Customers-- 40TPH palm fruit crude oil mini cold oil press machine with best sale-after service

Shandong Leader Machinery Co.,ltd. have customers from all over the world like Uzbekistan, Kyrghizstan, Kazakhstan,and Canada, Chile, Argentina,Ethiopia, india, malaysia, Zambia, Nigeria, Russia , Turkey, Tunisia ,more than 100 countries overseas.

3. Advantage of tea seeds oil making machine

(1) Simple design, small volume and light weight, easy to handle and move.

(2) Easy for operating, low labor intensity and high economical profit.

40TPH palm fruit crude oil mini cold oil press machine with best sale-after service

Product Description

PALM FRUIT

Oil press machine-Palm fruit are originated from Africa,then it has been introduced into Asia and developed in Malaysia,lndonesia,Palm trees generally have 25 years of growth,from the second to the eighteenth year is a mature period

Oil press machine-Each palm tree can produce fruit 360kg annually,or to say it can produce more than 3 tons of palm fruit in its life span

oil press machine-Normally palm trees can produce fruit after planting 2-3 years and have 8.8 meters row spacing.The planting density is about 138 per her hectare(60per acre)

Palm oil pressing line for palm oil processing plant- introduction:

a. Palm fruit reception:Transport FFB to reception station, flow to the scraper conveyor, conveyed to sterilizing station.

b. Sterilization: FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145°C

c.Threshing: After sterilizing, fruit bunch transported to thresh machine, separate palm fruit and empty fruit bunch.

d:Digesting: Before press palm fruit, should be crushed separated pulp and kernel

e.Oil press: After crushing and digesting, the maxture of palm fruit and kernel fall into special palm oil presser

f.Clarification:Filter the oil and use centrifuge to separate oil and impurities.

g. Kernel and fiber separation:After press, the kernel and fiber will be transported to kernel recovery station. Separating kernel and fiber, then the kernel go to kernel oil press.

h.Palm oil filteration: Use vibrating filter to filter the oil to remove impurities in it.

RECEPTION STATION for Oil press machine

Used for loading palm fruit from plantation to sterilizer,Reception adopt steel structure and concrete.Save equipment cost and construction cost.

Have hydraulic control system, hydraulic door open/off automatic achieve continuous operation. Reduce operator,operate more easily and improve work efficiency.

STERILIZIG TANK for Oil press machine

The sterilizing tank uses direct steam to process,which can reduce activity of the enzyme,prevent the rancidity,ensure the good quality of the crude oil.At the same time,it is good for the trashing process.

VERTICAL STERILIZER for Oil press machine

Vertical sterilizing system:invented by QIE group,it has beaten the traditional horizontal sterilizing technology,the new system has realizeb the fully continuous and automatill working,it also has lowereb the labor intensity,reduced the land needed for the plant,and enhanced the efficiency,at the same time,it needs less energy,which can reduce the investment,as well improvement the stetilizing effect, what's more,it can rise the oil extraction rate by 1%or2%,which can help to increase the economic benefit.

Vertical sterilizing tank:controlled by hydraulic system,it can work fully automatically.it needs less land,less operators.We are making further progress to improve the structure of the sterilizing tank,to solve the material getting out.(Sterilizing tank feeding hole,discharge hole)

HORIZONTAL STERILIZER for Palm oil processing machine

Horizontal sterilizing tank:with larger capacity,it can work continuously,it uses back pressure container and direct technology.The process is divided into 3 passages,The temperature is 150℃,duration is80-90 mins.LD Grain and Qil Machinery Co,Ltd designed the horizontal sterilizing tank hydraulic system exclusively,which can reduce the labor needed in sterilizing station,the processing line more automatic.

THRESHING STATION for Oil press machine

Fresh palm fruits separate from bunches by thresher rotary drum rotating. Palm fruits are conveyed to digesting tank by elevator.Empty bunches are conveyed out of factory by scraper conveyor. Thresher shaft uses once forging technology.The equipment is stronger and hasloner life.Atthe sane,our company developes non-shaft thresher drived by chain.in this way,it reduces power loss and saves production cost.

DIGESTOR for Oil press machine

Inside of sterilizer,there are some baffle and stirring arm,under the drive of top motor.Baffles break off the palm fruit,then heat palmfruit pulp. So that can press oil easily.Get higher oil yield.Meanwhile there is directly steam inlet digester,to adjust material moisture.

