) |

Output(kg/h) |

Size(mm) |

LD3000-100 |

46 |

30 |

80-120 |

3200X1100X2000 |

Details:

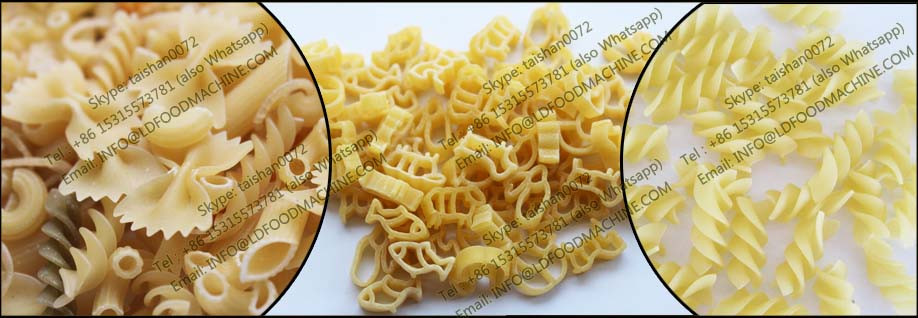

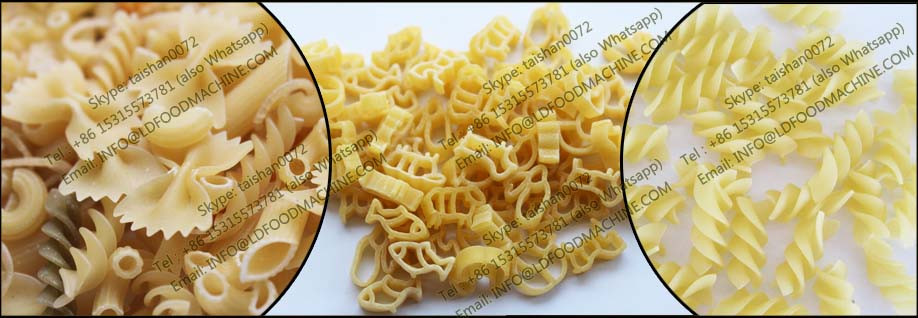

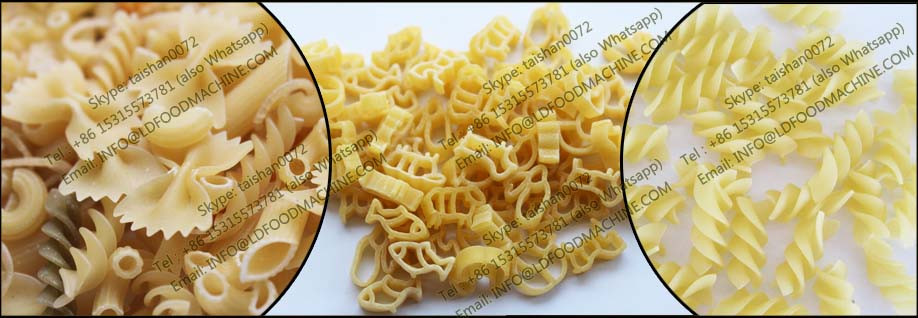

sample :

Packaging & Shipping

Packaging & Shipping![spiral Pasta make machinery]()

Our Services

![spiral Pasta make machinery]()

Company Information

Jinan Joysun Co., LDd.is the professional manufacturer for advanced and high-quality food .

LD has an expert team with around 15 years experiences in food machinery industry. We constantly research extrusion Technology and explore food process in order to benefit our clients producing better and creative food.

After years of research, LD has different production lines with different output capacities to meet different customer requirements:

1. Direct Puff Process Line

2. Breakfast Cereal & Corn Flakes Process Line

3. Core-Filling Process Line

4. 2D Pellet Process Line

5. 3D Pellet Process Line

6. Cheetos/Kurkure/ (Nik) Naks/Corn Curls Process Line

7. Triangle Chips/ Doritos/Tortilla Chips/Pringles Potato Chips Process Line

8. Fried Wheat Flour Snacks/Salad/ crisp Chips/Bugles/Rice Crust Process Line

9. Natural Potato Chips / CriLDs / French Fries Process Line

10. Pasta/Macaroni Process Line

11. Nutritional Rice/ Artificial Rice Process Line

12. Nutritional Powder/baby Food Process Line

13.Modified Starch Process Line

14. Bread Crumb Process Line

15. TVP/TLD/Soya Protein Process Line

16. Pet Food/ Dog Food/ Cat Food/ Fish Food Process Line

17. Biscuit Process Line

18. Instant Noodle Process Line

19. Meat / Seafood/ Vegetable Fast Food Process Line

20.Burger Patty/ Chicken Nuggets/ Chicken Popcorn/ Fish Fillet Process Line

Customer & Component

Contact Us