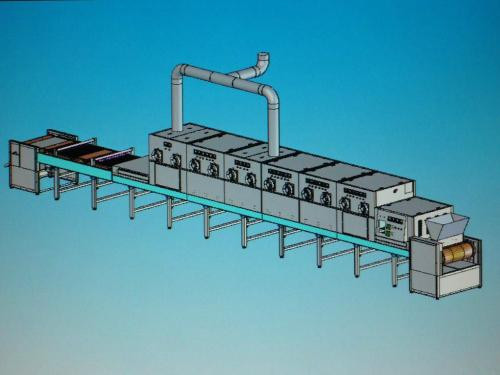

Edible Oil Refining Microwave Drying Machine

Working Principle of Microwave Drying Equipment:

Microwave is a kind of electromagnetic wave with very short wavelength. Its wavelength is between 1 m m and 1 m, and its corresponding frequency is between 300 GHz and 300 MHz. In order to prevent the interference of microwave to radio communication, broadcasting and radar, there are four frequencies for microwave heating and microwave drying, which are L-band, frequency 890-940 MHz, central wavelength 330 mm; S-band, frequency 2400-2500 MHz, central wavelength 122 mm; C-band, frequency 5725-5875 MHz, central wavelength 52 mm; K-band, frequency 2200-22250MHz, middle. The center wavelength is 8 mm. Only L and S segments are used in domestic microwave ovens.

Conventional heating, such as flame, hot air, electric heat and steam drying, uses the principle of heat conduction to transfer heat from the outside to the inside of the heated object and gradually increase the central temperature of the object, which is called external heating. It takes a certain amount of time for the central part to reach the required temperature, and longer for objects with poor thermal conductivity. The drying characteristics of microwave energy, microwave energy can penetrate the object inside and outside at the same time heating, the frequency is 245 MHZ, with 2.45 billion shocks per second, molecule friction between each other to generate heat, self-heating.

Composition Principle of Edible Oil Refining Microwave Drying Machine:

The microwave drying system is mainly composed of microwave generator, power supply, waveguide device, heater, cooling system, transmission system and control system.The microwave tubes used for heating and drying are mainly klystrons and magnetrons. Klystron is often used in high frequency or high power applications. Microwave generated by microwave tube is transmitted to heater through waveguide device. The heaters are mainly box type, plate type and waveguide type.

Microwave drying characteristics:

1. Short drying time, strong aroma of the product;2. Low drying temperature, uniform, bright color of the product;3. Selective heating. Because water molecules absorb microwave best, the part with high water content absorbs more microwave power than the part with low water content. This is the characteristic of selective heating, which can be used to achieve uniform heating and drying; 4. The direction of water and gas in drying and dehydration is from inside to outside. Therefore, microwave drying has puffing effect, which is helpful for subsequent comminution; 5. Energy saving and high efficiency. Microwave directly acts on the material, so there is no additional heat loss. The air in the furnace and the corresponding container will not heat, so the thermal efficiency is very high, and the production environment is also significantly improved. Compared with far-infrared heating, it can save 30% electricity. 6. Easy to control and advanced technology. Compared with the conventional method, the equipment is ready to use and has no thermal inertia and is flexible and convenient to operate.