PRESSING MACHINE for Oil press machine

The palm fruit oil yield increases by adjusting material and temperature and temperature in digesting tank.Digesting tank uses liquid level control,so material can distribute automatically and equipment runs fully automatically.Pressing machine uses hydraulic control system to adjust spacing between pressing bolts,So it can be suitable for various palm fruit species and guarantee the oil yield.

KERNEL RECOVERY STATLON for Oil press machine

Using air duct system to separate palm shell and kernel. Meanwhile, using special mud bath equipment to separate palm kernel and shell according to their different density.So it has high separation rate.

There are some fiber cover the palm nut,in order to get palm kernel should remove palm shell. Fiber and shell is very good resource for boiler fuel.

LD Best Grain and Oil Machinery Engineering Co., Ltd keep improving the technology,produce palm shell mill,fiber collection system,polishing machine etc for the main equipment of kernel station.Improve the work efficiency highly.Separate fiber totally,reduce palm kernel broken rate.

CLARIFICATON STATION for Oil press machine

Oil purifying system:using latest technology,on the premise that guarantee oil quality,we try our best to reduce machine investment and oil loss.in actual production, it has been verified that using new technology can reduce oil loss below1.3%

The specification of crude palm oil

Item |

Standard |

Smell and taste |

The original smell and taste of crude oil |

Moisture and volatile matter (%) ≤ |

0.20 |

Insoluble impurities (%) ≤ |

0.20 |

Acid value (mgKOH/g) ≤ |

4.0 |

Peroxide value (mmol/kg) ≤ |

7.5 |

KERNEL PRESSING TECHNOLOGY for Oil press machine

LD Best Grain and Oil Machinery Engineering Co., Ltd develop cold press and hot press,keep good quality palm kernel oil and high oil yield.Meanwhile increase the press capacity.reduce equipment investment.

Palm kernel oil can be processed to cocoa butter,Artificial cheese,etc.Palm kernel cake can used for animal food.it's a good resource of profits.

