Specifications

1.CE & ISO 9001:2008 certified2.compact design

3.dehullers adjustable

4.patented product

JOB’S TEARS DEHULLING&SEPARATING EQUIPMENT TFYM400

FUNCTIONS AND FEATURES

Job’s tears dehulling and separating equipment is our company’s patented product with independent intellectual property. It’s an original technology, which can be used to size, dehull and separate your job’s tears, and meanwhile the un-hulled seeds will go back to dehullers for re-hulling automatically.

It features easy adjustment to the dehulling clearance of the dehullers, high production efficiency, and high percentage of whole kernels. Meantime, the mixtures of shells, seeds and kernels after dehulling, we adopt vibrating negative-pressure separator screening the shells out and spiral discharging for shells-discharge properly. All the key technologies have already applied for national invention patent and a patent for utility model. Furthermore the separating screen equipped with cleaning device of screen surface, it features easy operation, high degree of automation, safe and reliable, beautiful and durable and extensive application.

COMPONENT

Sizing unit: consists of input hopper, elevator, sizing machines (quantity of sizing machines depends on the raw materials, shown 5 sizes as per our drawing )

Dehulling & Separating unit: consists of input hopper, elevator, dehullers and electric control cabinet.

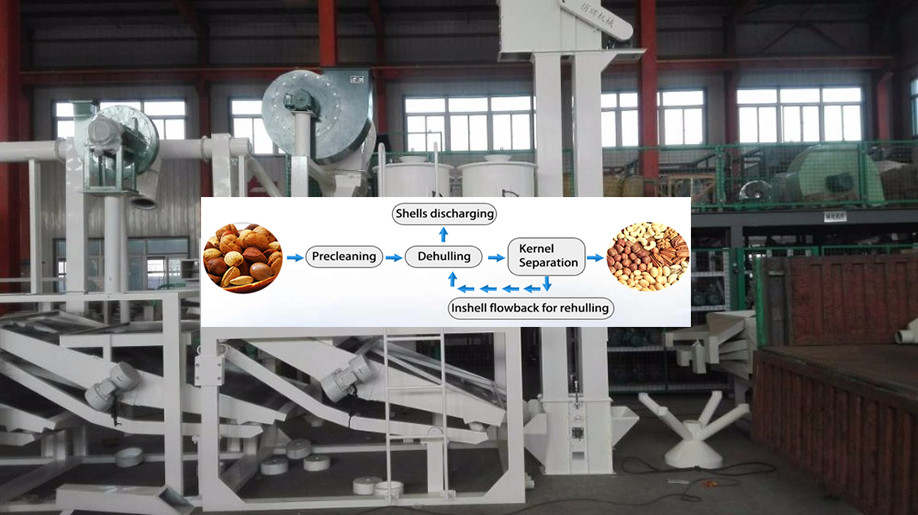

PROCESS

TECHNICAL PARAMETERS

Power |

12.47kw(380v 3phase 50Hz) |

Input capacity |

800-1000kgs/hour (sizing unit) |

300-400kgs/hour (dehulling unit) | |

% of seeds in final kernels |

1-2% maximum |

% of whole kernels |

98% minimum |

Space occupied |

15m*2.8m |

Height |

4.2m |

Weight |

10mts |