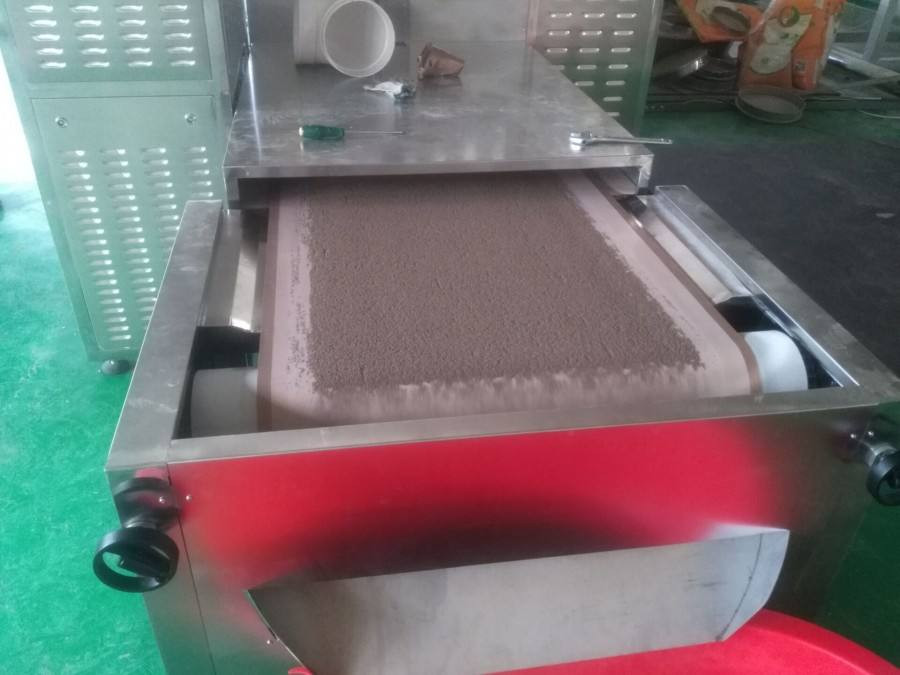

Feed Microwave Drying Machine

Microwave drying machine have been successfully used in agriculture, forestry, food, pharmaceutical, textile, plastics and other industries.

Microwave energy is an efficient, safe and environmentally friendly energy source developed and matured with radar technology after the Second World War. Traditional pellet feed quenching and granulating process generally uses steam energy, which is not only because of its high requirements on material moisture, steam pressure and modulation time, but also because the boiler used is special equipment. The slight improper operation will affect the quality of the pellet material. The output will also reduce the service life of machinery and equipment, and it will lead to major accidents such as boiler explosion.

Drying effect of feed microwave drying machine: The feed contains a variety of polar substances. These polar substances vibrate at high frequency under the action of microwave field, collide with each other, and generate heat by friction. Water is a polar substance. Microwaves have a heating property, and the water inside the feed is heated and vaporized very quickly. Due to the permeability of the microwave, the particles are heated both inside and outside, the particles are evenly heated, and the water evaporates quickly.

Microwave improves the water resistance of soft grain feed. The water resistance of soft granular feeds after microwave treatment was significantly improved. The microwave energy acts directly inside the particle to make it inside the particle.It is consistently affected by water and heat. Under the action of water and heat, the starch contained in the grain feed is gelatinized, the protein is uniformly modified, the starch and the protein are changed from a granular shape to a gel shape, and the other components are bonded to form the whole particle. Thereby improving the water resistance of the pellet feed.Microwave sterilization: After the powder is applied by microwave, the temperature rises and the water vaporizes.Thus forming an ideal moist heat sterilization environment.

Feed microwave dryer line features: high energy conversion efficiency, fast heating. The microwave oven itself does not generate heat, but the microwave energy penetrates the material, causing the polar molecules in the material to rub against each other to generate heat. Therefore there is no energy loss. The puffing effect is obvious. The rapid heating effect of the microwave makes the water molecules inside the material vaporize rapidly and achieve the purpose of puffing. Low temperature sterilization and less loss of nutrients. Microwave sterilization is carried out under the dual effects of thermal and non-thermal effects of microwaves, and satisfactory sterilization can be obtained at a lower temperature and in a shorter period of time than conventional temperature sterilization. Easy to use. Microwave power and conveyor speed can be adjusted steplessly, without thermal inertia, can be opened and stopped, easy to control. The size of the equipment can be customized according to the actual production requirements, and there will be no situation where the power of the equipment is too large, waste is generated, and the production power is small, and the production needs cannot be realized.