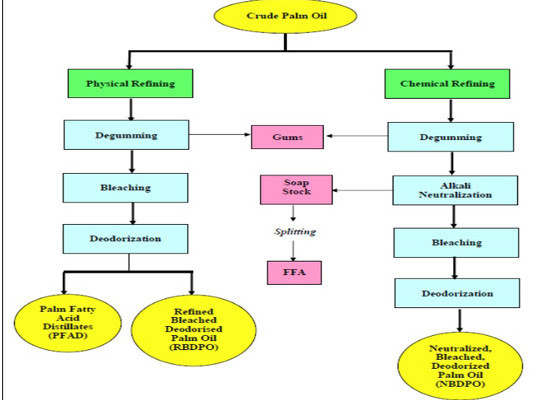

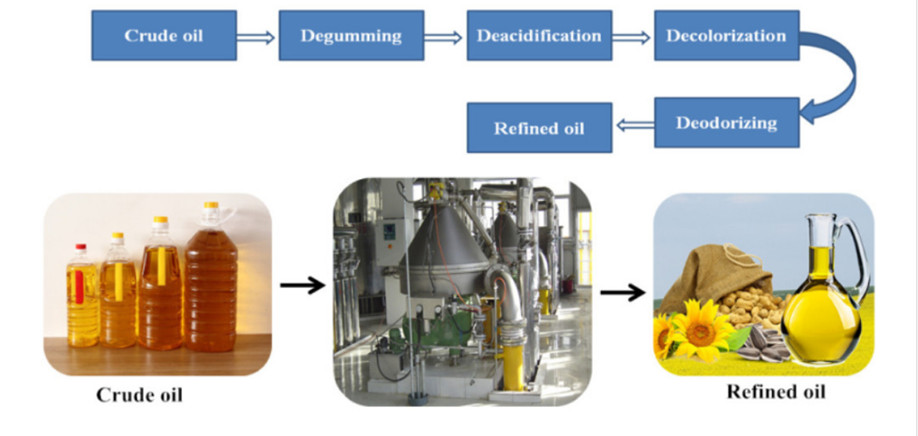

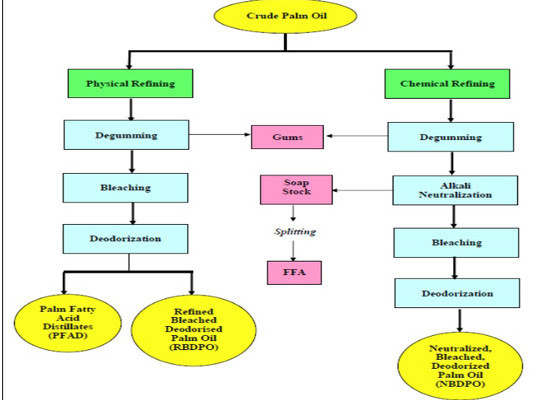

PALM OIL REFINERY TECHNOLOGY for Palm oil processing machine

Oil refining is based on the difference of oil and impurities in the physical and chemical properties,separate the grease and impurity by some technical ways in order to improve the oil edible,storage storage stability and safety process.Oil refining process is divided into chemical refining and physical refining.

The refining technical and equipment we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity,we can use batch,continuous,physical and chemical refining design.the product oil can reach first to fourth grade.Guarantee the highest.quality in lowest cost.

PALM OIL FRACTIONATION TECHNOLOGY for Oil press machine

Palm oil fractionation technology developed by LD Company is with advanced technology,full computer control system and low cost of investment.it is also with high liquid oil yield,high purity solid fat,high economic benefit,and other advantages etc.

Palm oil fractionation technology is a new oil processing technology.Using palm oil fractionation technology can get 8℃,10℃,14℃,18℃,24℃,33℃,44℃,55℃ etc,different melting point's palm oil product.At the same,time.it can also be used to do cottonseed oil,and other animal oils.This prominently improves the added value of the oil products,increases the economic benefit of enterprise.

The specification of refined palm oil

Item |

Standard |

Color (Lovibond Cell 133.4mm) |

R2.0 Y20 |

Smell and taste |

No smell and good taste |

Transparence |

Clear and transparent |

Moisture and volatile matter (%) |

≤0.05 |

Insoluble impurities (%) |

≤0.05 |

Acid value (mgKOH/g) |

≤0.20 |

Peroxide value (mmol/kg) |

≤5.0 |

Smoke point (°C) |

≤215 |

MAIN BUSINESS FIELD

1. 1TPH Palm fresh fruit bunch(FFB)press project manufacture,installation and Turnkey project

2. 2T/H-10TH Palm fresh fruit bunch(FFB)press project manufacture,installation and Turnkey project

3. 15T/H-30T/H Palm fresh fruit bunch(FFB)press project manufacture,installation and Turnkey project

4. 40T/H-100T/H Palm fresh fruit bunch(FFB)press project manufacture,installation and Turnkey project

5. 5T/D-100T/D Palm oil refinery project production

6. 5T/D-100T/D Palm oil fractionation project production

7. Palm oil mill equipment remodelling and maintenance

8. Equipment spare part supply

9. Project design and technology support

Company Information

LD Best Grain & Oil Machinery Engineering Co., Ltd. which specialize in producing edible oil mechanical equipment, a group enterprise integrating scientific research, manufacturing, sales as one . BEST has been undertaking more than 200 sets of oils and fats production turnkey projects . Our company has passed the international quality management system ISO 9001 and CE certificate. It has the qualification of manufacturing one or more types of pressure vessel .

Go with BEST, to be the best. Do what you think-BEST!

Packaging & Shipping

Certifications

Our Services

1.Technology Strength: nearly one century's history of manufacturing machinery,has a very valuable experience in manufacturing and technology services. Ensure every machine perfect.

2.Perfect After-sales Service:We have a professional service staff, and timely communication with the user, so that each machine is a "hen"lay eggs to make money.

3.Preferential Price:Company specialized production, large product yield and low cost; adopt modern management techniques and tools to maximize savings cost for the user to save every penny.

4.Good Reputation:Through the company's one century of efforts to make our products in Africa, Asia, Europe, America has an unparalleled reputation.

