Italian pasta/LDaghetti pasta macaroni food make machinery

1). Description:

multi-functional commercial pasta make machinerys also known as the shells Crispymachinery, hemp food machinerys, etc.) is by the majority of users food processing .

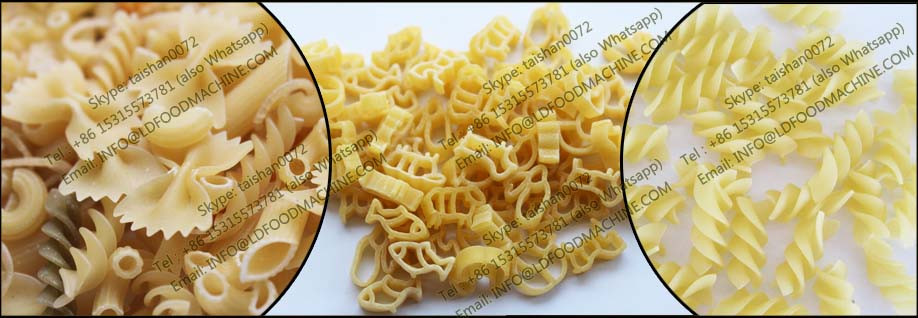

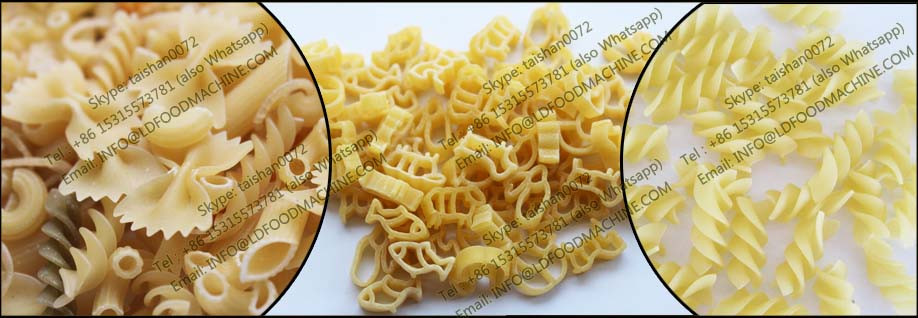

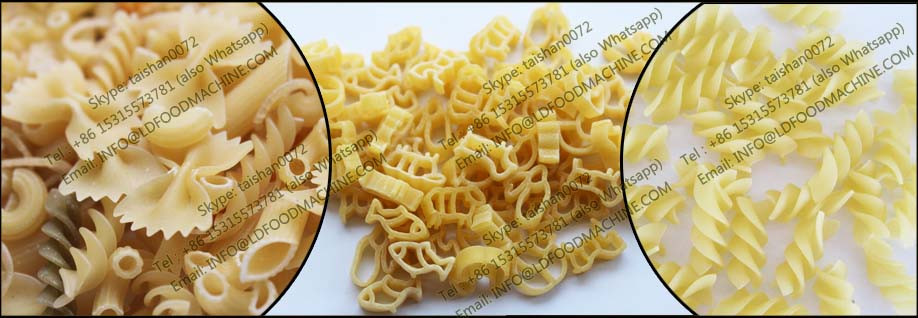

2.This commercial pasta make machinerys use flour (can also use rice flour, starch, cereals, etc.) as raw materials, through different mold, can produce a Variety of pattern LLDes of s, such as: shells criLD, Orecchiette, the Tremella criLD, five-star criLD, rice crust, lanterns , conch, peanut LLDe, big and small empaint tubes of different shapes, cious and take food series; at the same time, it can produce hollow noodle, screw noodle, macaroni , white fungus , stretched , vegetables and other pasta.

3.This commercial pasta make machinerys is ideal equipment for investors new to win business opportunities.

Performance characteristics of commercial pasta make machinerys:

1. Compact structure, convenient operation, low power consumption and high yield

2. Adopt the simulation of forming Technology, and automatic molding cutting

3. Wide range, Variety of tricks.

2). Raw materials:

adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

3). Products:

This line can be used to produce pellets, snacks, corn flakes by adjusting the models from extruder;

4). Capacity: 100-120kg/h

5). Flow chart:

Mixing system---Extrusion system----Cutting system---Drying system---Frying system---Flavoring System --Pack system

6). VoLDagein China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it

according to customers’ Local voLDage according to different countries

7). machinerys materials:

All the machinerys are made by stainless steel

8). Technical parameters

Model |

Installed power |

Real power |

Output |

Dimension |

LD-65 |

100kw |

70kw |

100-kg/h |

27000x2000x2000mm |

Our Services

a.) consultation service before, during, and after sales;

b.) Project plng and desity service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

Packaging & Shipping

![Italian pasta/LDaghetti pasta macaroni food make machinery]()

customers with

![Italian pasta/LDaghetti pasta macaroni food make machinery]()

company Information

we LD &equipment CO.,LDD is a manufactory professional do the corn flakes processing line ,we have good engineer ,have many years installation experience ,can help our customer do the good quality product

If you want to know more ,please feel free to send me inquiry and i will send video,pictures to you LDout our Macaroni Pasta make machinerys .

.