Specifications

1.CE & ISO 9001:2008 certified2.twin-dehullers design

3.equipped with frequency inverter

4.patented product

SUNFLOWER SEEDS SHELLING MACHINE TFKH1200

FUNCTIONS AND FEATURES

sunflowe r seeds dehulling & separating equipment Model TFKH1200 is our latest generation product designed by Qiaopai company, made on the basis of improvement of previous sunflower seeds dehulling&separating equipment model TFKH1000, with twin-dehullers exclusive design,the application of frequency technique realises the well control of the dehullers. The design of pneumatic device for back-flowing materials, let the un-dehulled sunflower inshell flow back to dehullers automatically, make the dehulling works more efficient.

The whole equipment can pre-clean, dehull, remove sunflower shells,separate and reseparate your product at one time, it's the optimum equipment for your sunflower kernels processing industry. It features high persentage of dehulling rate, low persentage of brokens, high automation degree and easy maintenance.

COMPONENT

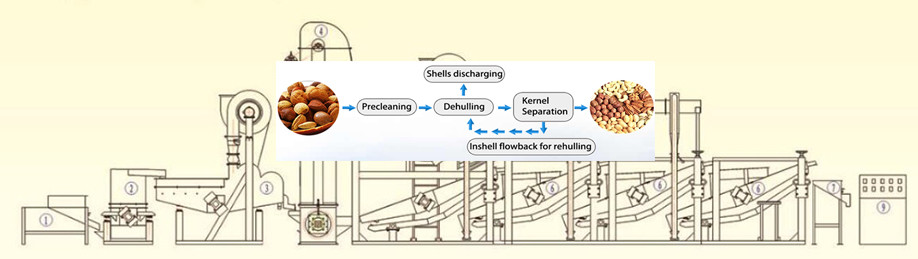

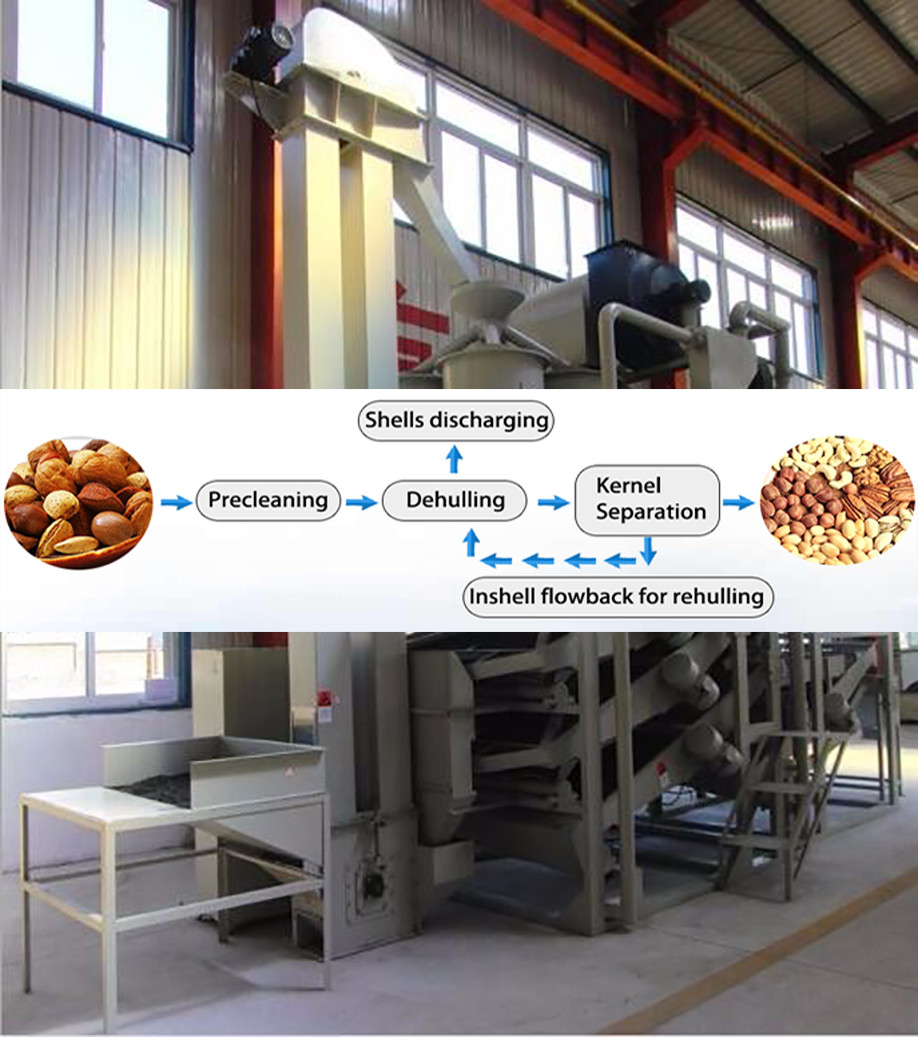

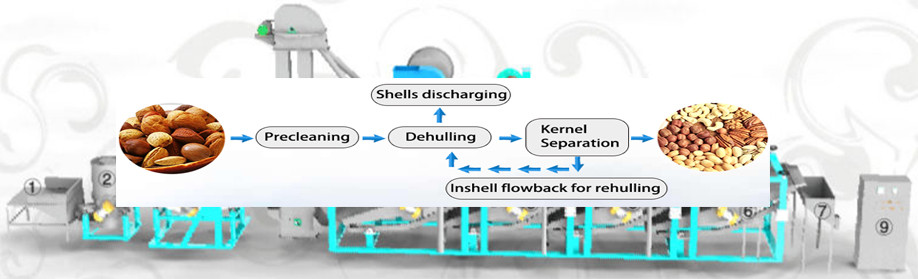

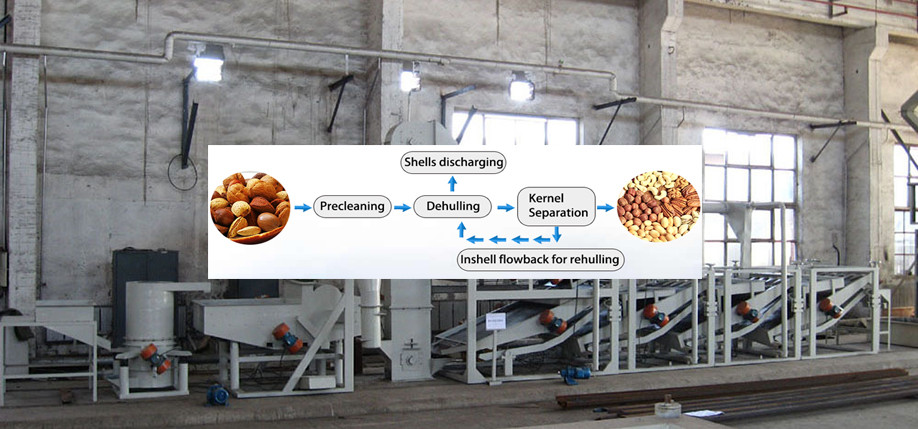

It consists of input hopper 1, spiral elevator 2, multi-functional cleaner 3,bucket elevator 4, twin-dehullers 5, reseparator 6 (3sets), kernels collector 7, pneumatic device for back-flowing materials 8, electric control cabinet 9.

PROCESS

TECHNICAL PARAMETERS

Power |

14.59kw(380v 3phase 50Hz) |

Input capacity |

500-800kgs/hour(varies with raw materials) |

% of whole kernels |

90% minimum (kernels less than 1/2 whole kernels are brokens) |

% of inshell in final kernels |

2-5% adjustable |

Space occupied |

14.4m*2.8m |