Design of industrial food freeze dryer

The working principle and basic structure of food freeze-dryer and medicine freeze-dryer are the same. Microwave drying machinery and equipment are composed of drying bin, water vapor condenser (water catcher), refrigeration system, heating system, vacuum exhaust system and monitoring and control system. But there are many differences between freeze-dried food and freeze-dried drugs. If the food is mostly solid loose matter, the common solution point is generally higher, the product loading per unit shelf (heating plate) area is large, and the sublimation heat required is more; whereas the drug is the opposite. Therefore, the operating pressure, temperature and heating mode of food freeze-dryer are different from those of drug freeze-dryer.

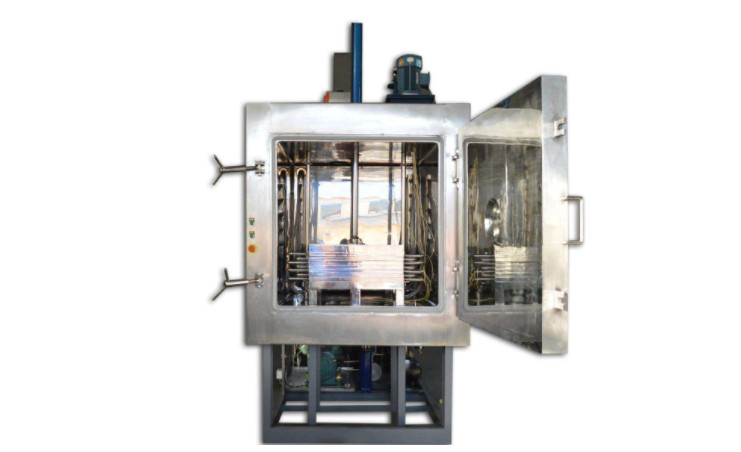

Some of the rational structures in pharmaceutical freeze-drying machines are not necessarily reasonable in the food freeze-drying machine. Next we first discuss the overall structure design. 1.1 Continuous and batch continuous food freeze-drying machines (Fig. 1) are food processed before cleaning, moulding and mildewing. According to the adjusted step length, a plate of food is evenly passed through the pre-frozen tunnel, the vacuum isolation chamber at the entrance of the drying bin, the drying bin and the drying bin in turn. The warehouse is exported to the vacuum isolation room and sent to the packaging process. The drying bin is divided into several sections. The working pressure and temperature of each section are adjusted according to the freeze-drying curve of the product. The freeze dryer has high production efficiency, low energy consumption, high automation, and low production cost when the product is in large batches.

But the production process is complicated. Every product begins to freeze-drying and ends freeze-drying. The machine has a freeze-drying cycle time and no-load operation. The price of equipment is much higher than that of batch type. Therefore, this kind of freeze-dryer is only suitable for mass production of single products, such as coffee and tea. If the batch size of each product is too small and the relative assistant time (adjusting machine, no-load cycle, etc.) increases, its production efficiency and energy consumption index may be worse than batch type.

(L) the utilization rate of the former equipment is low. The cost of unit products is high. Because the additional equipment (existing refrigerators) cost of special freezing cold storage is very small, which is only one-tenth of the investment of freezing dryer, and generally needs 2-h4 for each pre-freezing. It is not economical to use expensive freezing dryer to do the work of low-cost freezing cold storage. (2) the former equipment is inefficient. In addition to the reduction of production efficiency by pre-freezing, the contact heat transfer mode (see below) and the heat and cold offset in the process both reduce production efficiency.

(3) the former has large energy consumption per unit product. Warehouse pre-freezing must also reduce parts (shelves, brackets, cylinders, etc.) and cooling medium to near or below the temperature of frozen products. When sublimating, it is necessary to raise parts and cooling medium in the box with very low temperature to near or above the shelf temperature. This ineffective heat and cold can offset each freezing. The dry cycle needs to be carried out, so that the total energy consumption per unit product is greatly increased. (4) Pre-freezing speed is slow, which may cause the product ice crystal to be too large, destroy the cell tissue of the product, and reduce the quality of the product. The freezing of out-of-warehouse cold storage is generally blown freezing, which can form continuous dendritic ice crystals to meet the needs of sublimation water vapor passage porosity. The freezing in-warehouse is contact heat transfer and natural convection, and the freezing speed is slow. It is possible that the freezing time is long near O C, and the growth of ice crystals is too large. Product quality. Therefore, according to the quality and cost of freeze-drying, pre freezing and drying are beneficial. 1.3 the relative of the drying bin and the water trap.