Product Description

2017 hot model factory price automatic short pasta macaroni make machinery![2017 Model Factory Price Automatic Pasta Macaroni Producing machinery]()

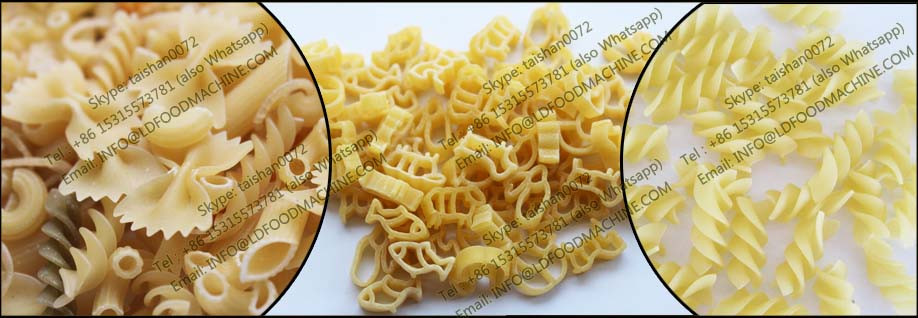

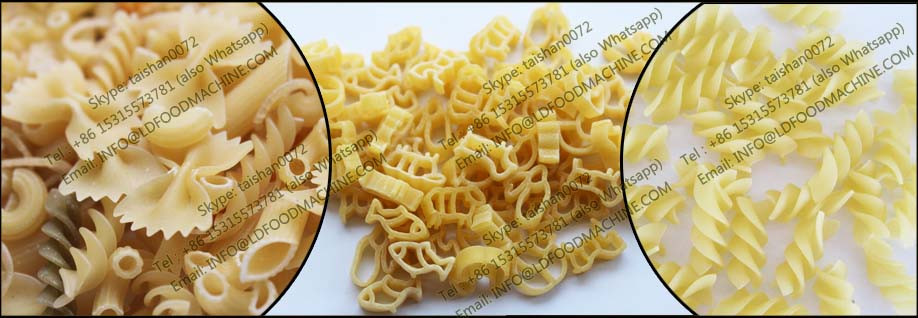

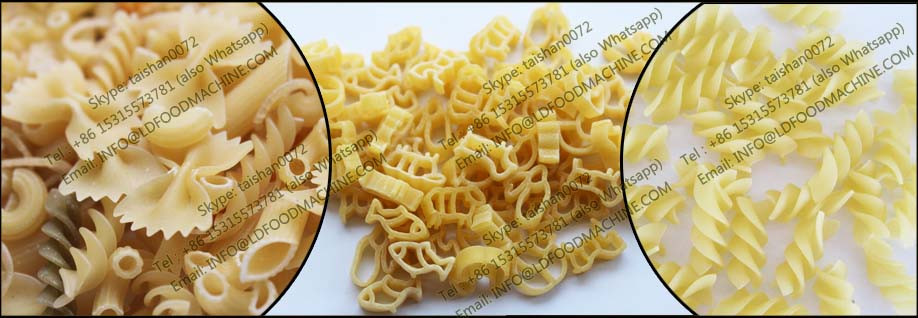

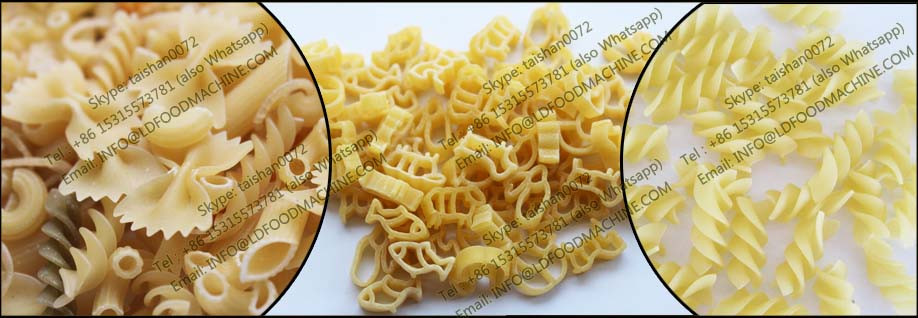

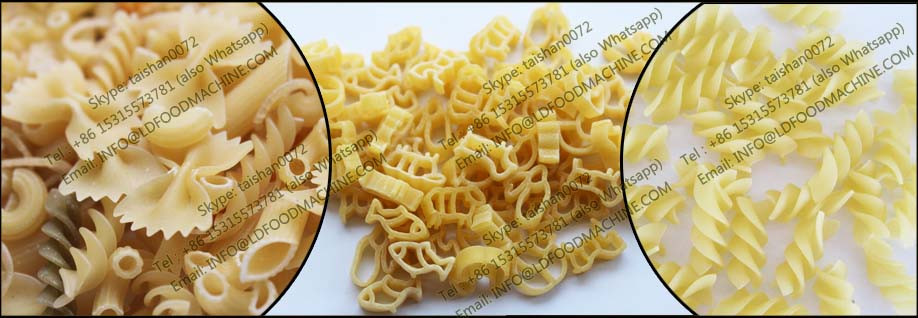

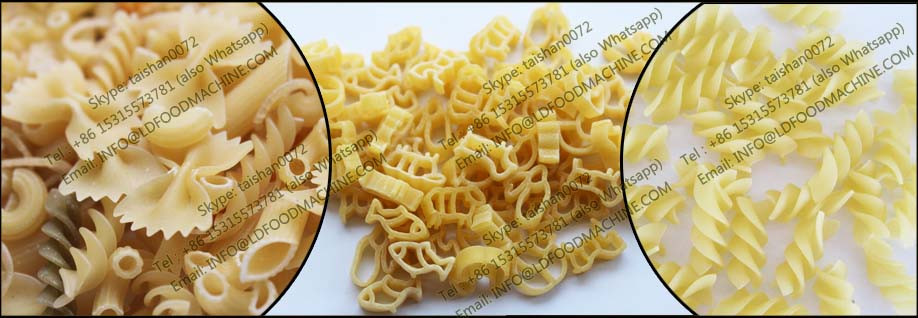

This macaroni production line is with reasonable desity and with high automation. The screw is made by 38 CrMoAl, with self-cleaning function, high strength and long service time. With moulds changing, customers can produce different shapes of pasta, macaroni.

Technical Parameter

| Parameters |

SX3000-100 |

SX3000-130 |

| Input VoLDage |

380V/ 50Hz |

380V/ 50Hz |

| installed Capacity |

105kw |

125kw |

| Power Consumption |

85kw |

100kw |

| Output |

80-120kg/h |

150-220kg/h |

| Length |

26m |

30m |

Brief Introduction of corn flakes processing line

No |

Name |

Brief introduction |

1 |

Raw material |

Corn, rice, wheat, oat, barley powder |

2 |

Basic Recipe |

Grist powder; sugar; coco; cheese; water |

2 |

Processing flow |

Mixing system; Extrusion system; flake system; Drying system; Flavoring system; Drying system;packsystem |

3 |

Equipment involved |

Mixer; Screw elevator; Single screw extruder; Vibrator; Air conveyor; multi-layer cooling conveyor; Recycling dryer |

4 |

Final products |

Variety shapes are available for ball, tube, stick, ring,

fruit loop, star, wheel and flower and heart shape by

adjusting the mould in the extruder ; macaroni

|

5 |

machinery material |

Stainless steel 304 or as customer’s request |

Simple Sample

![2017 Model Factory Price Automatic Pasta Macaroni Producing machinery]()

Packaging & Shipping1. Testing machinery before package

2. Package:

The machinerys will be wrapped by plastic film or packed into wooden cases. Firstly,

anti-rust oil painted to the machinery, then wrapping film and air bubble pad then export

