Design of small grain dryer

The development of grain dryer in our country started from the early liberation of Japan, the former Soviet Union and other foreign dryers. Because of the complex structure of the grain dryer at that time, it consumed more steel and had a high cost, so it was only used in some farms and grain depots. In the late 1970s, relevant scientific research organizations began to develop and design dryers for production in China, but they were also limited to the use of farm production companies and rural production teams.

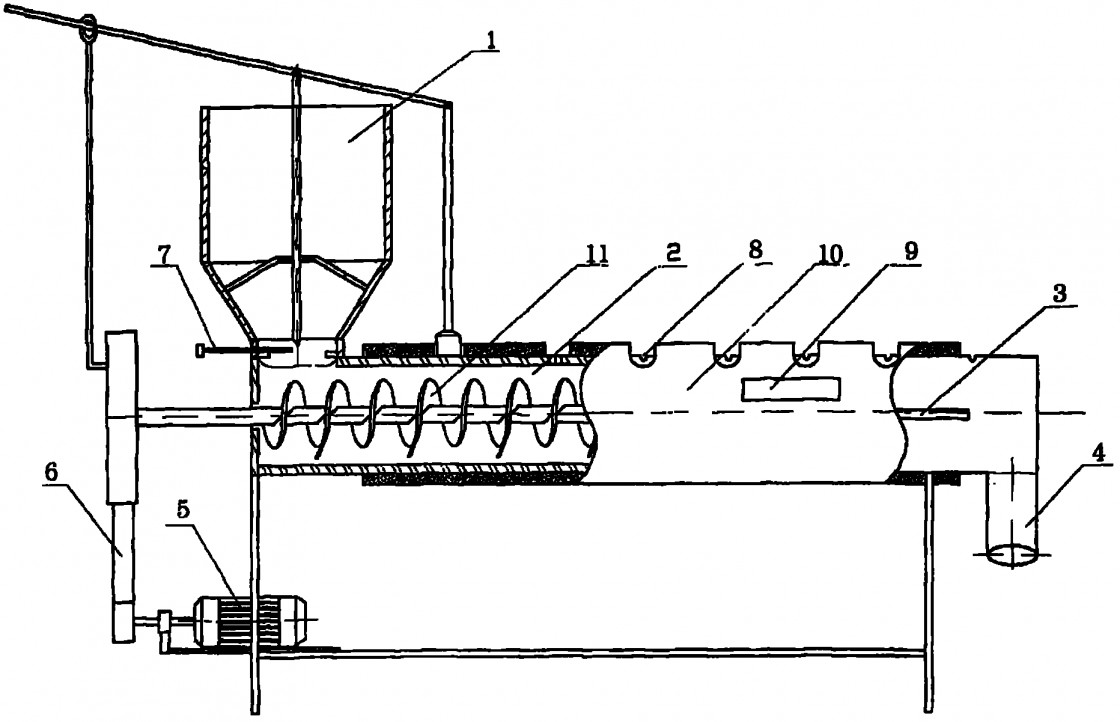

Microwave mechanical drying equipment

With the deepening development of rural reform, the rural economy and agricultural productivity have been improved rapidly, and dryers are also developing in the direction of specialization. With the development of China's machinery industry, the main types of grain dryers are simple stacking dryer, fountain dryer, low temperature dryer and microwave dryer. On the basis of the existing hot air drying design technology, the design of small grain dryer incorporates two structures: supply duct and blade. Hot air is injected into the box in all directions from inside to outside through the supply duct, and the role of blade in throwing grain is added to make the hot air contact with grain better and make the grain receive uniformly. Heat can effectively achieve the purpose of grain drying.

When working, the grain is poured into the box from the grain inlet, and the motor provides power to drive the overall rotation of the box; during the rotation of the box, the fan blows into the hot air and enters the box through the air supply pipe, which runs through the whole box and distributes fine holes in the pipe, so as to realize the uniform dispersion of the hot air in the box. The design of the blade can achieve good aerodynamic characteristics and make full use of the hot air to dry the grain; the added grain circulates under the action of the box and the blade, and the overall rotation of the box and the blade design of the similar waterwheel principle are conducive to the full mixing of the grain and reduce the impact of the mixing process on the grain. Mechanical extrusion reduces grain burst rate, makes grain fully contact with hot air, and improves drying efficiency. After drying, the grain can be poured out from the outlet and packed by tilting the box down at a certain angle.

According to the design, the speed of the motor is 20R /min, and the maximum drying quality is 40kg. Drying requirements: the temperature inside the drum is controlled at about 45 degrees Celsius. In order to reduce the bursting waist rate, after drying for a period of time (about 30 minutes), the hot air blower and motor were stopped and the soot was slowed down. The experimental results show that the humidity decreases after the slow-thawing, and returns to the value before the slow-thawing when the humidity is dried again; after the second slow-thawing, the grain is poured out and weighed, the quality is 20 kg, and then dried again. When the humidity reaches the value of air humidity, the drying stops and the box opens, so that the air and the inside of the box can be dried again. External air convection; after convection 20min, the grain is poured out for weighing, and the mass is 19.9kg. According to the verification regulation of grain moisture tester approved by the State Technical Supervision Bureau

The grain dryer has stable functions, can better carry out drying operations, and has low production cost, high drying efficiency, low drying cost, simple operation and easy to move, so as to meet the needs of small farmers in the south. However, the machine also has some problems, such as the inability to carry out various types of grain drying, time-consuming, manual bagging after drying, and so on, which need further improvement.