Pumpkin Seeds Sheller/dehulling machine BGZ300

[Functions and Features]

Pumpkin seeds dehulling & separating equipment Model BGZ300 is a patented product of our company and is the independent intellectual property of Qiaopai company. It contains 3 national patents. This equipment can dehull pumpkin seeds, remove shells, separate un-hulled seeds from kernels.

It features as following:

·it adopts wet method for dehulling process

·make it more efficient on dehulling rate and lower broken rate through improvement on existing dehullers

·it adopts recycled dehulling process, that is to say the unhulled seeds will go back for recycled dehulling automatically.

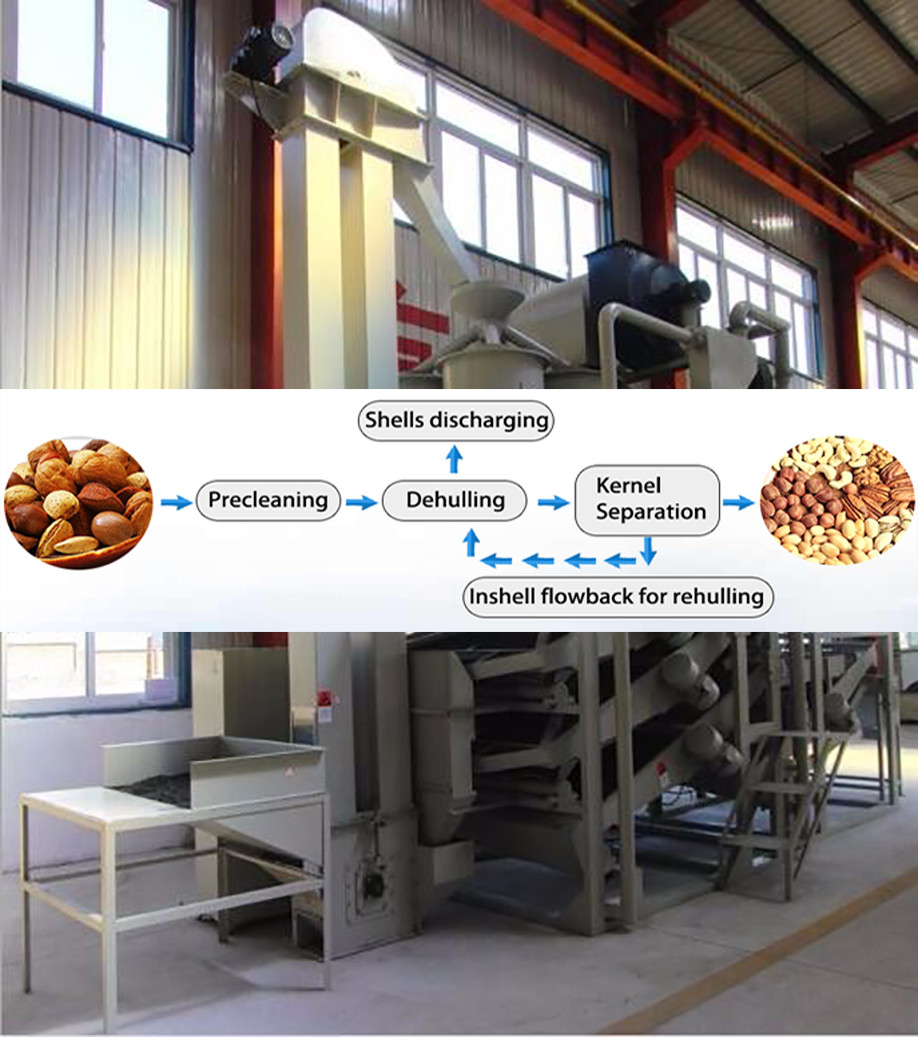

·It adopts negative-pressure method to suck the shells out instead of blowout to reduce the dust quantity.

·Increase the distance and area of the separation screening, make seed-kernel separation works more thoroughly,

thus reduce the persentage of broken due to more kernels going back to dehullers for redehulling.

·The screening section is changeable as per the individual size of the pumpkin seeds

·Compact design, low loss of materials and easy maintenance.

Screen mesh made from punching works of

Improved-design of dehullers make the dehulling premium quality cold rolled sheet,durable service.

process more efficient. Prevent mesh from blockage due to the bouncing

ball design.

Adopt the vibrating and negative-

pressure separation works and spiral Vibration source of the

Wider&longer screening design discharging for shells-discharge to equipment adopts vibratory

make the seed-kernels make the shells collecting works motors design, features easy

separation works more easier and meanwhile reduce the and quick installation, no

efficient. dust accumulation greatly during foundation works requires

process.