non-fumigation wooden casespackoutside.

Containers will be sent to our factory to load the machinerys and will be sealed before

being sent out to make sure the safety of our machinerys.

Or any other ones agreed between buyer and seller

Company Information

Our factory has over 22 years experience of the industry development. We have well-experienced managers,outstanding engineers as well as well-trained technical workers. By constant technical exchange with well known firms of the same line in the worldand also by introduction of advanced techniques and experiences into our company,we have established a strong technical guarantee system.According to the clients' different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet food and so on. Our technical assistance will help clients produce high quality products all the time. Depending on our rich experience and professional experts on the extruded food industry, we could offer the most suitable and complete program to assure that your investment will get biggest profit.

![2017 Model Factory Price Automatic Pasta Macaroni Producing machinery]()

![2017 Model Factory Price Automatic Pasta Macaroni Producing machinery]()

Our main processing lines

No |

Product Line |

1 |

Popcorn machinery |

2 |

Pet Food Processing Line |

3 |

Macaroni Processing Line |

4 |

Fried Pasta Processing Line |

5 |

3D Processing Line |

6 |

Modified Starch Processing Line |

7 |

Nutritional Rice Processing Line |

8 |

Soybean Protein Food Processing Line |

9 |

Automatic Instant Noodle Processing Line |

10 |

Extrusion Fried Pellet Snacks Processing Line |

11 |

Corn Flakes/ Breakfast Cereals Processing Line |

12 |

Extrusion Baked Puffed Snacks Processing Line |

Contact

Please feel free to contact us if you are interested in any of our products. We sincerely hope to cooperate with clients from all over the world.

Have a good day.

![2017 Model Factory Price Automatic Pasta Macaroni Producing machinery]()