Small Scale Screw Pressing Machine

A small scale screw pressing machine (Screw Press) is a general term for a press machine in the form of a pressurized force by rotating more than one set of outer bolts and inner bolts in a frame.The screw press can be divided into two ways, one is to apply static torque to the bolt to generate static pressure, and the other is to fix the rotating energy of the flywheel by bolts once for forming. As long as it is a press that generates a top and bottom forming torque by a spiral structure, it is regarded as one type of screw press.

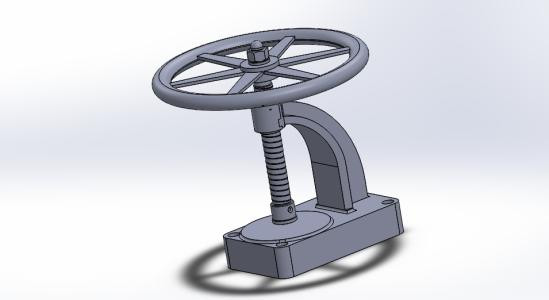

The screw press originated in Germany in the 15th century AD. A man named John Dondiberg invented a movable type printing machine, and the ink-coated movable type plate was pressed onto the paper by a screw device. This machine is used as a wooden bolt press for pressing grapes and olive oil, which is the origin of all pressure machines. It uses a static pressure method that gradually takes time to compress. In European museums, screw presses for hot forging by static pressure are also displayed. Presumably in the Middle Ages, it was used to make steel doors, windows and hardware for cities and churches. Later, the screw press for forging was developed to mount the runner on the upper end of the outer bolt shaft, and the flywheel was used to accumulate energy for driving.

Originally, the maneuvering rotary flywheel was manually operated. Later, because of the low efficiency and high manual work force, two friction discs that can be continuously operated were installed on the upper part of the machine, and the leather was successfully wound on the flywheel through the connecting rod to make them contact each other. Generate power. This is the friction screw press, which uses a friction drive. In the early stage, the friction screw press was controlled by the operator using a manual steering wheel to control the connecting rod. The degree of the up and down movement of the slider and the pressure of the pressing force depended entirely on the proficiency of the operator.

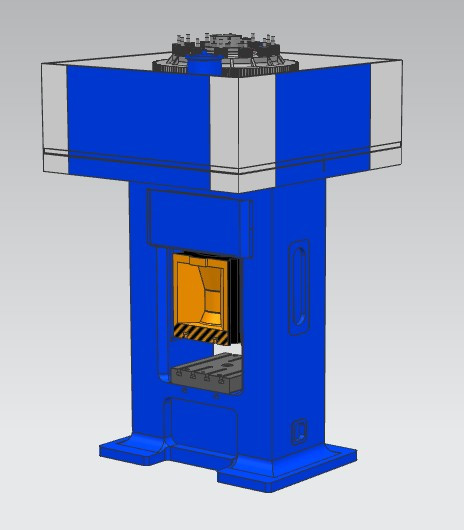

The screw pressing machine is mainly used for the processing of various high, medium and low grade refractory products, or the processing of various metal materials (cold, hot forging, cold forging of thin forgings, casting forging). In general, the lower part of the screw press is equipped with a forging ejector. The screw press has the functions of forging hammers, mechanical presses and other forging machines. It has strong versatility and can be used in die forging, blanking and drawing. In addition, the screw press, especially the friction press, has a simple structure and is easy to manufacture, so it is widely used. The disadvantages of screw presses are lower productivity and mechanical efficiency.

The basic working principle of electric screw press The flywheel, the sleeve shaft and the nut of the motor-driven screw press frequently move forward and backward together, the nut and the screw form a motion payment, and the nut drives the screw and the slider to move up and down to generate a striking force. The PLC-based control system is designed with several working blocks. The striking speed of each block can be adjusted by the corresponding electric; the number of striking of each block can be set by the corresponding counter. The instantaneous working state of the press can be collected for logical determination, and the control of the motor control and braking, the feeding and discharging device, and the pneumatic output control are completed. With the feeding and discharging device corresponding to various types of workpieces, the press can realize fully automatic work.