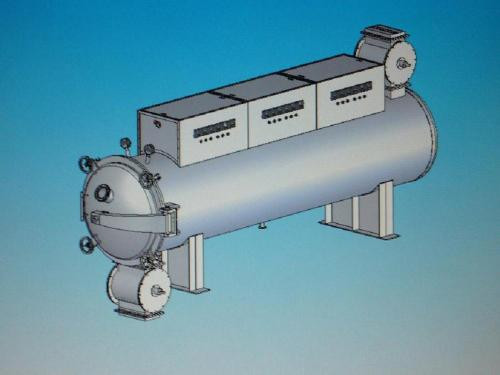

Vacuum Microwave Drying Machine

Vacuum Microwave Drying Machine:

Microwave vacuum cryogenic drying equipment uses radiation to transfer energy. It is the whole heating medium without any other heat transfer medium.

It avoids the disadvantage of too slow heat conduction speed, greatly shortens the drying cycle and reduces energy consumption. Therefore, under vacuum conditions, the moisture in the material evaporates at low temperature. To achieve the purpose of low temperature drying. Generally, microwave vacuum drying machine is mainly used for dehydration and drying of high value-added and heat-sensitive agricultural and sideline products, health products, food, medicinal materials, fruits and vegetables, chemical raw materials, etc. It is used for low-temperature concentration of chemical products, removal of crystalline water, drying of enzyme preparations, vacuum extraction of Chinese herbal medicines, and laboratories of scientific research institutes. Simply speaking, microwave vacuum dryer is suitable for those materials sensitive to high temperature, or after high temperature will affect the material.

Conventional vacuum drying is difficult to carry out air convection heat transfer under vacuum conditions. Only by means of heat conduction can the material be provided with heat energy. The heat transfer speed is slow, the efficiency is low, and the temperature control is difficult. Microwave heating is a kind of electromagnetic wave heating. Microwave directly acts on materials to heat both inside and outside at the same time. It does not need convection or conduction to transfer heat, so it has fast heating speed, high drying efficiency and easy temperature control.

The heating is uniform. Because microwave heating is used to heat the material from inside to outside at the same time, the temperature difference between inside and outside of the material is very small, and the inconsistency between inside and outside heating in conventional heating will not occur, thus resulting in the effect of expansion, conducive to crushing and greatly improving the drying quality. Easy to control, easy to continuous production and automation. Because microwave power can be adjusted quickly and without inertia, it is easy to control in real time, and can adjust temperature arbitrarily between 40 ~100%.Small size, easy installation and maintenance.From the characteristics described above, the remarkable economic and social benefits can be seen in energy saving, consumption reduction, product quality improvement, safety and hygiene, low cost of equipment investment, etc.