Popcorn Production Line

Popcorn product introduction: With the continuous development of puffed food industry, puffed food has become global internationalization.More and more expanded products have entered the vision of ordinary consumers. As a new generation of popular puffed products, spherical popcorn is developing rapidly all over the world, featuring novel appearance and crisp taste. Become a new generation of consumers like consumer products. For the vast number of consumers in the journey, rest time to provide a visual feast.

Popcorn production line: Popcorn production line as a new generation of puffed food research and development of new products.A batch of semi-automatic popcorn production equipment has been replaced in our country. The equipment can be completed at one time from feeding to packaging. The single machine blasting output is 80-100 kg/h. The production line can be blasted continuously according to the equipment configuration: 80-400 kg/h. The production factors such as low blasting volume, unsustainable production and unstable product have been solved.Popcorn production line can produce products: spherical popcorn, American popcorn, ordinary popcorn and other products, according to the different raw materials, different products of blasting.

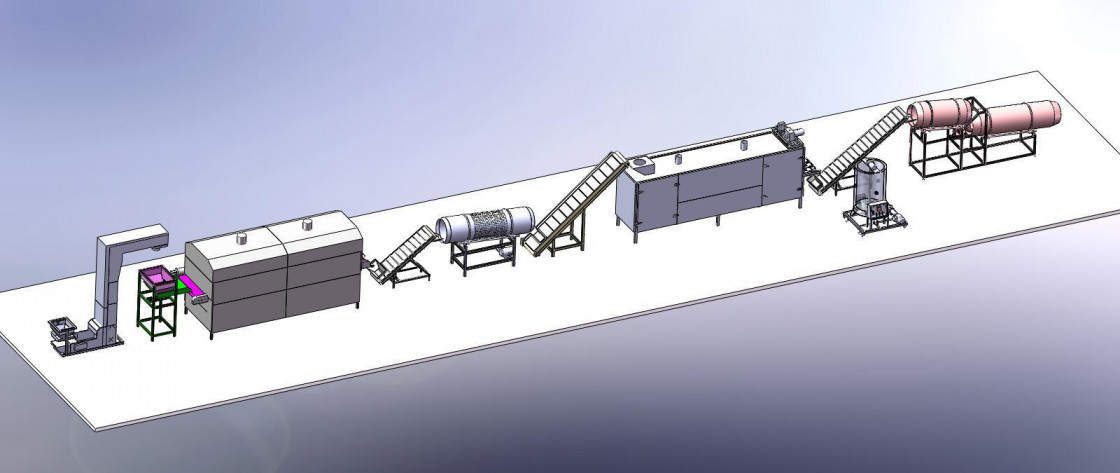

Technology Introduction: Corn Feeding - High Temperature Blasting - Dehulling - Spraying Sugar - Drying - Cooling - Packaging

Equipment Configuration: Vibration Feeding - High Temperature Blasting Furnace - Rotary Peeling Machine - Sugar Spraying System - Multi-layer Belt Dryer - Single Layer-Cooler-packer

Vibration feeder: The corn to be blasted is stored within the hopper weighed by the vibration feeder. The feeding speed is 80-120 kg/h by adjusting the frequency of the electromagnetic vibrator. The feed is uniform and stable.High temperature blasting furnace: a new generation of continuous corn blasting equipment, continuous feeding and discharging.Automatic temperature control, stable operation, simple operation, start-up can be discharged.

Rotary peeling machine: The hard surface of corn particles after blasting is knocked down by tumbling of raw materials, and the bottom is equipped with an automatic waste recovery device system.Sugar Spraying System: Sugar Cylinder - Sugar Spraying Cylinder - Feeder - Drum.Sugar sprayer uses advanced electromagnetic diaphragm pump to output raw materials. Sugar spraying flow can be more intuitive adjusted. The sprayed liquid combines with popcorn in a single drum. The drum rotates with animal feed rolls, so that the sprayed liquid on the product surface is even and smooth.

Drying equipment: The popcorn is dried and dehydrated to improve the taste of the product. According to the drying output, it can be divided into five-meter five-layer oven, eight-meter five-layer oven and ten-meter five-layer oven. The multi-layer reciprocating oven has the characteristics of small area and energy saving. According to the use of heat sources, it can be divided into electric oven and gas oven.

Cooler: The popcorn from the drying box has a certain temperature, which is convenient for the packaging behind the product to cool down quickly. The stainless steel material, according to the output, chooses the different length and width of the cooling conveyor packaging machine: according to the final raw material, chooses the packaging bags to pack timely.