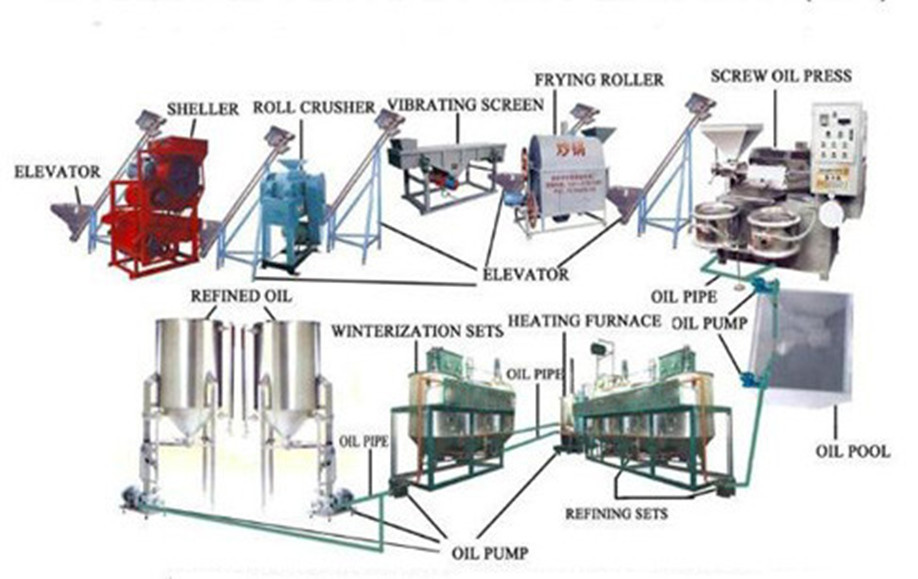

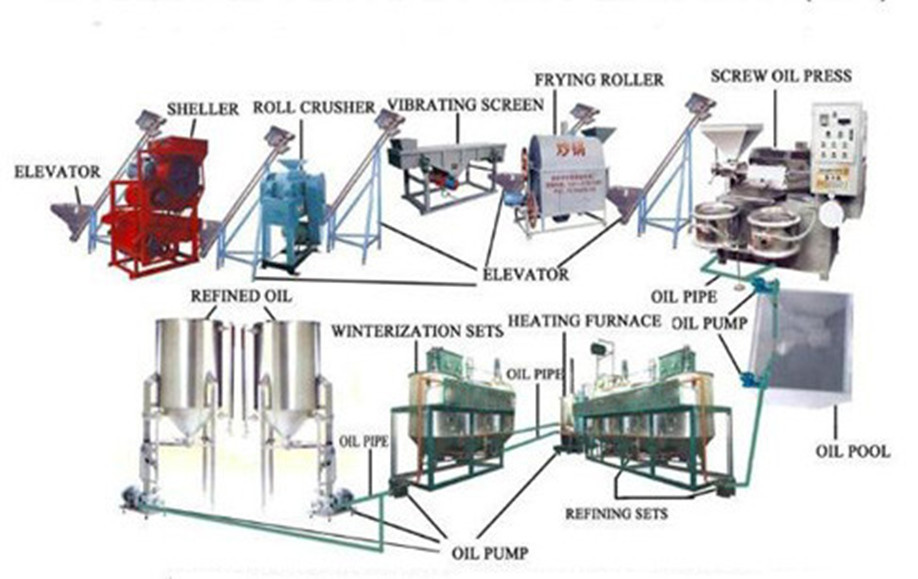

Product Description of 40TPH palm fruit crude oil mini cold oil press machine with best sale-after service :

This series of 40TPH palm fruit crude oil mini cold oil press machine with best sale-after service are an excellent model of palm oil making machine through numerous experiments and long time usage by all of the world clients.The palm oil making machine has advantage of high efficiency, low consumption, simple operating, stable function, easy to maintain,high productivity and high oil output ratio

AAA1

Application of 40TPH palm fruit crude oil mini cold oil press machine with best sale-after service :

The 40TPH palm fruit crude oil mini cold oil press machine with best sale-after service is widely used in squeezing oil from vegetable oil seed,such as soybean, peanut, sunflower seed, cotton seed, sesame, tea seed, copra, jatropha curcas, castor seed ,etc. it is specially for the palm fruit better after adjusting its structure

AAA2

40TPH palm fruit crude oil mini cold oil press machine with best sale-after service mill used to corn soybean peanut palm coconut rapeseed cooking oil press / making/extracting machine

are advanced oil processing machinery, characterized by their simple design, easy to use,wide suitability and continuous operation; and high productivity and high oil output rate.Moreover,theycan be used for various raw materials, as ground nuts, bean, rice bran,rape and cotton seeds, sesame, olive,sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: sales9@ldfoodmachine.com