Oil Fractionation Equipment

Petroleum is a mixture of more than 8,000 hydrocarbons (and small amounts of sulfur compounds) of different molecular sizes. Petroleum must be processed before it can be used to make petroleum products suitable for various purposes. Fractionation is a common treatment method, which uses the principle of different molecular sizes and boiling points to separate hydrocarbons from petroleum, and then chemical treatment is used to improve the value of products.

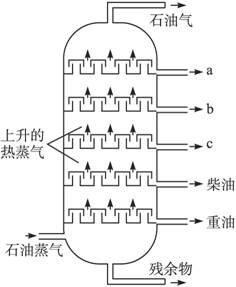

In industry, petroleum is heated to 400 ~500 degrees Celsiusto turn it into steam and then fed into the fractionator. In the fractionator, the higher the position, the lower the temperature. Petroleum vapor will gradually liquefy, cool and condense into liquid fractions during its ascent. Gaseous fractions with smaller molecule and lower boiling point rise slowly along the tower and condense at the top of the tower, such as fuel gas (Fuel Gas), liquefied petroleum gas (LPG.), light oil (Naphtha), kerosene (Kerosene), etc. The liquid fractions with larger molecule and higher boiling point condensate at the bottom of the tower, such as diesel oil, lubricating oil and wax. The viscous residues left at the bottom of the tower are asphalt and heavy oil, which can be used as raw materials for coking and asphalt production or as boiler fuel. Different fractions are collected at various layers and transported through conduits to the fractionator. These fractions are petrochemical raw materials, which can be made into many chemicals.

Petroleum products include crude oil, light oil, kerosene and heavy oil.Crude petroleum is a component with low fractionation temperature and small molecule. It can be used as fuel and gasoline, such as liquefied natural gas (mainly composed of methane, containing a small amount of ethane, propane, butane, ethylene) or liquefied petroleum gas (mainly composed of propane, butane, propylene, ethylene) or as solvent, such as hexane.Light oil, also known as petroleum brain, is a fractionated mixture with boiling point higher than gasoline but lower than kerosene. It can be divided into light petroleum brain and heavy petroleum brain. Petroleum brains can be used as gasoline and aviation fuel oil after dealcoholization and acidification. Light petroleum brains can produce gasoline or petrochemical raw materials with high octane content through medium reaction, such as benzene, toluene, xylene, etc., or ethylene, propylene, butene, pentane, aromatic hydrocarbons and carbon through cracking reaction.Gasoline and liquefied petroleum gas are produced from smoke or by hydrocracking. Heavy oil generally refers to the intermediate fuel which is made up of fuel oil or fuel oil mixed with diesel oil. Direct products can be classified into two types: fishing oil and boiler oil. After processing, lube oil, tar, petroleum coke, gasoline, liquefied petroleum gas and propylene can be produced.

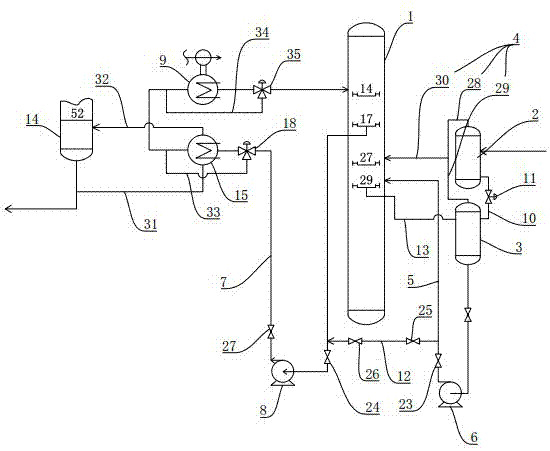

Crude oil contains a certain amount of impurities such as petroleum gas, water, salt and sediment. If these impurities are not removed, it will bring difficulties to the future process. The pretreatment step is to separate the petroleum gas through an oil-gas separator. Remove sediment and some water and salt from the sedimentation tank. Finally, desalination and dehydration are carried out under 15kV~25kV high voltage electric field.The top pumping oil extracted from the petroleum fractionation equipment is pumped to the heating furnace to be heated to 360 ~370 and then to the atmospheric distillation tower. After fractionation, low boiling gasoline fractions can be obtained from the top of the tower. When the condensate is cooled to 30c-40c, part of the fraction is used as the top reflux and the other part is used as the gasoline product. In addition, there are 1 to 2 secondary reflux. Atmospheric column generally has 3 ~ 4 side lines, kerosene and light diesel distillation respectively. Edge products refer to products with different boiling point ranges according to different needs of people, which are different in different processing processes. Some by-products were kerosene and light diesel, and the bottom product was heavy oil. Some by-products are kerosene, light diesel and heavy diesel, and the bottom product is atmospheric residue.

Crude oil can only fractionate fractions with lower boiling point in atmospheric distillation column. Some problems will arise when cracking and lubricating oil feedstocks with boiling point above 500 C are fractionated. Because these fractions contain macromolecular hydrocarbons above 450 C, cracking reaction will occur, which will deteriorate the distilled oil and produce coke, affecting the normal production. To solve this problem, distillation must be carried out under reduced pressure. Therefore, the heavy oil from the bottom of the atmospheric column is heated to about 410 C in the heating furnace and then fed into the vacuum fractionator. In order to keep the residual pressure at the top of the tower between 2.7kPa and 10.7kPa, it is necessary to use vacuum equipment to extract the non-condensable gas. At the same time, superheated steam is injected into the bottom of the vacuum tower to reduce the partial pressure of oil and gas in the tower and increase the fraction extraction rate. Heavy diesel oil is obtained at the top of the vacuum distillation column, light lubricant, medium lubricant and heavy lubricant are obtained at the side line, and residue is obtained at the bottom of the tower after stripping.