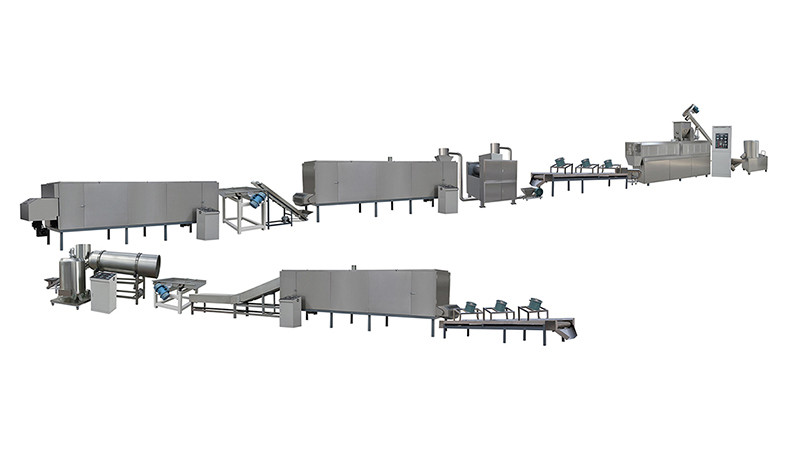

Corn Flakes Process Line

Corn flakes are made by Will Kellogg, an American medical doctor.It was invented in Michigan, USA. In the late nineteenth century, they sought a basic healthy vegetarian diet in order to promote the healing of patients. Their prescription is a kind of cooked, pressed and hot-dried corn, which is made into thin, crisp flakes. Add a little salt and you can eat it.

Corn cultivation in China has a long history, but the Chinese people came into contact with cornflakes at first when they went abroad to eat breakfast cornflakes in hotels. They were impressed that cornflakes tasted good and were easy to eat. After taking it home, we recommend enterprises to develop corn flakes. However, the seemingly simple corn flakes are difficult to form a modern industrial scale production for a long time. The main reason is that the tableting process has not been mature in China, and this situation has been improved in recent years.

Corn flakes must be dehulled and degerminated. In order to achieve uniform air bubbles in the later stage, we crush corn into about 60 meshes of fine particles. The powder enters the modulator and steam pre-mixing, and then goes into the puffing machine to ripen and granulate. This saves time and production space compared with the previous cooking method, and the degree of ripening is highly consistent, the particles are uniform, the product is very beautiful, and the particles are cold. After that, it enters a new type of tablet press. The tablet press adopts water-cooled constant temperature, so that particles can enter the tablet press effectively to avoid adhesion effect. Multistage tablet pressing patented technology makes the tablet more uniform and uniform in thickness.

The equipment adopts hydraulic control to control the thickness of finished products. The operation is simple and the control precision is consistent. After flaking, the flakes can be fully expanded in a high-temperature air-blast furnace at 300-320 degrees Celsius in about two minutes. The surface bubbles are uniform and the color forms an attractive golden yellow. In order to make various flavors of cornflakes, the spraying process is to spray different flavor materials evenly on the surface of the expanded cornflakes, and then form different flavors of cornflakes, and then enter the microwave oven. On the one hand, sterilization, on the other hand, drying the surface coating. Finally, enter the packaging stage, into major supermarkets, attractive and nutritious cornflakes fly into ordinary people's homes.