Customers-- Palm Oil mill /Palm Fruit Oil Mill

Shandong Leader Machinery Co.,ltd. have customers from all over the world like Uzbekistan, Kyrghizstan, Kazakhstan,and Canada, Chile, Argentina,Ethiopia, india, malaysia, Zambia, Nigeria, Russia , Turkey, Tunisia ,more than 100 countries overseas.

3. Advantage of tea seeds oil making machine

(1) Simple design, small volume and light weight, easy to handle and move.

(2) Easy for operating, low labor intensity and high economical profit.

With ISO,CE certificate Palm Oil mill /Palm Fruit Oil Mill

Company InformationLD Best Grain & Oil Machinery Engineering Co., Ltd. which specialize in producing edible oil mechanical equipment, a group enterprise integrating scientific research, manufacturing, sales as one . BEST has been undertaking more than 200 sets of oils and fats production turnkey projects . Our company has passed the international quality management system ISO 9001 and CE certificate. It has the qualification of manufacturing one or more types of pressure vessel .

Go with BEST, to be the best. Do what you think-BEST!

Palm oil mill machine factory supplier

Due to the particularity of the oil palm fruit structure, so the process of making oil with other oils difference is bigger.

1. Sterilization Remove yeast

High-temperature cooking of oil palm fruit, destroy flesh of lipase, in order to avoid oil increased free fatty acid content , In addition, you can make the fruit is soft, easy to mechanical threshing, is conducive to the subsequent pit peel, nuts reduce breakage.

2. threshing

Oil palm fruit accounted for about 60% of the whole fruit bunch. Is the purpose of threshing separating from oil palm fruit bunches on.

3. Mashed and Cooking

Mashed and cooking to tear fruit skin, separate the pulp and the core and mash pulp tissue,heat to make pulp soft at the same time, and destroy the structure of pulp cells.

4. oil extraction

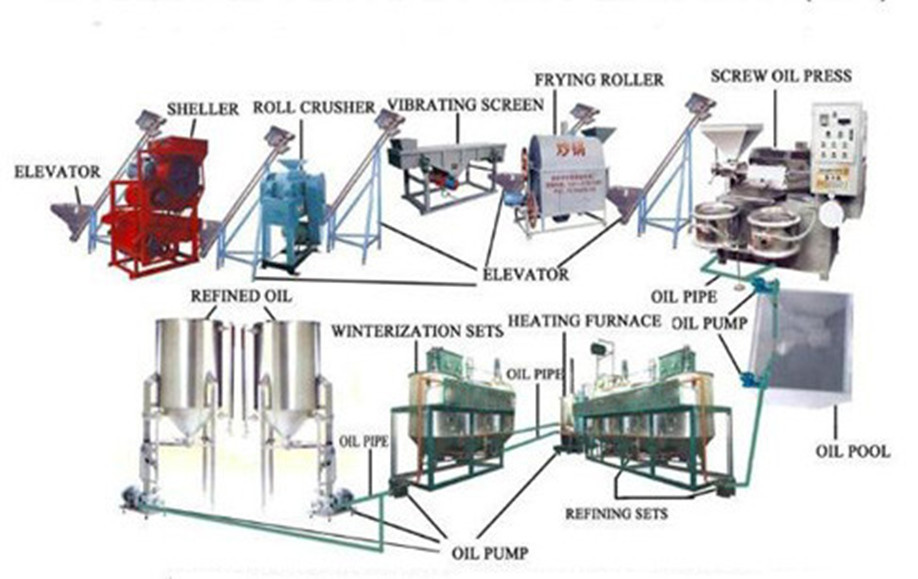

Grease making generally adopt continuous screw oil press, after squeezing can be divided into two parts: the mixture of oil, water, solid impurities; fiber and stone of the fruit .

