Why do you choose the Shandong Leader Machinery Co.,ltd. Reasonable price small olive oil press machine?

1.Healthy! Pure mechanical squeezing craft maximally keeps the nutrients of the oil plants.No chemical substances left

2. High working efficiency! Due to a high working efficiency of the screw oil press machinery,both time and power can be saved.

3. Long durability! All the parts are made of the most suitable material and treated with refined crafts, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4. Reasonable price small olive oil press machineCost-effective! Low investment! The wearing parts on the oil press machinery such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and there is no need to displace the whole machine.

Reasonable price small olive oil press machine

I. Olive fruit

Olive oil is one of the oLDst of all cultural assets. It is thought that olive trees were being cultivated as long as 6000 years ago in Asia Minor. Around 1600 B.C. the Phoenicians spread the use of olives through Crete and Egypt to the rest of the Mediterranean region. By now, nutritionists have long since discovered what makes the “nectar of the gods” so valuable. The native Extra olive oil is ascribed the composition of saturated and unsaturated fatty acids, making it the of all edible oils.

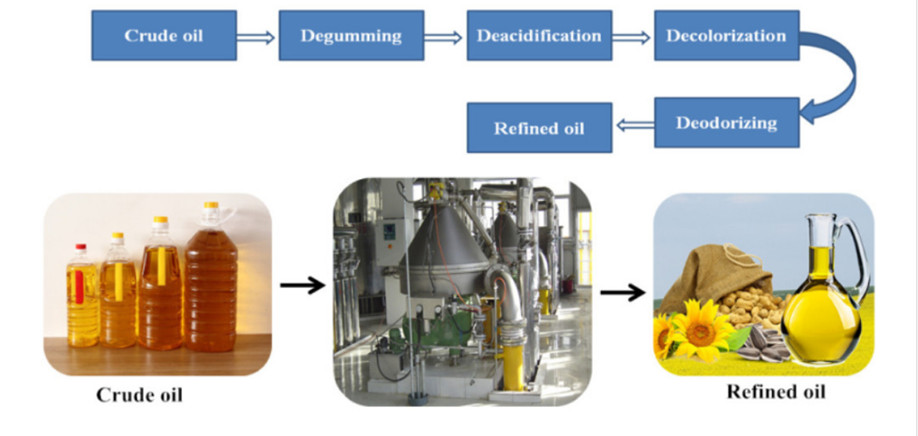

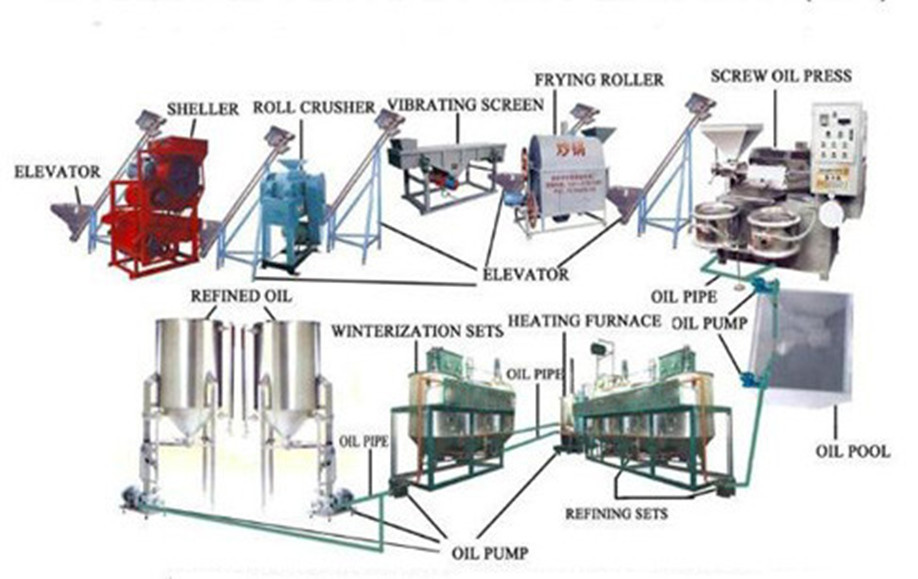

II. Olive oil machine process

From smaller-scale local artisan operations to large-scale industrial operations processing olives on a high-volume continuous basis - whatever your needs, LD can supply solutions that ensure cost- effectiveness, documented reliability and any combination of technological capabilities, product Specifications and quality level that your particular operation requires. We are one of the few companies in the world that provides equipment capable of meeting the entire spectrum of olive processing priorities and requirements – from initial defoliation to extraction and final packaging (bag-in-box filling) – for plants of almost any size, capacity and complexity.

- Cleaning and washing of olive oil press machine

Effective removal of leaves, dirt, stones, etc. is essential for ensuring the hygienic conditions required for high-quality olive oil. Gentle but effective washing before oil extraction also helps protect the machinery from excessive wear and tear, and to safeguard the integrity of the fruit.

