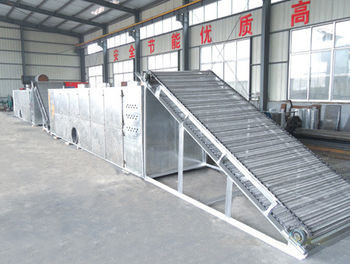

Rapeseeds Dehulling And Separating Microwave Drying Equipment

Frozen food is widely used in foreign countries, and a large number of frozen food are also used in domestic canned food, deep processing of meat products and Chinese fast food industry. In recent years, small packaged food has also entered the market, so thawing has become an important part of food processing. The so-called microwave thawing refers to raising the product temperature to a higher temperature, but still below freezing point, and small is to rise to environmental temperature, while the product is still hard. It is no longer frozen solid. When frozen food is treated by running water natural thawing method and high temperature air and steam heat source thawing method, due to the slow heat transfer, oxidation and bacterial reproduction are easy to occur on the food surface when the thawing temperature is reached.

Rapeseeds Dehulling And Separating Microwave Drying Equipment:

Although microwave thawing is a fast thawing method, it is limited by its thermal instability. When the whole frozen material is completely thawed by microwave, a large amount of microwave energy is absorbed on the surface of the material, and part of the ice melts rapidly into water, resulting in a rapid rise in surface temperature and local overheating phenomenon; while most of the frozen material is still in a freezing state, which can not achieve uniform thawing. Therefore, in order to complete uniform thawing, other processes should be combined.

Microwave drying equipment improves its own technology and equipment, but also combines with other drying technologies, such as hot air drying, true narrow drying, freeze drying, far infrared drying and so on, and develops in a deeper and wider direction. When microwave vacuum drying is applied to carrot drying, the drying time is greatly shortened, the oxygen content is low, and the loss of carotene is less.

The polar molecule of dielectric material changes its polar orientation with the direction of magnetic field in the electromagnetic field, which makes the molecule vibrate back and forth to produce friction heat. When microwave acts on materials, polar molecules (mainly water molecules) in materials change their polar orientation and vibrate at high frequencies under the action of alternating electromagnetic fields, which produces similar friction effects and increases internal energy. In this way, part of the bound water in the material is converted to free water molecule vaporization escape} H, which results in the shrinkage of the material kernels. At the same time, the free water molecule vaporized out acts on the material underwear under a certain pressure, destroying the material and underwear fitting. On the other hand, the bound water JF of the underwear and the hard shell under the action of microwave energy decreases, and the toughness and strength of the fiber structure decreases. In this way, the kernels, underwear and outer shell of the material deform differently under the action of microwave energy, which leads to the separation of kernels and underwear, and provides a good precondition for material peeling and de-coating.