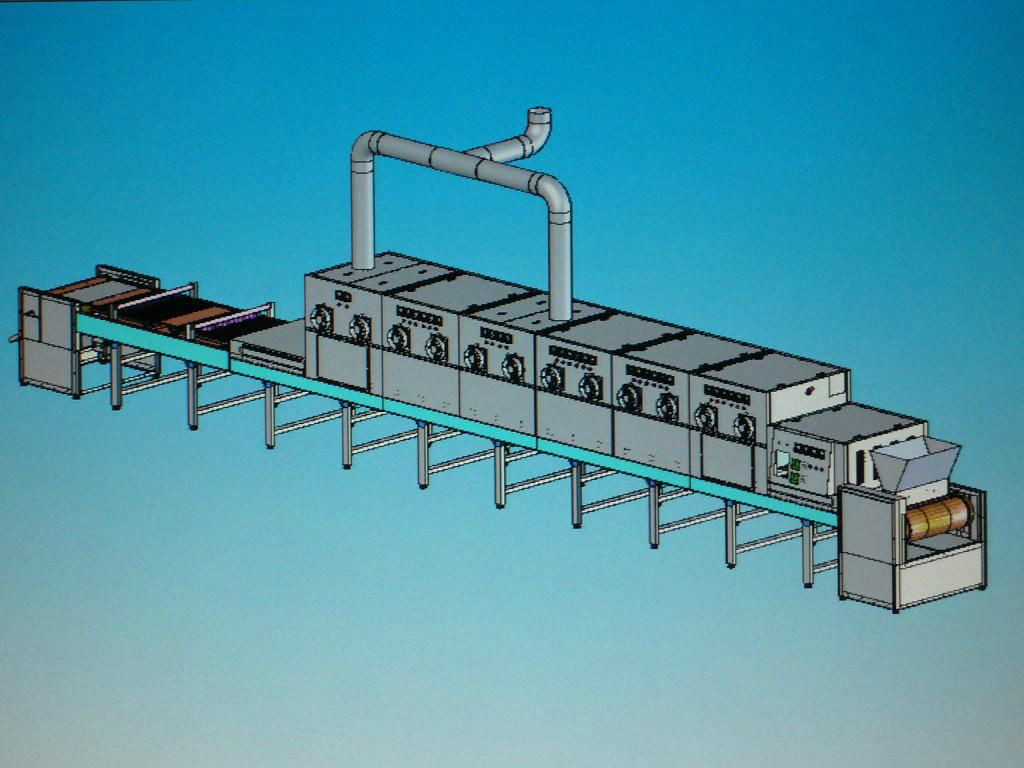

Multi-Layer Microwave Heating Machine

Principle of Rubber Vulcanization and Advantages of Microwave Rubber Vulcanization:

Raw rubber softens when heated, hardens and crisps when cooled, is not easy to form, easy to wear and tear, soluble in organic solvents such as gasoline, has double bonds in the molecule, easy to react with additives, and easy to aging. In order to improve the properties of rubber products, a series of processing processes should be carried out in the production of raw rubber. Under certain conditions, the raw rubber and vulcanizing agent in the rubber compound react chemically, making it cross-linked from linear macromolecules to three-dimensional network macromolecules, so that the rubber material has high strength, high elasticity, high wear resistance, corrosion resistance and other excellent properties. This process is called rubber vulcanization. Generally, the vulcanization process is divided into four stages: induction-pre-sulfur-positive sulfur-over-sulfur. In order to achieve this reaction, it is necessary to add energy to make it reach a certain vulcanization temperature, and then let the rubber heat preservation in the vulcanization temperature range to complete the whole vulcanization reaction.

Rubber vulcanization can be done by various methods. The traditional method is to use steam or far infrared heating vulcanization process. But because the heating temperature is slowly conducting from the outside to the inside of the medium, because the rubber material is a bad heat conducting material, for rubber, heating depends on the surface of the material to the inner layer of the heat transfer rate is very slow, most of the time spent on making the rubber reach the vulcanization temperature. Therefore, the heating time is long, the efficiency is low, and the uniformity of vulcanization is not good. Particularly, magnesium silicate (talc powder) was used in the old process to eliminate rubber adhesion, resulting in dust diffuse in rubber production workshop, and dust content in the air far exceeded the national environmental protection department standards. Moreover, the overall vulcanization state of rubber is not ideal, because, in the case of conventional heat conduction, the surface temperature of vulcanized rubber varies with the time of the inner layer, resulting in the phenomenon of non-uniform vulcanization.

Multi-layer microwave heating machine:It is the microwave energy penetrated into the heated medium and directly heated as a whole. Therefore, the heating is fast, efficient and energy-saving, which greatly shortens the vulcanization time of rubber, makes the heating uniformity better and the vulcanization quality higher. In a short time, it can go beyond the induction stage of rubber adhesion and enter the pre-sulfur stage. The operation of talc powder used in the old process can be removed to meet the environmental protection requirements. The production process can make most of the production processes concentrate on one production line, with high automation, low energy consumption, saving manpower, stable production, uniform product quality and so on. It has greatly improved. Labor conditions for production.

Microwave vulcanization technology has been rapidly promoted since its advent in the 1970s, especially the application of microwave continuous vulcanization production line in the production of rubber extrusion products. Its rapid development is unprecedented. Japan is a country with rapid development of microwave continuous vulcanization technology. Up to now, more than 450 microwave continuous vulcanization production lines have been produced, and more than 100 microwave continuous vulcanization production lines have been exported to countries all over the world. Microwave vulcanization technology has become a common mode of production in foreign industrialized countries. It is not only widely used for vulcanization preheating of various extruded rubber strips and hoses, but also for vulcanization preheating of various tires. China has imported dozens of continuous vulcanization production lines of microwave sealing strips from Germany, Japan, Spain, Britain and other countries. But the imported microwave vulcanization production line also has many problems, such as high price, high maintenance cost, unreasonable design of microwave cabinet, low microwave efficiency and insufficient automation of control. With the development of microwave energy application technology in China, a number of equipment using microwave vulcanization technology have been modified and modified in succession. Some imported equipment manufacturers, in cooperation with microwave energy application manufacturers, have begun to reform the existing problems of imported rubber vulcanization equipment, so that the product quality and output have been greatly improved. Since 2000, with the successful development of multi-tube microwave vulcanization equipment, the cost of equipment and the difficulty of maintenance have been reduced. At present, the technology of rubber microwave vulcanization has become more and more mature, and the equipment has been continuously improved. Efforts have been made in the direction of high automation, energy saving and environmental pollution reduction to meet the increasing needs of users. It has great potential and broad market.

Microwave heating machine is the core of the whole microwave vulcanization process. The uniform heating design of microwave heating equipment is particularly important. The uniform heating design of microwave heater is the premise of uniform vulcanization of rubber. In addition, the composition ratio, color depth and surface finish of rubber compound will vulcanize microwave rubber.