Why do you choose the Shandong Leader Machinery Co.,ltd. Over 60 years experience factory palm oil milling machine?

1.Healthy! Pure mechanical squeezing craft maximally keeps the nutrients of the oil plants.No chemical substances left

2. High working efficiency! Due to a high working efficiency of the screw oil press machinery,both time and power can be saved.

3. Long durability! All the parts are made of the most suitable material and treated with refined crafts, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4. Over 60 years experience factory palm oil milling machineCost-effective! Low investment! The wearing parts on the oil press machinery such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and there is no need to displace the whole machine.

Over 60 years experience factory palm oil milling machine

Product Description

I. Palm oil raw materials of palm oil milling machine

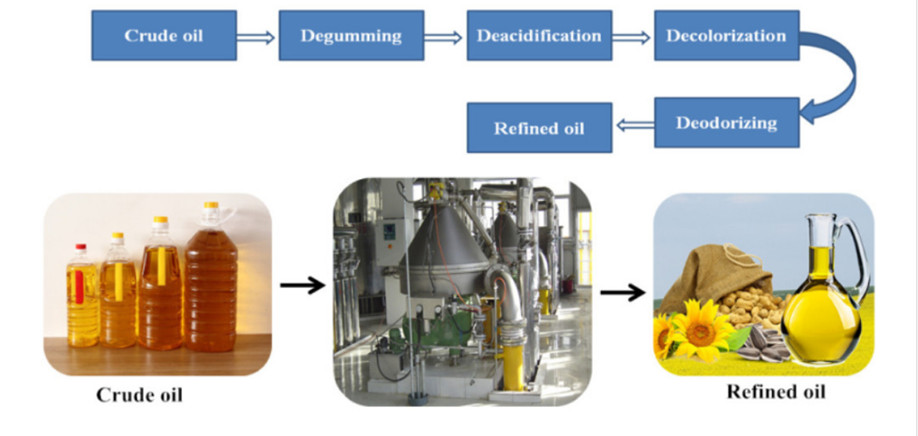

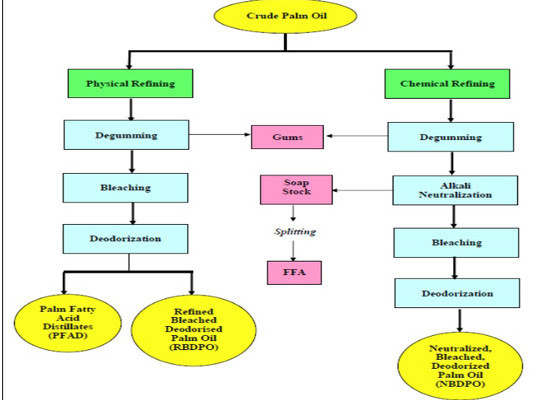

II. Palm crude oil whole process of palm oil milling machine

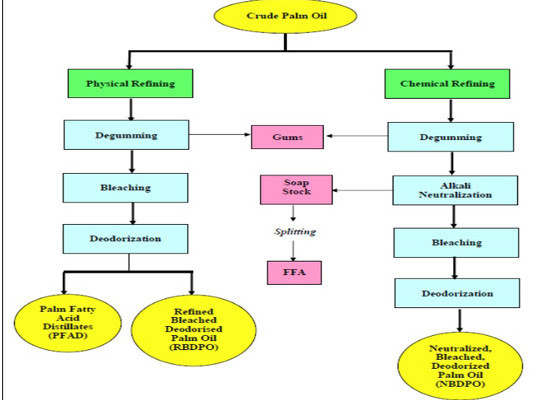

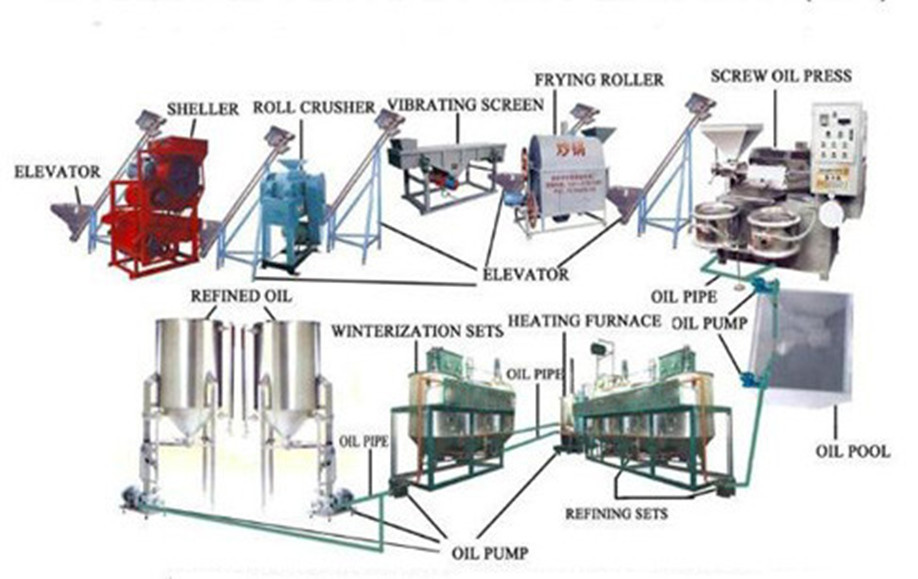

(1) Craft flow palm oil for palm oil milling machine

A. Palm fruit/bunch → sterilization → threshing → digesting → clarification → purification

→dring → CPKO→ refining → decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

B. Palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil , RBDPK olein & RBDPK stearin

(2) Main Produce Scope Palm oil processing of palm oil milling machine

♦ 3T/H, 5T/H,10T/H,30T/H,45T/H,60T/H,80T/H,100T/H(TON/HOUR);

(3) palm oil processing machine main sections for palm oil milling machine

NO. |

Main section |

Main machine |

1 |

Fresh palm fruit bunch reception section |

Loading ramp |

2 |

Sterilization section |

Sterilization tank |

3 |

Threshing section |

Threshing Machine c/w Platform |

4 |

Pressing section |

Screw presser |

5 |

Oil clarification section |

Clarification Tank |

6 |

Fiber separation section |

Depericarper Column |

7 |

Palm kernel recovery section |

Nut sheller |

8 |

Engine room |

Diesel generator |

9 |

Boiler house |

Boiler |

III. Pictures of palm oilproject for palm oil milling machine

Company Information

IV. ABOUT LD &OILS MACHINERY CO.:

♦ More than 60 years manufacture histories.

♦ Largest oil machine manufacturer in China.

♦ 100,000 m² of factory total area and 580 senior engineering technicians.

♦ 23 National patents.

♦ 87 million yuan fixed assets.

♦ 150 million annual sales turnover.

V. LD COMPANY ADVANCED EQUIPMENTS:

VI. LD NATIONAL PAENTS:

VII. LD CUSTOMERS VISITING OVER THE WORLD:

VIII. STATE LEADERS VISITING TO LD:

Packaging & Shipping

VIII. LD CARGO DELIVERY:

Our Services

IX. LD PROJECT INSTALLATION:

X. LD OVERSEA EXHIBITION:

FAQ

XI. QUESTIONS & ANSWERS OF LD:

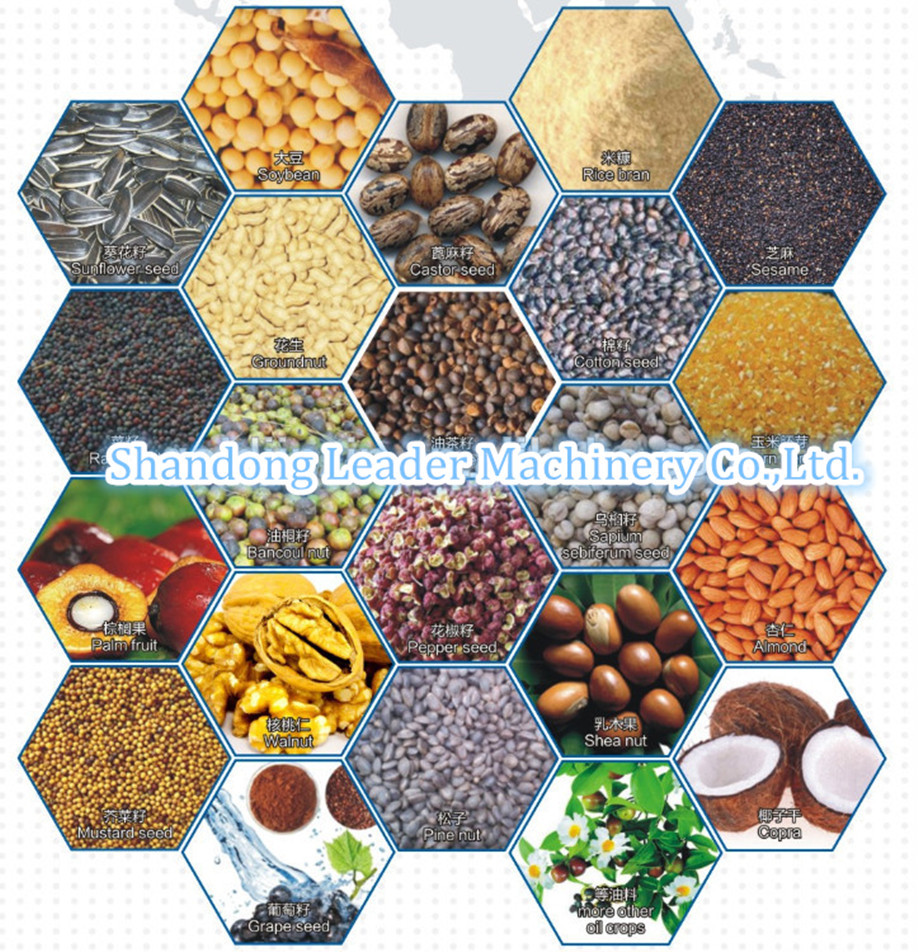

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. For example, rice bran, corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What's the capacity?

A: 30-5000 tons per day. Of course, we can manufacture as customized order.

3. Q: How long is the warranty?

A: After installing qualified, we guarantee the main parts nature time 1 year.

4. Q: Can you install the machine in local place?

A: Yes! We are a collection of r &d, design, manufacture, installation and training! We can make turnkey project.

5. Q: How to contact with you?

A: Kindly check the below picture.

If you want to know more information about our project, Please Leave Message on below form and click "send" below. I will reply to you. Thanks!

Introduction of Shandong Leader Machinery Co.,ltd. Over 60 years experience factory palm oil milling machine

Solvent condensation system combines with evaporation system closely, and evaporative condenser and steam stripping condenser all work under negative pressure.

Non-condensable gas enters the energy saver from the shell of the first evaporator. In energy saver, noncondensable gas exchanges heat with condensate from the evaporative condenser.

Finally, the condensate temperature discharged from energy saver is increased, and the solvent separated water from going to the solvent holding tank.

AAA1

Advantage of Over 60 years experience factory palm oil milling machine:

1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

2) Meal is send to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

AAA2

3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

4)The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: sales9@ldfoodmachine.com