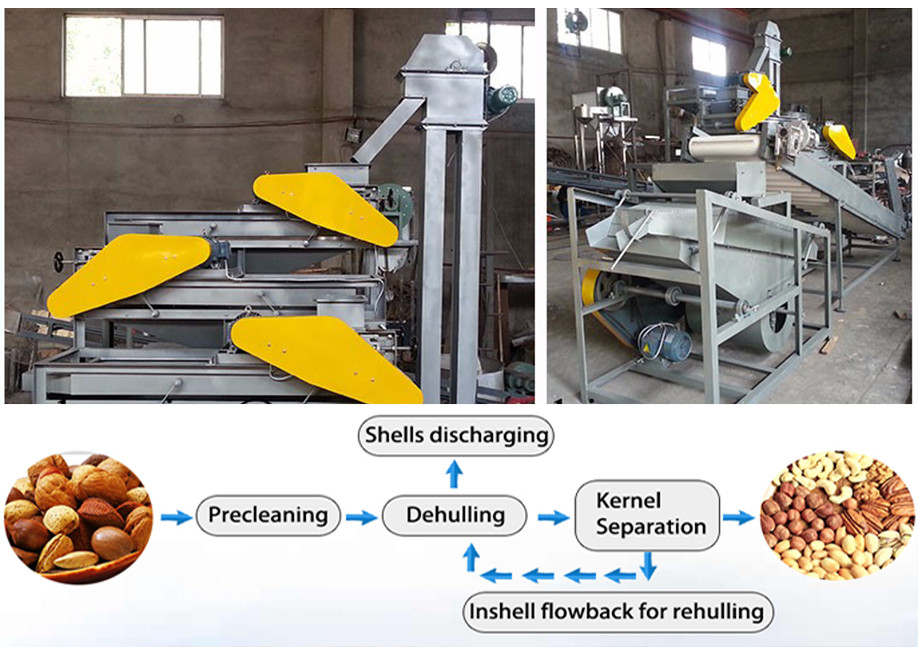

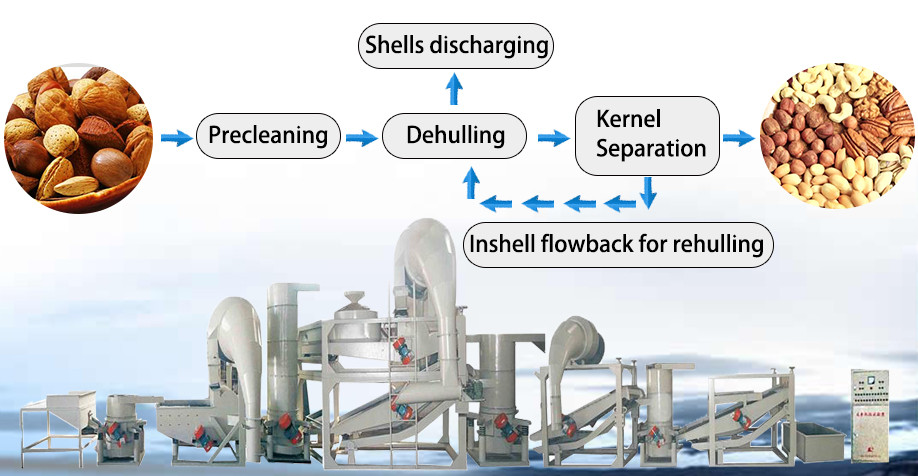

The equipment can pre-clean sunflower seeds, then dehull seeds, remove shells, separate and re-separate un-hulled seeds, return back un-hulled seeds to dehuller for re-hulling again automatically, thus automation degree has been greatly improved. It's the most ideal equipment to process sunflower seeds in the worldwide. For more info, pls feel free to contact me. thanks.

Main parameters of TFKH1500

Power: 16.23kw (380v/220v 3p)

Input capacity:0.8-1.0t/h

% of the whole kernel: 95% min.

% of un-hulled seed in the kernels: 2% max.

Dimension: 14.4m × 2.8m, Height: 4.3m

Weight: 7t

Operator: 2persons

Main parameters of TFKH1200

Power: 13.59Kw (380V/22v 3p)

Input capacity: 0.6-0.8t/h

%of the whole kernel: 95% min.

% of un-hulled seed in the kernels: 2% max.

Occupied area: 14.4m × 2.8m

Height: 4.3m

Operator: 2 persons

The equipments are widely used in China, Europe, Africa and South America, etc.

Meantime, we also specialize in cleaning, dehulling & separating machines and equipments for pumpkin seeds, watermelon seeds, oats, Inchi Nut, job’s tears, linseeds (flaxseed), Perilla seed, almond, hazelnut, mung bean (green bean), Buckwheat, bitter buckwheat, foxnut, Jatropha seed, acorn, peach inshell, etc. in China.