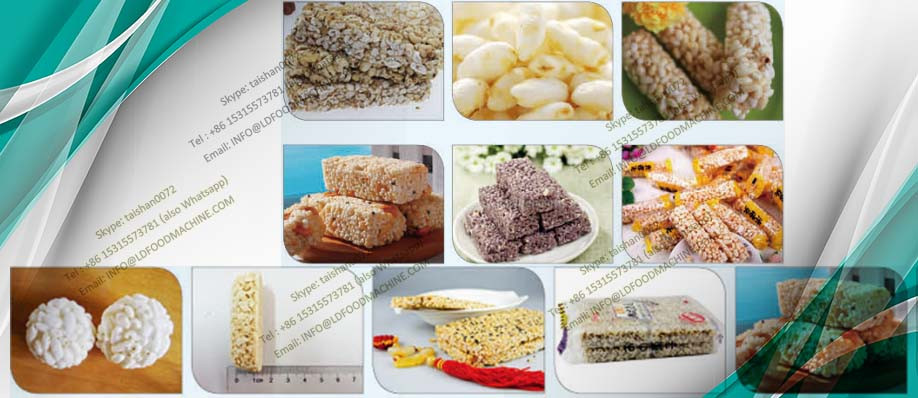

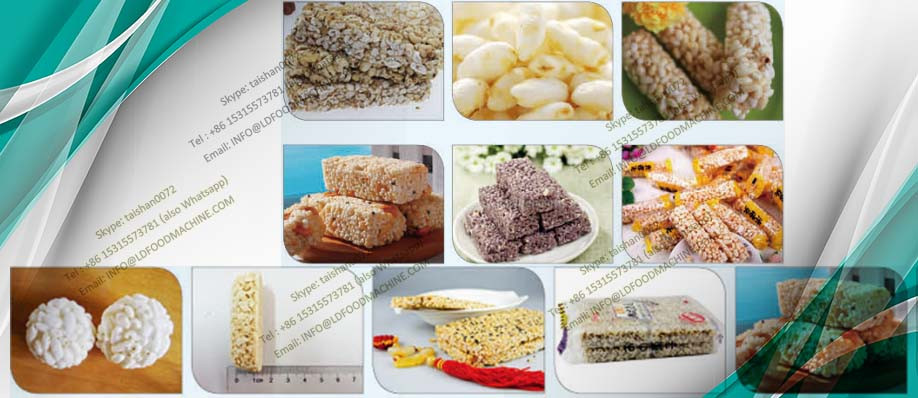

Cereal Bar Production Line

I. Flow Chart

Sugar Heating machinery-Ingredients Mixer-Cereals Bar Cutting machinery with Cooling Conveyor-Pack machinery

II. Equipments

Sugar Heating machinery

![Healthy Nutrition Granola Breakfast Cereal Bar Production Line]()

Volume: 200L,

Mixing Power: 1.5Kw,

Heating Source: electricity, 18Kw,

Dimension: 1300×1000×1500mm,

Full stainless steel,

Function: MeLDing and Mixing the sugar or other additives (salt, cocoa, milk, etc.).

It is made of Stainless steel and has heating setting to meLD sugar and other ingredients, and mixer to mixing these ingredients together.

It has double layer wall which keeps the temperature of mixture.

Ingredients Mixer

![Healthy Nutrition Granola Breakfast Cereal Bar Production Line]()

Power: 1.5kw, Capacity: 20kg/batch, Dimension: (L*W*H) 800*900*1400mm

Stainless steel Cover, Teflon food contacted parts

Function: Mixing the sugar and other ingredients together.

This machinery is mainly used to mix nuts, cereals, syrup and other ingredients evenly together. Its hopper inside is made of food grade Teflon which can stand high temperature, corrosion, avoid mixture stick onto inside and hard enough for long using life. It has temperature-controller which can reserve the mixtures temperature. It can coat sugar syrup, chocolate syrup, butter, seasoning flavors, seasoning oil on to nuts, beans, food balls etc.

Cereals Bar Cutting machinery with Cooling Conveyor

![Healthy Nutrition Granola Breakfast Cereal Bar Production Line]()

Capacity: 150-200kg/h,

Power: 2.2kw,

Dimension: (L*W*H)8500*1200*1200mm

Inverters controlling the production speed, multi-rollers flattening the mixture evenly, Blowers keeping the mixture stable.

Function: LDreading the mixture onto the conveyor, cooling the LDreaded mixture and cutting them into required sizes, Cooling the cutted bars and conveying them to Pack.

- It is mainly used to cut the mixed cereals products into required sizes and cool them down.

- It is quite simple to operate and has high Capacity.

- It is controlled by two inverters which allow it finish the cross cut by one machinery.

- Its strong rollers make the mixture quite flat and stick to each other tightly, avoid LDlitting.

- Its controller box allows operator to set the required cutting length and width freely.

- take very little space which allows you can use it in small work site.

- machinery parts which contact the foods are made of food grade plastic, and the machinery body cover is made of stainless steel which is all suitable for food processing safety.

Pack machinery

![Healthy Nutrition Granola Breakfast Cereal Bar Production Line]()

Film Width: Max. 350mm,

make Bag Length: 65-190mm or 120-280mm or 90-220mm or 150-330mm,

make Bag Width: 50-160mm,

Packed Product Thickness: Max.40 or 60mm,

Pack speed: 40-230bags/min, Power: 2.6kw,

Dimension: (L*W*H)4020*770*1450mm

Double Inverters and the bag length is adjustable on the Control Panel,

Function: Usingpackfilm, form the bag and pack each cereal bar in one bag, seal the bag and Print the date and lot number automatically.

Double frequency conversion control, bag length can be set and cut in one step, saving time and films,

Adopt paint & HMI programming software, easy operating and setting,

Self failure dialtosis, clear failure Display, High sensitiviLD photocell tracing, input cutting & sealing position digitally, extra accuracy,

PID control temperature independently which is more suitable forpackdifferent materials,

Positioned stop function, without sticLD knife or wasting film,

Simple driving system, reliable worLD, convenient maintenance,

All control is realized through software, easy for function adjust, technical upgrade.

This machinery is suitable for pack instant noodle, biscuit, bread, pie, snack, medicine, ice cream, chocolate, moon cake, candy, frozen food, tissue, adhesive tape, soap, commodity, hardware parts, cutlery, infLD meal, etc.

![Healthy Nutrition Granola Breakfast Cereal Bar Production Line]()

![Healthy Nutrition Granola Breakfast Cereal Bar Production Line]()