Soap Making Microwave Dryer Machine

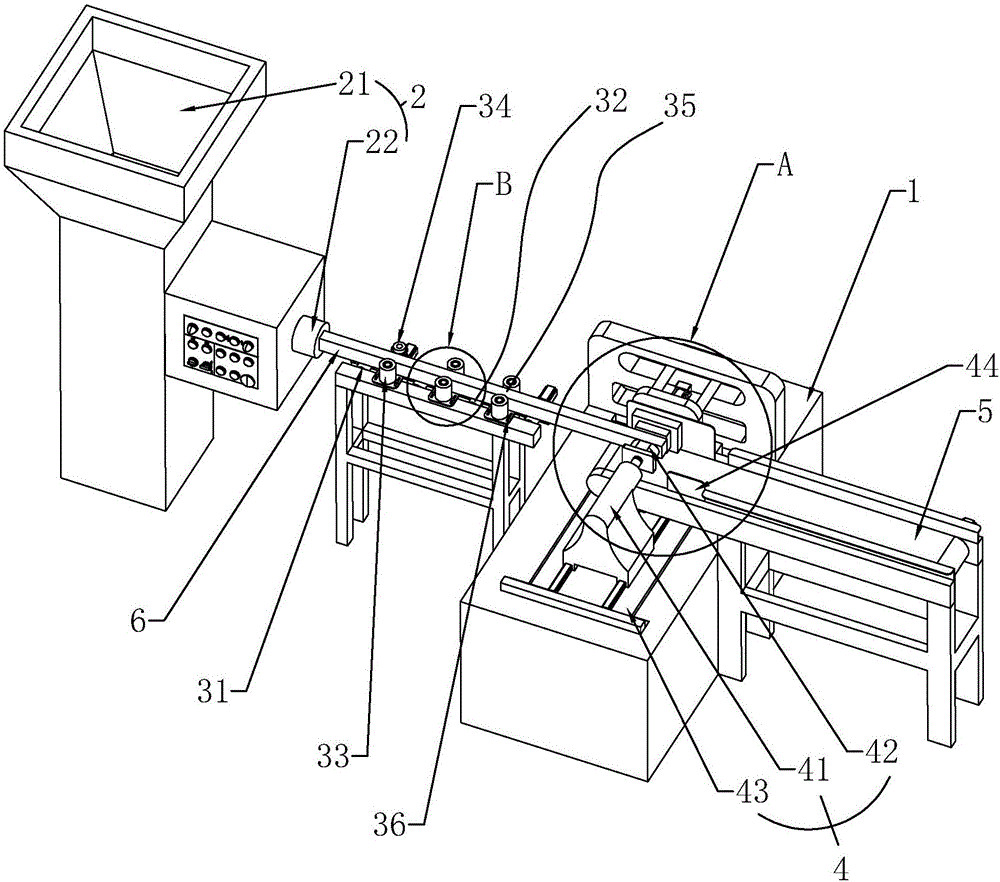

Traditional frame type cold plate mass production laundry soap, room pressure drying room produce incense soap, transparent soap occupies a large area of the ground, the amount of labor is large, large amount of waste soap and must be reprocessed to reduce the grade of products, and also cause pollution to the environment, the quality of the product soap is low, not suitable for the production of high-grade soap, laundry soap. The soap making microwave dryer machine showed its unique progressiveness in the production of fertilizer soap, which changed the traditional soap making process, improved the automation process of production and continuous production is the best equipment for producing high-grade soap.

Vacuum cooling soap production is often used in laundry soap production. Under the vacuum strip, the liquid soap base is adiabatic evaporation in the microwave drying equipment, that is, the heat amount is brought into the soap base with "ye-xiu", and the soap base is instantly cooled to the vacuum degree at the boiling point of the water to evaporate its own water. Such as lost into the liquid MuZao base temperature is 80 ℃, due to the temperature of the liquid soap base made greatly over the boiling point of the water temperature under the condition of vacuum, and make the liquid soap base rapid evaporation of water points, da xi drying requirements, at the same time make the soap base is cold to the vacuum degree of boiling point temperature of the water. From a liquid state to a solid state.

Air drying soap is commonly used in the production of soap, its basic principle and true air cooling production of laundry soap, but there are differences, area is fragrant soap production is mainly used as drying, because the fragrant soap soap base to take off in addition to water more, have to soap baseband into the heat is not sufficient alone to the required moisture to dry, also must before off heat steam heating, a warm up to 50 a 1 7 0 ℃. To sum up, according to the specifications and requirements of the product, satisfactory soap products can be obtained in the production only by grasping the composition of soap components, vacuum degree, water temperature, liquid soap base temperature and the flow rate of liquid soap base into the vacuum cattle handling equipment.