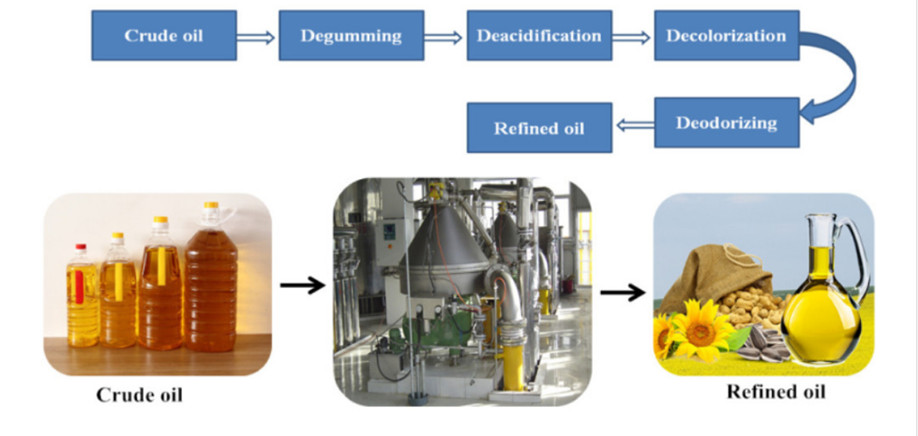

5. crude oil purification

Crude oil generally contains 66% fat, 24% water, 10% of non-oil solids, the process generally comprises: washing dilution, filtration, sedimentation settling tank, centrifuge, vacuum dryer, cooling, precipitate secondary settlement.The palm oil can besold directly or use for futher processing.

6.The sewage from all the plant will be processed by sewage treatment to reach discharge

standard.Sludge can be used for fertilizer in palm plantation.All the process cycle features with

short operation cyclye ,high automaticity,energy conservation and environment protection.

palm oil fractionation technology

palm oil fractionation technology developed by our company is with advanced technology,full computer control system and low cost of investment. It is also with high liquid oil yield,high purity solid fat,high economic benefit,and other advantegesetc.

Palm kernel oil pressing process includes crushing, flaking , steam-roasted , press The production technology and equipment are similar to those of general oil.

Main business field

---10-500T/H oil material first cleaning,drying and storage section turn-key project.

---100-3000T/D oil pretreatment,shelling and pre-press wokshop trunkey project:rice bran production line turn-key project.

---100-300T/D leaching workshop trunkey project.

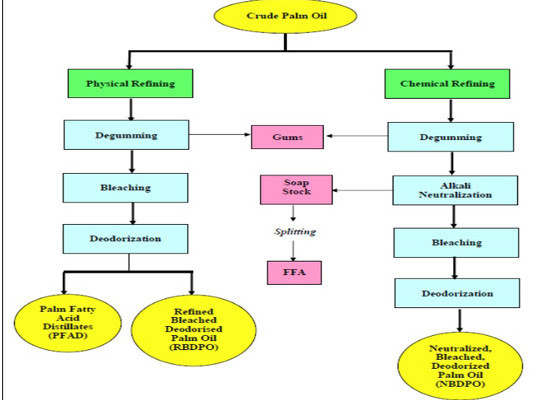

---30-1000T/D oil continuous grade oen or two physical(chemical)refining production line.

---20-3000T/D sunflower oil,corn germ oil dewaxing turn-key project.

---10-200T/D Fatty acid esterification production cooking oil production line.

Packaging & Shipping

Our Services

--- Ensure to timely provide complete sets of equipment and accessories.

--- Ensure that one-time installation debugging acceptance.

--- To provide high quality material with preferential price.

--- Free training technological operator to ensure the trained staff can operation independently

we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

Warranty period: 2 years from the date you bought our machine.

The following situations are not included in our warranty.

(1) The damage which you did not according to our service manual.

(2) Normal spoilage of the quick-wear part.

(3) Someone who can’t use and maintain the oil press machine.

Whether the oil press machine is in our maintenance range or not, our after-sale service team all can help you to repair.