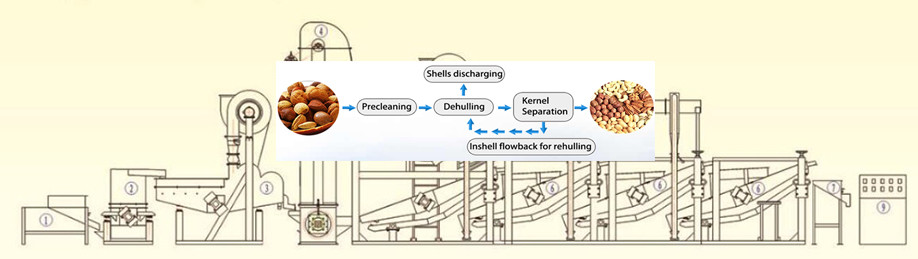

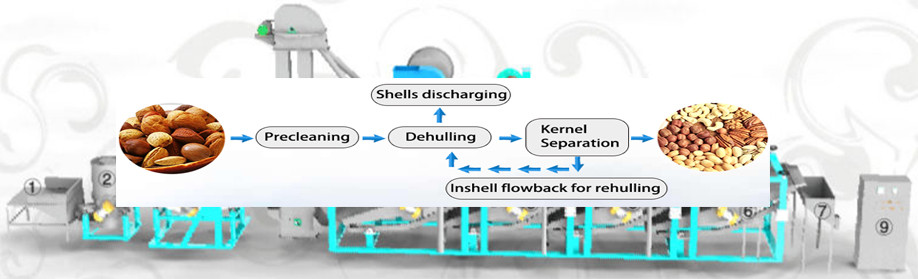

[Component]

It consists of input hopper (1), bucket elevator (2), dehullers (3), electric control cabinet 4).

