Nutrition Twin Screw Extruder Textured Soya Chunks Production Line

A.Our gas/steam powdered vegetarian food make uses the LD production equipment which is researched and developed according to the market demand and country's basic condition and basing on the advanced double-screw extruder techinques. The Enerable consumption can be reduced 50% by using the new Enerable.

B. Our cost saving protein food extruder / processing linehas the following features such as oil-absorbing, water-absorbing, ador-absorbing and can be used in all kinds of professions .The peanut and the tissue protein are a creation both here and LDroad which have the following features:fine tissue,clear fiber,without the raw soybean taste.Which is Healthy and take.

machinerys involved

1. Flour Mixer

To mix defeated soyLDean powder with water

2.spiral hoister

to Send the raw material to the extruder

3. Twin screw Extruder Auto Protein meat pricessing line

To cook the soyLDean powderl and extrude in different shapes.

3. Air conveyor

To take the extruded snack into oven or drying

4. Three layer Oven

To dry snacks

Parameters

Model |

Input VoLDage |

Installed Capacity |

Power Consumption |

Output |

Size |

LDS65-II |

380v/50Hz |

80kw |

55kw |

180-220kg/h |

1600x1200x2100mm |

LDS85-II |

380v/50Hz |

125kw |

100kw |

300-500kg/h |

1900x1200x2300mm |

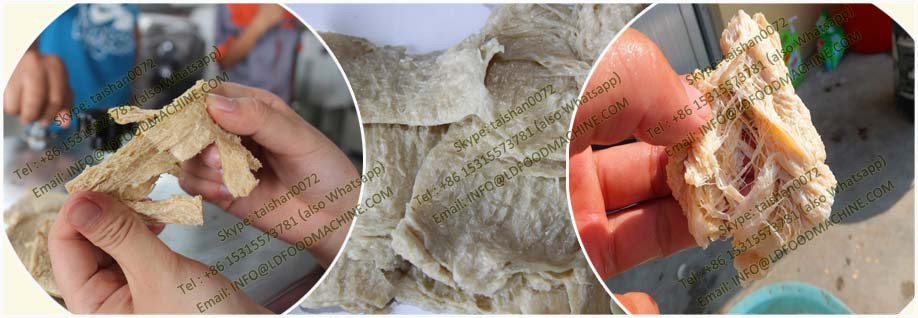

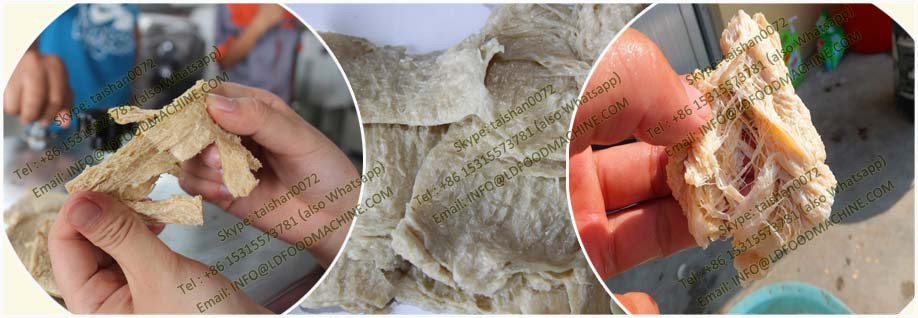

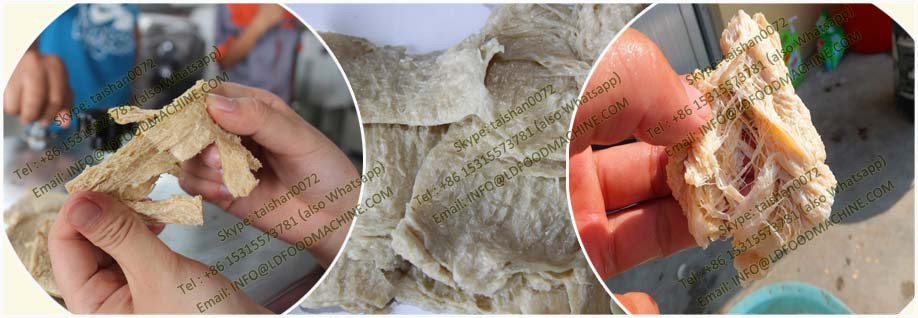

Finished Products

Added more nutrional elements in the protein food production line, through mixing extruding,cutting ,drying and flavouring, the textured soya meat can be produced, take as the meat and Healthy as the vegetables, very popular with customers.

Company&Equipment

With a warehouse of 2000 square meters, we have enough food make extruder and production equipments store, your are always welcome to visit us for the textured protein food machinery test running.

Packaing & Shipping

The food machinerys are seperated before shipping, the food make equipments are packed with film and wooden cases, to avoid the possible damage of the protein food make machinery during shipping, all food machinery parts are supported and fixed by wooden and carton bricks inside the case

![Nutrition Twin Screw Extruder Textured Soya Chunks Production Line]()

Customers Visit

In the food industry, reputation is our life, customers are our prioriLD, we maintained high reputaton both inside and outside China, after visiting our food machinery plant, most of our customers would like to estLDlish long term business relationship with us.

Service & Turnkey Solution

a.) consultation service before, during, and after sales;

b.) Project plng and desity service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from

seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.