Product Description of Palm Oil mill /Palm Fruit Oil Mill :

This series of Palm Oil mill /Palm Fruit Oil Mill are an excellent model of palm oil making machine through numerous experiments and long time usage by all of the world clients.The palm oil making machine has advantage of high efficiency, low consumption, simple operating, stable function, easy to maintain,high productivity and high oil output ratio

AAA1

Application of Palm Oil mill /Palm Fruit Oil Mill :

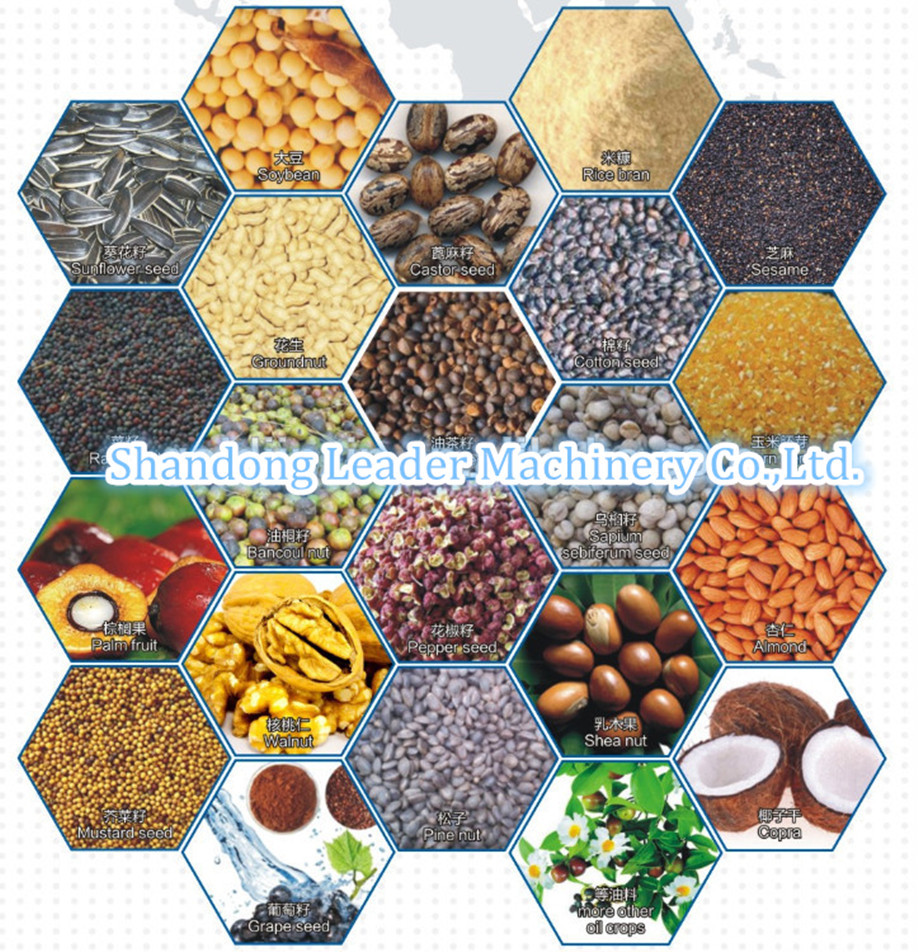

The Palm Oil mill /Palm Fruit Oil Mill is widely used in squeezing oil from vegetable oil seed,such as soybean, peanut, sunflower seed, cotton seed, sesame, tea seed, copra, jatropha curcas, castor seed ,etc. it is specially for the palm fruit better after adjusting its structure

AAA2

Palm Oil mill /Palm Fruit Oil Mill mill used to corn soybean peanut palm coconut rapeseed cooking oil press / making/extracting machine

are advanced oil processing machinery, characterized by their simple design, easy to use,wide suitability and continuous operation; and high productivity and high oil output rate.Moreover,theycan be used for various raw materials, as ground nuts, bean, rice bran,rape and cotton seeds, sesame, olive,sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: sales9@ldfoodmachine.com