Microwave Vacuum Freeze Dryer

In recent years, with the innovation of science and technology and the industrialization of food processing, people's pace of life is accelerating and less and less time is spent on cooking. At the same time, with the improvement of living standard and the change of consumption concept, people's pursuit of food tends to be green, convenient and nutritious. Recently, convenience food has some problems, including the variety structure of convenience food is not comprehensive; The main food of meat is Fried and puffed, while the convenient food market of Chinese dishes is small and the production technology is not perfect. And the rise of freeze-drying technology can well meet people's needs for green, convenient and nutrition.

Vacuum freeze-drying technology is a new drying method to freeze water-containing material into solid, utilize the sublimation property of water under low temperature and low pressure, and dehydrate the material at low temperature to achieve drying. As vacuum freeze-drying technology is carried out in low temperature and low oxygen environment, most biological reactions are stagnant, and there is no liquid water in the process of treatment. The water sublimates directly in the solid state, so that the original structure and shape of materials are protected to the maximum extent, and finally high-quality dry products with both appearance and internal quality are obtained. At present, vacuum freeze-drying technology has been widely used in many fields, especially in food processing to obtain high quality dehydrated food.

Basic principle of microwave vacuum freeze dryer:Like other drying methods, to maintain the continuous sublimation drying, two basic conditions must be met, namely, the constant supply of heat and the continuous elimination of steam generation. At the beginning, if the material temperature is relatively high, the latent heat required for sublimation can be obtained from the sensible heat of the material itself. However, with the sublimation, the material temperature will soon drop to the temperature in equilibrium with the partial pressure of steam in the drying room. At this point, if there is no external heating, the sublimation drying will stop. In the case of external heating, if the steam generated by sublimation is not removed in time, the partial pressure of the steam will rise and the temperature of the material will also rise. When the freezing point of the material is reached, the ice crystals in the material will melt and freeze drying will be impossible.

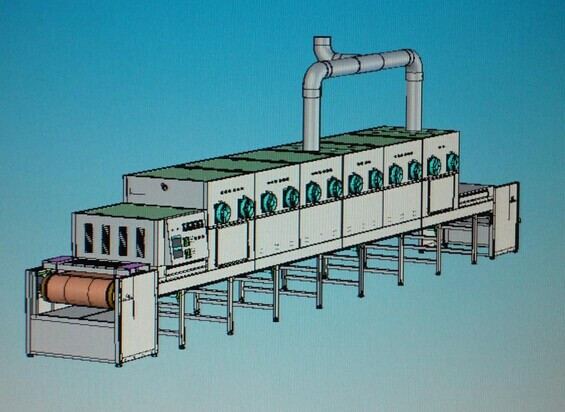

Main microwave drying equipment:The main equipment for freeze-drying food production is the vacuum freeze-drying set for food. The performance, energy consumption and operation automation of the set determine the technical level of the freeze-drying food production enterprises. The freeze-drying machine for food is divided into intermittent and continuous types. Continuous units are still rare in domestic enterprises. Intermittent lyophilizer is composed of drying box, heating system, vacuum system, refrigeration system, control system and so on.