Specifications

microwave LD and sterilizer (304 # food grade stainless steel )fast drying

sterilizing effect cfusave enerLD

microwave LD and sterilizer (304 # food grade stainless steel )

We are specialized in this area for many years, and we have do test many time for drying and sterilizing spice and certificate products, the effect is wonderful. It's easy to use and control,and it needn't cost too much enerLD.

This machine is a kind of continuous tunnel drying equipment, it is very convinent to used in industrial batch production.

Application Range (for food products):

Mainly used for spice and condiment products, such as pepper powder, Chicken essence, beef essence,pork essence,yeast extract,seafood extract,seafood soup fine,

seafood soup powder, spareribs soup pure,pure,spareribs soup powder,spices,chili powder,ginger powder,

garlic powder,aniseed,cinnamon,angelica,cumin,cassia bark,fennel etc),egg yolk powder,

Technical parameters

Power supply |

380V±10% 50HZ±1% three-phase five-wire |

|

Microwave Output Frequency

|

2450±50MHz |

Microwave input apparent power |

≤70KVA |

Microwave output power |

≥50KW |

Microwave power adjustment range |

0-50KW(adjustable) |

Ambient temperature |

-5-40°C |

Dehydrate |

50kg/h |

Relative humidity |

≤80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas |

Overall dimension(L*W*H) |

11810*1440*1750 mm |

Transmission speed |

0-10m/min(adjustable) |

HeigLD of the inlet and outlet |

60 mm |

Microwave leak |

accord with a country GB10436-89 standards(5 mw/cm^2) |

Equipment safety |

accord with GB-5226Electrical safety standard accord with a country GB16798-1997 Food machinery health security index |

Feature:

1. Improve the quality of products,no cracking,no shrink,no deformation,insect-resistant;

2. Drying and insecticidal proceed at the same time,good effect;

3. Drying fast,low enerLD consumption,lower the cost,increase efficiency;

4. No environmental pollution,particularly applicable to the production process factories which located

in the strict environmental requirements area;

Operating principal:

This microwave source adopts continuous microwave magnetron as its microwave oscillation source. The continuous magnetron is a kind of cross-field microwave radio tube, the direct current field and the stationary magnetic field are vertical. The anode of the magnetron is a complex system of resonance. The anode block consists of many little resonant cavity. Between them there is inductance coupling, so the anode block is the crossover network of microwave. The electron eradiated from the cathode of the magnetron will firstly be affected by the direct current field and curl like an angle. While the electrons are moving from the cathode to the anode, the contrail of their movement is like a swing vibration. Under the condition of synchronism between high frequency field and electron cloud, the electron contrail will rise toward the anode direction and form electron spoke. Among the spoke, while the electrons are carrying through synchronistically, they will change the potential enerLD into high frequency enerLD and increase the high frequency breadth. After the magnetron is started, the direct current which is instored in the resonance cavity will be changed into super-high frequency enerLD, finally, microwave source of enough power will exported through wave-guide.

Microwave heating and drying, sterilization characteristics:

1.Heated rapidly, uniformly

Without heat conduction process, in an instant it can penetrate into the material is heated, the penetration depth of a few centimeters or even tens of centimeters, seconds to minutes microwave into heat. Microwave selective heating, and will allow more uniform heating.

2.Efficiently

Material containing moisture can easily absorb microwave heat, therefore, almost no other losses in addition to a small amount of transmission loss. Microwave heating compared with the far-infrared heating, saving enerLD 1/3 to 2/3.

3Anti-virus sterilization preservation

Microwave heating with thermal effects and biological effects, therefore, at lower temperatures, anti-virus bacteria and bacteria; can save the material activity and food vitamins, color and nutrients.

4.Advanced technoloLD, continuous production

As long as the microwave power to heat or to terminate. Transmission system to ensure continuous production, saving capabilities.

5. safe

The microwave enerLD is to control the metal is heated indoor wave tube work, microwave leakage is effectively suppressed. Radiation hazards and harmful emissions, does not produce waste heat, neither contaminate food, do not pollute the environment

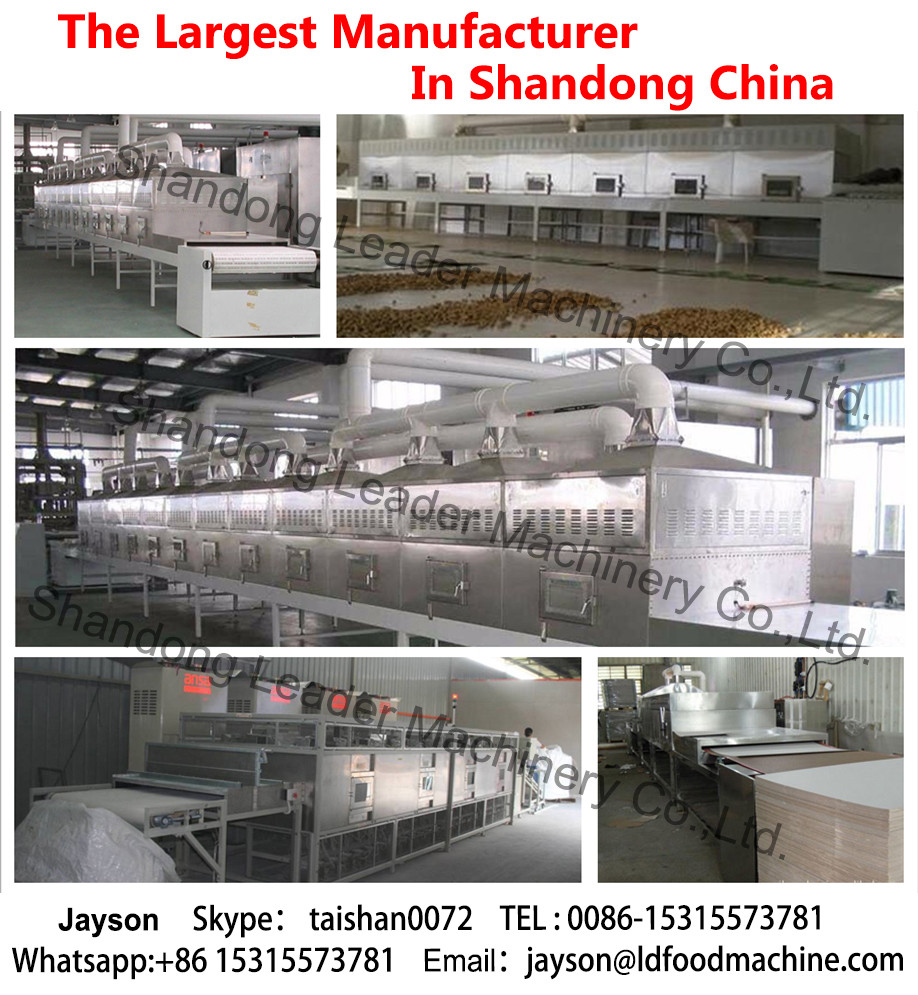

The picture:

If you are interested in our equipment-microwave drying&sterilization machine,please feel free to contact us.

Looking forward to your sooner inquiries.

Thank you very much.

Jinan Microwave Trade.,Ltd