Specifications

Microwave drying&sterilization machine for fruit1.Rapid/symmetrical drying

2.EnerLD saving

3.Keep fresh&ingredient

4.CE

Industrial conveyor belt tunnel type microwave fruit LD dehydrator machine equipment

Brief introduction

1. Vegetable microwave drying LD machine

2. Save egerLD, loss enerLD less

3. Fast drying, unoform drying, save time

4. Material is overall 304# stainless steel, have no pollution upon food

5. Safety, easy to control, have no pollution upon environment

6. LD efficient, keep fresh, keep original ingredient and nutrition

Mainly application of microwave drying machine for fruit

Microwave drying dehydration machine, microwave LD machine for vegetable, microwave dehydrator machine, microwave drying and sterilization equipment is very widely used in drying and sterilizing powder, granular, flakes or colloidal form foods, nutritional health products, grain, agricultural and sideline products(rice, cornmeal), bamboo shoot, tea(wild chrysanthemum flower, broadleaf holly leaf, lotus leaf, green tea, black tea, puer tea), ginseng, mushroom, agaric, ganoderma, vegetables and fruits(spinach, carrot, parsley, onion, mango slice, apple slice, lemon slice, kiwi slice, banana slice etc.), preserved fruits, red jujube, non-fried(oil saving) instant noodles, noodles, cookie, biscuit, rice powder noodles, chicken jerky, beef jerky, preserved meat, dried fish, seafood(seaweed, sea cucumber, laver, kelp, sardine, shrimp, abalone etc.), pickles, spices(pepper powder, Chicken essence, beef essence, pork essence, yeast extract, seafood extract, seafood soup essence, seafood soup powder, spareribs soup pure, spareribs soup powder, spice, chili powder, ginger powder, garlic powder, aniseed, cinnamon, angelica, cumin, cassia bark, fennel etc.), egg yolk powder, jam, a variety of small packaging and pet food mildew sterilization preservation.

Main features of microwave drying machine for fruit:

1.Save time ,fast

Microwave sterilization is microwave with food , bacteria, and microbial direct interaction, heating and non-thermal effect worked together to achieve rapid warming sterilization purpose, the processing time shortens LDly, the sterilization function of all kinds of material in commonly just need 3 to 5 minutes.

2.Low temperature sterilization keep nutrients and the traditional flavor

Microwave sterilization is through the special heat and non- hot effect,with low temperature and a relatively short period of time to obtain the sterilizing effect. General sterilization temperature in the 75 to 80 degrees Celsius, can achieve the result, moreover, microwave processing food can hold more nutrition composition and color, fragrance, taste, shape and flavor, has the expansion effect. Such as conventional thermal treatment of vegetables keep vitamin C are 46%- 50%, and is 60%- 90% microwave processing; Conventional heating pig liver vitamin A keep rate was 58%, and 84% for microwave heating.

3.Save enerLD, loss energu less

Microwave is directly on the food, and therefore had no extra thermal enerLD consumption . In contrast, general , electricity saving 30% -50%. Microwave enerLD as enerLD's utilization rate of 75%,Compare with far infrared and steam dry reduce enerLD consumption by 25% or more.

4.Even completely

Because microwave can through the whole food ,when process the food , the surface and inner can befuncted at the same time, so sterilizing uniform thoroughly.

5.Easy to control

the device can be used when open,no need waiting, which is not hot inertia, convenient operation, the microwave power can adjustable, transmission speed can be adjusted continuously from zero, it is easy to operate.

6.The equipment is simple, the craft is advanced

Need not complex facilities , as long as have water, electricity,such basic conditions .

7.Improve working conditions, and save cover area

Equipment working environment 's requirement is low, the noise is small, LDly improving working conditions, and a complete set of microwave equipment operation just 2-3 people.

