Introduction of professional manufacturer of brush cassava washing and peeling machine:

1>. professional manufacturer of brush cassava washing and peeling machine have main ten parts: Reception Station,Sterilizer,Threshing,Press,Clarification, Kernel Recover, power station, boiler station, water treatment plant, oil storage tank.

2>. Shandong Leader Machinery Co.,Ltd. use the Fresh Fruit Bunch, because the palm fruit rancidity is very fast, if the rancidity will be influence the palm crude oil acid value, if the acid value is very high, the refining efficiency will drop.

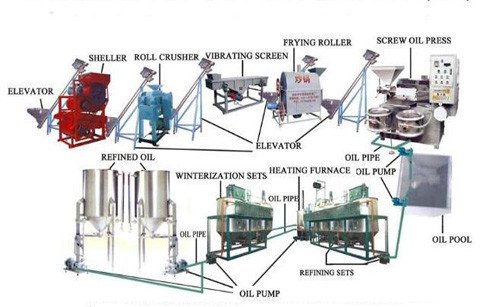

Working principle of Auxiliary Machine For Oil Press:

1. Transferred by the triangle belt, the electromotor drives the spiral shaft.

2. Oil plants being carried toward to the end of the machine by rotating squeeze spirals.

3. With the space between spirals and loops becoming smaller,the pressure in the chest is bigger.

4. During this process, oil plants are smashed and the tissue cells are destroyed, then oil is separated from oil plants.

5. After extracted, oil plants turns to be cakes containing low oil and is discharged in thin slices from the end.

cassava washing and peeling machine

1.material : stainless steel

2. widely used in round, oval fruits and vegetables

cassava washing and peeling machine

Details

The brush cleaning peeling machine mainly consisted of motor, transmission, 8-13 rollers, etc. We designed according at home and abroad on the characteristic of the root vegetable processing machinery, using brush theory, widely used in round, oval fruits and vegetables such as ginger, carrot, taro, potato, Spanish potato, sweet potato, kiwi fruit and other root vegetable cleaning and peeling.

Feature

Cleaning and peeling with large capacity, high efficiency, low energy consumption, continuous cleaning, easy to operation, long service life, etc. Brush roller material rolling from nylon cord.

Specification

Model |

Power |

Dimension |

Weight |

Capacity |

GLT1200 |

2.2kw/380v |

2120x840x900mm |

300kg |

1200kg/h |

GLT1500 |

3kw/380v |

2400x840x900mm |

380kg |

1500kg/h |

GLT2000 |

4kw/380v |

2900x840x900mm |

460kg |

2000kg/h |

GLT4000 |

4kw/380v |

3050x1200x1160mm |

600kg |

4000kg/h |

Pictures