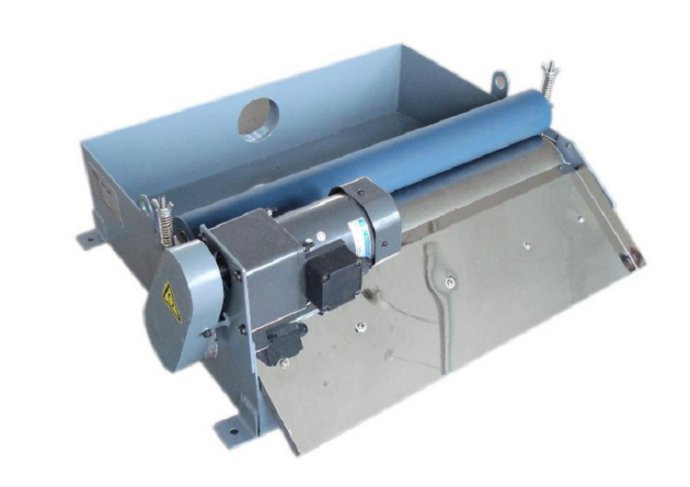

Magnetic Separator Microwave Machine

Magnetic separator microwave machine is a new type of grinding machine cutting and filtering equipment, which is specially used in machine tool cutting and hardware processing industries. The working principle of magnetic separator is introduced below.

The magnetic separator microwave machine is used to purify the coolant of grinder and other machine tools. The iron chips in the coolant are sucked out by the magnetic drum of the separator to keep the coolant clean. The use of magnetic separator can reduce the number of wheel correction, improve the surface smoothness of workpiece, and prolong the service life of grinding wheel and coolant.In grinding process, with the improvement of machining accuracy, high-speed grinding and strong grinding technology develop rapidly. Besides choosing reasonable grinding parameters, the circulating quality of grinding fluid must also be improved.

The magnetic separator is also very important to the separation degree of magnetic iron chips. Most people do not know what factors determine the separation function of magnetic separator. They think that magnetic separator with strong adsorption is a magnetic separator with high performance. Usually the degree of separation of impurities by magnetic separators mainly depends on the magnetic rod's adsorption force, the detachment effect of debris and the speed and rotation mode of the magnetic rod. The magnetic attraction of the magnetic rod mainly depends on the magnetic force of the rod, the layout of magnetic induction lines and the adsorption area. The magnetic induction lines are evenly distributed on the surface of the rod, so that the magnetic force of the rod can be maximized everywhere.

Magnetic separator is used to purify machine tool coolant and other grinder coolant, because the separator itself has a strong magnetic force, can be some of the coolant and cleaning liquid iron cutting and a series of residues, through magnetic force to achieve automatic separation. It is a good thing for manufacturers to keep cutting fluid clean, improve the performance of industrial processing and the quality of processed products, and reduce the cost of industrial processing and improve production efficiency. It also reduces environmental pollution and the environmental costs paid by society for production.

Magnetic separators are widely used in industrial applications. They can effectively separate and filter coolants and other liquids. The places of application are mostly coolants of various grinders, electrical processing equipment and coolant purification of grinder finishing.