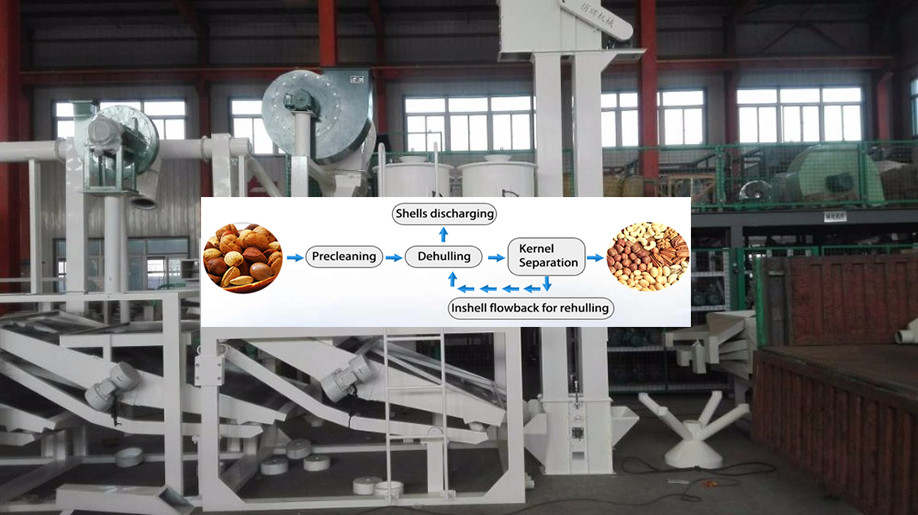

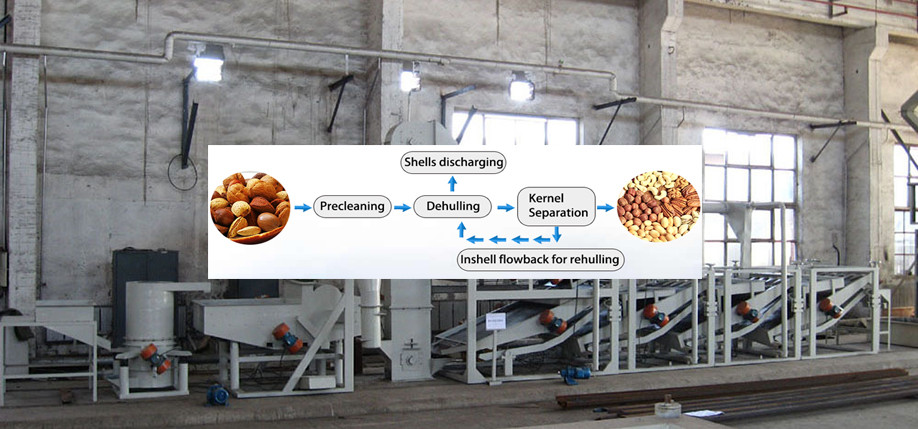

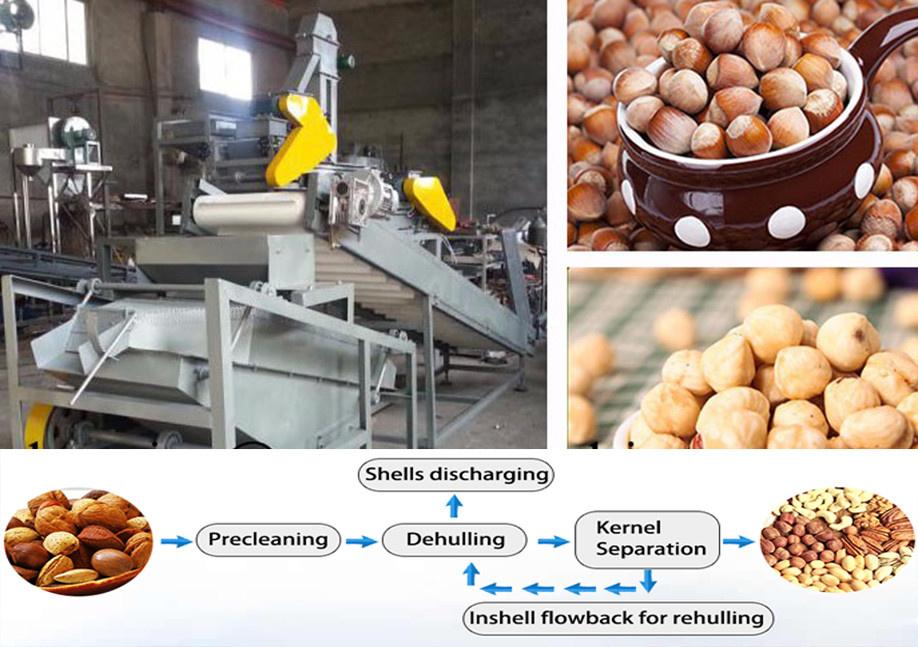

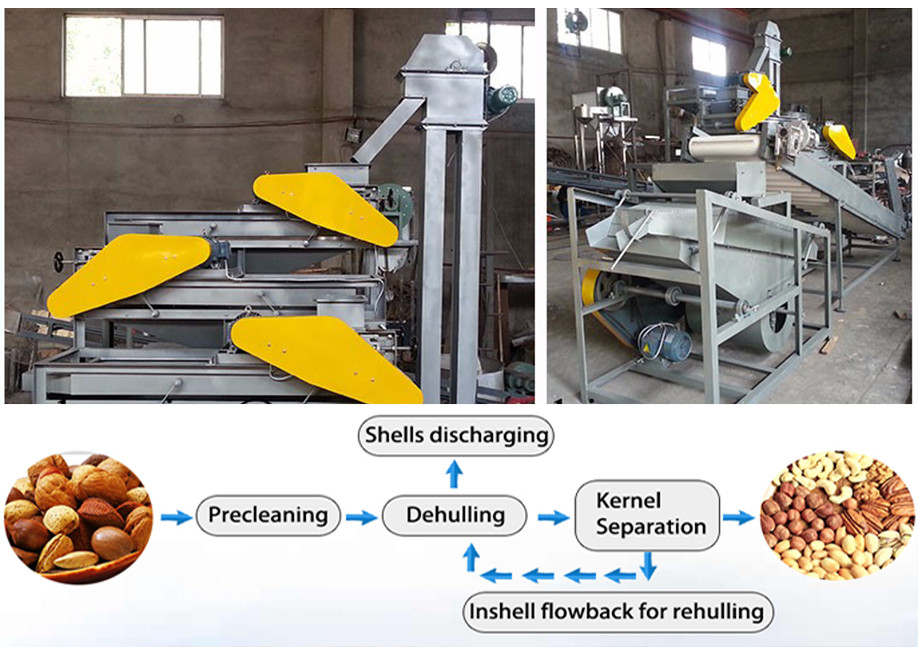

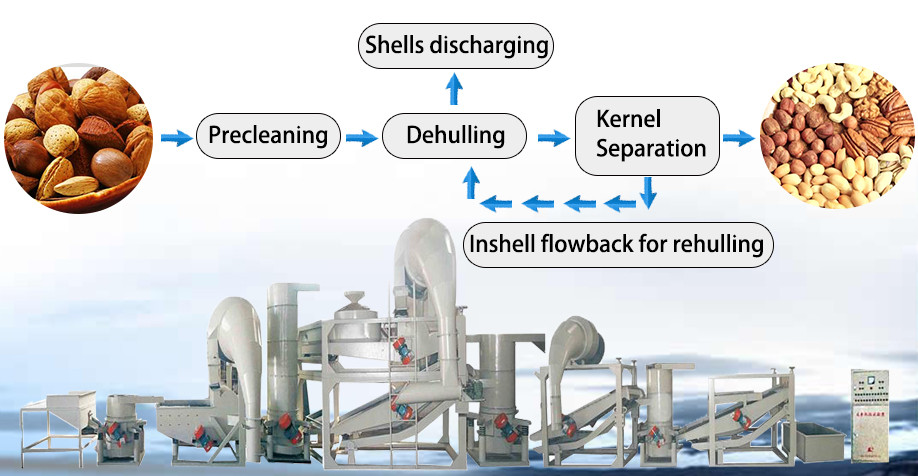

[ Process]

[Technical parameters]

Power: 8.19kw(380v)

% of whole kerenls:98% min. (kernels that are less than 1/2 whole kernels are brokens)

% of inshell in final kernels: 2% maximum

Input capacity: 200-300kgs/hour

Space occupied: 6.5m×2.9m

Height:3.5m

Weight:4.5mt