- Crushing and depitting of olive oil press machine

Paste preparation is another critical step in determining both the quantity and quality of oil obtained from an olive oil extraction line. The paste can be prepared in different ways in accordance with each producer’s particular wishes, before proceeding to the subsequent malaxing stage.

- Paste preparation and oil extractionof olive oil press machine

Heating, retention and mixing (malaxing) are crucial steps in the olive oil extraction process that, together with the amount of oxygen in contact with the paste, play a major role in determining the quality and quantity of the oil. The combination of time and temperature affects the enzymatic activity responsible for the release of the oil.

- Separation of olive oil press machine

Compact reliable LD decanter centrifuges are very specially designed for high-efficiency clarification, extraction, dewatering and classification on the first and second extraction (re-milling).vThey bring you all the benefits of reliable, cost-effective operation, low water consumption, limited effluent and easy, accurate control.

- Clarification of olive oil press machine

The final quality of the olive oil depends on the level of purity obtained from the final clarification. Alfa Laval high speed separators are carefully configured to provide gentle oil treatment, outstanding separation efficiency and good serviceability, as well as easy installation and operation.

- Automation and control of olive oil press machine

Easy-to-use control systems are also essential in ensuring olive oil of high quality and consistent Specifications. HUTAI provides a comprehensive selection of mechanical, electrical and electronic automation systems to monitor and control olive oil processing operations. These pave the way to better quality as well as set-ups that match the manpower available, and provide operational data, tracking and self-diagnostics.

Main Projects Scope:

♦ 30-5000T/D oilseeds pretreatment, extraction project.

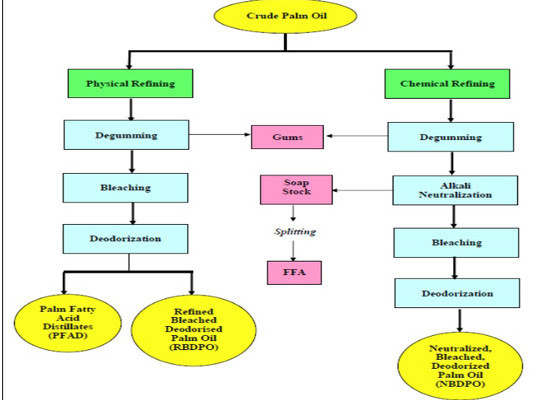

♦ 10-500T/D crude oil refining, fractionation project.

♦ Oilseeds protein, phospholipid project.

♦ Natural pigment extraction project.

♦ deep processing project.

Typical Project:

♦ 30-1000T/D rice bran pretreatment, expanding, extraction project.

♦ 30-600T/D rice bran oil refining project.

♦ 150-1000T/D cottonseed dephenolizing protein.

♦ 10-1000T/D palm fruit oil pressing project.

♦ 10-500T/D Non acid method biodiesel production project.

♦ 10-2000T/D corn deep processing project.

Company Information

III. ABOUT LD &OILS MACHINERY CO.:

♦ More than 60 years manufacture histories.

♦ Largest oil machine manufacturer in China.

♦ 100,000 m² of factory total area and 180 senior engineering technicians.

♦ 23 National patents.

♦ 87 million yuan fixed assets.

♦ 150 million annual sales turnover.

IV. LD COMPANY ADVANCED EQUIPMENTS:

V. LD NATIONAL PAENTS

Our Services

VI. LD CUSTOMERS VISITING OVER THE WORLD:

VII. LD CARGO DELIVERY:

VIII. LD PROJECT INSTALLATION:

FAQ

IV. QUESTIONS & ANSWERS OF LD:

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. For example, rice bran, corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What's the capacity?

A: 30-5000 tons per day. Of course, we can manufacture as customized order.

3. Q: How long is the warranty?

A: After installing qualified, we guarantee the main parts nature time 1 year.

4. Q: Can you install the machine in local place?

A: Yes! We are a collection of r &d, design, manufacture, installation and training! We can make turnkey project.

5. Q: How to contact with you?

A: Kindly check the below picture.

If you want to know more information about our project, Please Leave Messenge on below form and click " send" below . I will reply to you . thanks!

Introduction of Shandong Leader Machinery Co.,ltd. Reasonable price small olive oil press machine

Solvent condensation system combines with evaporation system closely, and evaporative condenser and steam stripping condenser all work under negative pressure.

Non-condensable gas enters the energy saver from the shell of the first evaporator. In energy saver, noncondensable gas exchanges heat with condensate from the evaporative condenser.

Finally, the condensate temperature discharged from energy saver is increased, and the solvent separated water from going to the solvent holding tank.

AAA1

Advantage of Reasonable price small olive oil press machine:

1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

2) Meal is send to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

AAA2

3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

4)The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: sales9@ldfoodmachine.com