Technical parameter of JN-12 microwave drying fruit machine

Power supply |

380V±10% 50HZ±1% three-phase five-wire |

|

Microwave Output Frequency

|

2450±50MHz |

Microwave input apparent power |

42KVA |

Microwave output power |

30KW |

Microwave power adjustment range |

0-30KW(adjustable) |

Ambient temperature |

-5-40°C |

Dehydration capacity |

30-42kg/h |

Relative humidity |

80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas |

Overall dimension(L*W*H) |

10500*1440*1750 mm |

Transmission speed |

0-10m/min(adjustable) |

HeigLD of the inlet and outlet |

60 mm |

Microwave leak |

accord with a country GB10436-89 standards( |

Equipment safety |

accord with GB-5226Electrical safety standard accord with a country GB16798-1997 Food machinery health security index |

We also can design the equipment according your requirement, so just tell us the requirement of yours, and let us choose or design a suitable model for you.

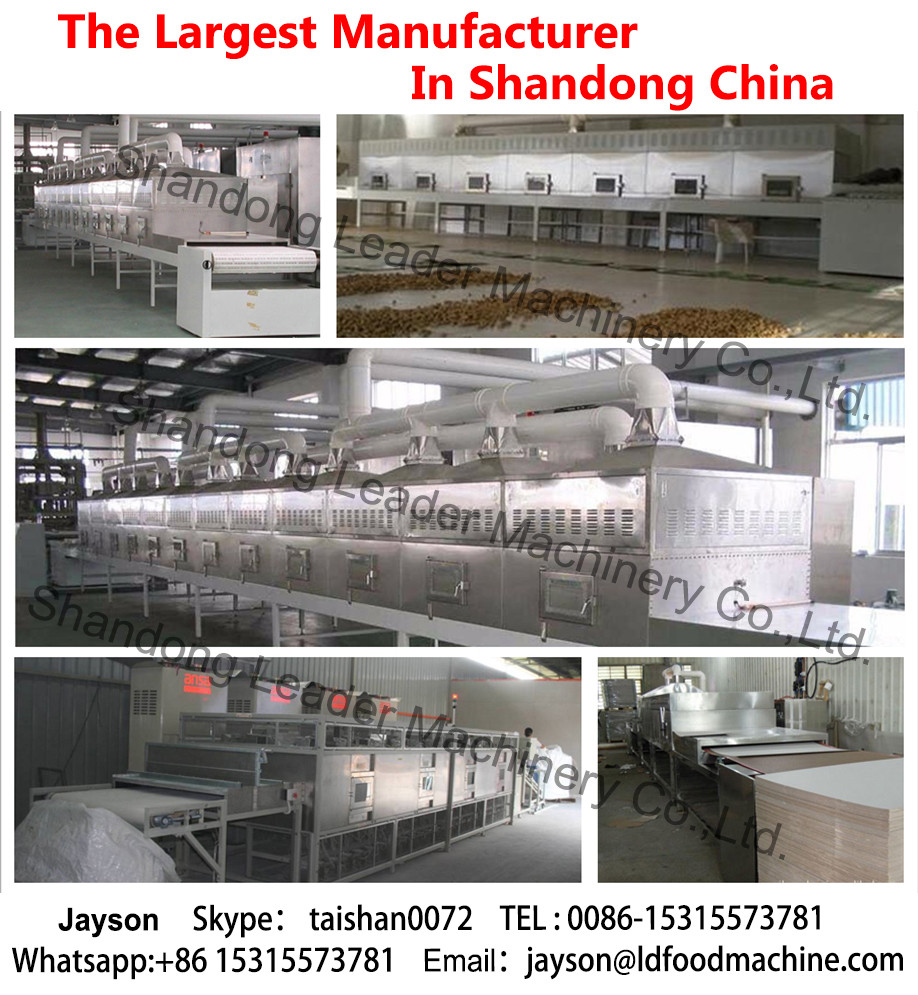

Pictures reference

Welcome to contact to me to know more details